Introduction

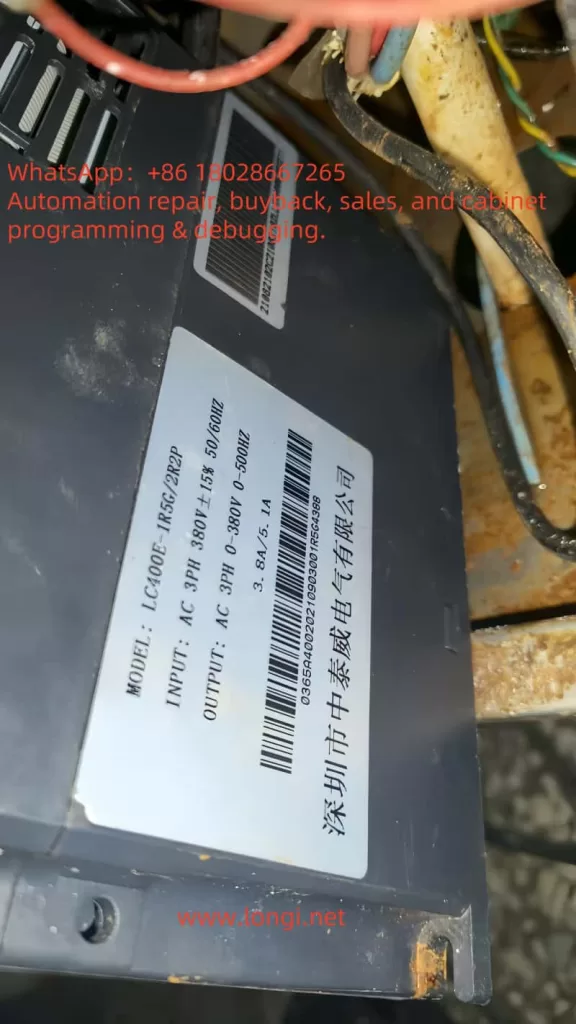

In the realm of modern industrial automation, variable frequency drives (VFDs) serve as the cornerstone of motor control systems. They enable precise regulation of motor speed and torque, facilitating energy efficiency and optimal performance, particularly in applications such as machinery manufacturing, fan and pump loads, and elevators. ZTV (Zhong Tai Wei), a prominent Chinese manufacturer of VFDs, is renowned for its LC400E series, which offers high cost-effectiveness and reliable operation. This series supports three-phase 380V input, with power ratings starting from 1.5kW and extending to higher capacities, making it suitable for diverse industrial environments. However, like all electronic devices, the LC400E VFD is susceptible to faults during operation. Among these, the Err42 error code is a frequently encountered alarm, signifying an “excessive speed deviation fault.” This issue can halt motor operation, disrupt production efficiency, and potentially lead to equipment downtime.

Based on the ZTV LC400E VFD manual and the provided fault screenshots, the Err42 fault typically arises from a significant discrepancy between the motor’s actual speed and the set speed. If this deviation exceeds a predefined threshold, the VFD initiates a protective shutdown to prevent further damage to the motor or load. Understanding and resolving this fault not only allows for swift restoration of operations but also enhances the overall reliability of the equipment. This article delves into the Err42 fault, covering its definition, root cause analysis, diagnostic procedures, resolution strategies, preventive measures, and real-world case studies. It aims to provide a structured, logically sound, and practical guide for engineers and maintenance personnel. The content draws from the official manual, on-site experiences, and relevant technical literature to ensure accuracy and applicability.

Overview of Err42 Fault

The Err42 fault manifests on the LC400E VFD’s display screen in red text, often accompanied by a buzzer alarm or flashing indicator lights. The code “Err42” directly translates to “excessive speed deviation,” representing a protective mechanism primarily in closed-loop control modes. In the VFD’s operational principle, motor speed control relies on comparing feedback signals (such as those from an encoder providing actual