Introduction

In hazardous environments such as coal mines, petrochemical plants, chemical processing facilities, and oil & gas fields, conventional electronic displays cannot be directly applied. This is because LCD panels and their driver circuits may generate sparks, arcs, or heat during operation, which could ignite surrounding flammable gases or dust. Therefore, specialized explosion-proof displays compliant with ATEX / IECEx standards must be used. These devices feature special designs in their housings, sealing methods, heat dissipation, and internal structures.

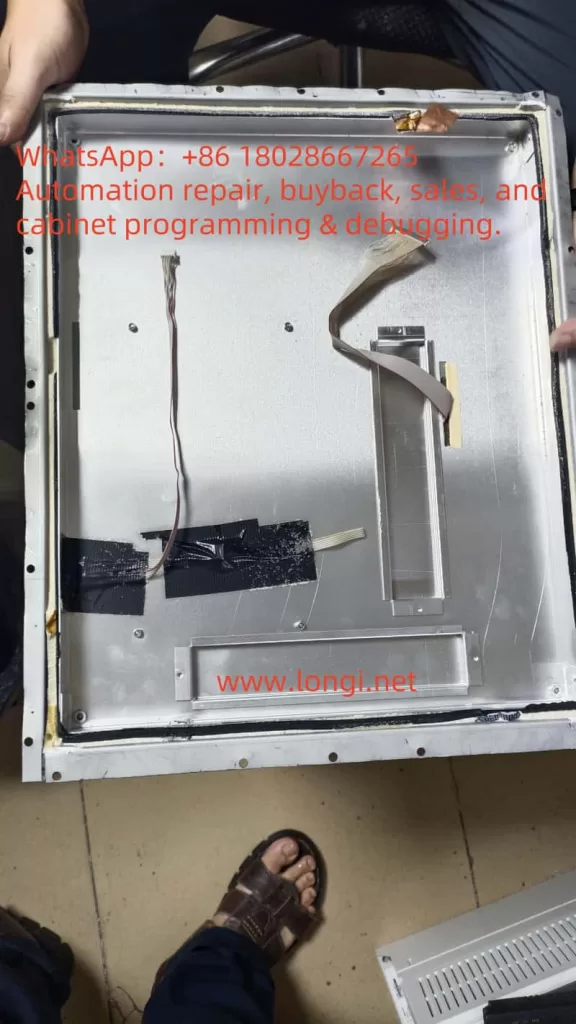

During the repair of a customer’s explosion-proof display, the author discovered something unusual: apart from the LCD module and driver board, the interior was filled with a large quantity of uniform, tiny plastic beads—enough to collect half a bowl after disassembly. At first, the purpose of these beads was unclear, and some speculated that they might be desiccants. However, further investigation revealed that these microbeads play a crucial role in the explosion-proof design. This article explores their functional mechanism, possible material types, and alternative options.

I. Basic Requirements of Explosion-Proof Displays

1. Explosion-Proof Standards

According to the IEC 60079 series of international standards, explosion-proof electrical equipment must prevent the following hazards:

- Arc and spark leakage: Switching elements, relays, or LCD driver ICs may generate sparks.

- Hot surfaces: LED backlight drivers or power modules may heat up.

- Internal explosions: If components burn or fail, flames must not propagate outside the enclosure.

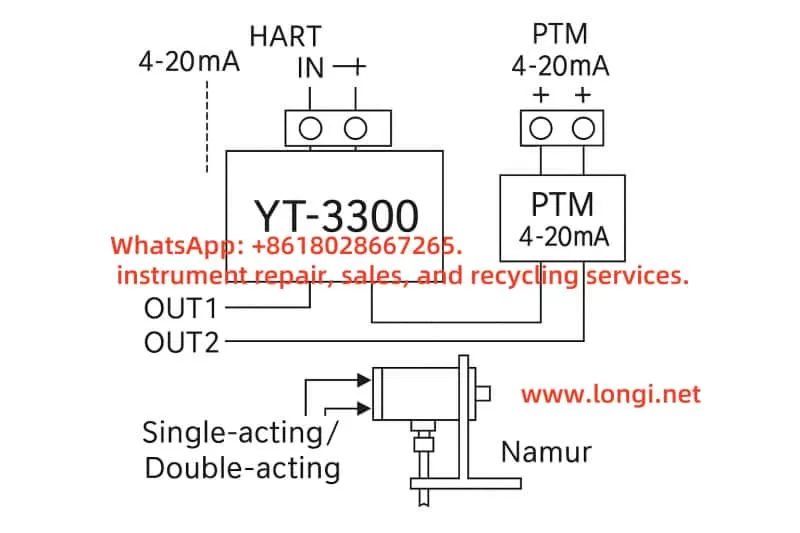

Common protection methods include Flameproof (Ex d), Intrinsic Safety (Ex i), Increased Safety (Ex e), and Powder Filling (Ex q)—the method most relevant to this discussion.

2. The Principle of Ex q Powder Filling

Ex q protection involves filling the enclosure with fine particles or powder so that no free air cavities remain inside. Any arcs, sparks, or flames are effectively blocked from propagation. Typical fillers include quartz sand, glass microbeads, or flame-retardant polymer beads.

Advantages include:

- Friction between particles dissipates energy and prevents flame spread.

- The filler provides thermal insulation, slowing heat transfer.

- Properly selected materials are non-flammable and ensure safety.

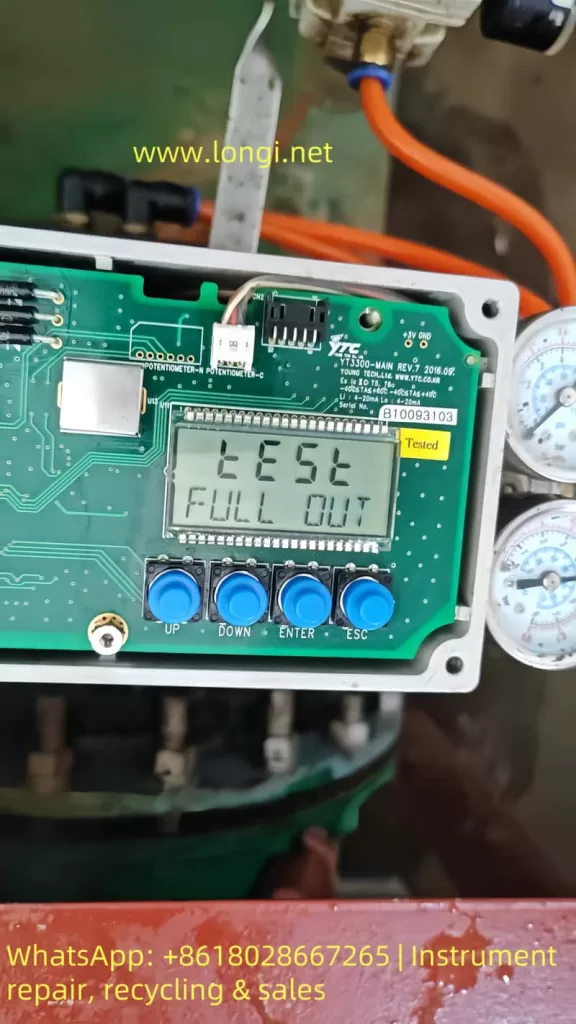

II. Observations During Repair

Upon disassembly, it was noted that all housing seams were sealed with adhesive. Inside, the cavity was densely packed with white, spherical beads of about 0.5–1 mm diameter, lightweight and smooth.

Initial suspicion that these might be silica gel desiccants was soon dismissed:

- The sheer volume was far beyond what moisture control would require.

- Desiccant beads are typically porous and often color-indicating (blue/orange).

- Their primary purpose is moisture absorption, not shock absorption or flame suppression.

Thus, these were confirmed not to be desiccants but rather specialized filler beads for explosion-proof applications.

III. Likely Material Types

By comparing common industrial fillers, the beads are most likely one of the following:

1. EPS / EPE Foam Beads

- Appearance: White, lightweight, uniform diameter.

- Advantages: Excellent energy absorption, cushioning, and vibration damping; inexpensive.

- Limitations: Low heat resistance unless treated with flame retardants.

2. Hollow Glass Microspheres

- Appearance: Transparent or white, smooth spherical particles, 100–500 μm typical size.

- Advantages: High-temperature resistance, non-flammable, chemically stable.

- Limitations: More expensive, fragile.

3. Expanded Perlite Granules (Glassy Beads)

- Appearance: Irregular, porous mineral-based particles.

- Advantages: Fireproof, high-temperature resistant, widely used in construction insulation.

- Limitations: Dust generation, irregular shapes, not suitable for close contact with electronics.

Based on their smooth spherical shape, uniform size, and dense packing, the filler in this display is more consistent with flame-retardant EPS/EPE beads or hollow glass microspheres, rather than perlite-based construction materials.

IV. Functional Mechanism of Beads in Explosion-Proof Displays

1. Energy Absorption

In the event of arcs, short circuits, or small internal explosions, the beads absorb shock energy through inter-particle friction, preventing flame penetration.

2. Elimination of Cavities

By filling every space inside the enclosure, no free air volume remains, reducing the risk of flammable gases accumulating.

3. Thermal Insulation and Flame Retardancy

The filler layer weakens heat conduction. Even if some circuits generate heat, it is not quickly transferred to the housing. Flame-retardant treated beads will not sustain burning.

4. Shock and Vibration Damping

Explosion-proof displays are often installed in environments subject to mechanical vibration. The filler beads protect LCD panels and circuits by cushioning against long-term vibration.

V. Can “Glassy Perlite Beads” Be Used as a Substitute?

Products such as glassy perlite beads (expanded perlite) are commonly sold for construction insulation. While fireproof, they are not suitable substitutes in this context because:

- Irregular shapes make them pack poorly, leaving gaps.

- High dust levels may contaminate electronic boards.

- Low mechanical resilience means they crumble under vibration and do not cushion effectively.

Thus, glassy perlite beads are not recommended as replacements for the original filler.

VI. Suitable Substitutes and Purchasing Advice

1. Flame-Retardant EPS Beads

- Recommended size: 1–3 mm diameter.

- Advantages: Lightweight, easy to fill, cost-effective.

- Requirement: Must meet certified flame-retardant grades (e.g., UL94 V-0 or B1).

2. Hollow Glass Microspheres

- Recommended size: 100–500 μm diameter.

- Advantages: High-temperature resistance, non-flammable, smooth surface.

- Suitable for higher-spec safety environments.

3. Procurement Channels

- Chinese e-commerce: Search for “阻燃EPS微珠” or “中空玻璃微珠”

- International suppliers: Brands such as Storopack and SpexLite offer filler beads with technical documentation.

- Explosion-proof equipment distributors: Some suppliers provide certified filler material specifically for Ex q applications.

VII. Conclusion

The beads observed inside the explosion-proof display are not desiccants but specialized filler materials that comply with the Ex q powder filling principle (IEC 60079-5). Their functions include absorbing energy, eliminating cavities, insulating against heat, and damping vibration.

Based on observed characteristics, they are most likely flame-retardant EPS/EPE foam beads or hollow glass microspheres, not perlite-based construction fillers. For repairs or replacement, it is critical to choose certified, flame-retardant, low-dust spherical beads, typically 1–3 mm in diameter, to ensure compliance with explosion-proof safety standards.

This choice directly affects not only the reliability of the equipment but also intrinsic safety in hazardous environments. Therefore, service personnel must reference relevant standards and confirm flame-retardant certification when selecting replacement materials.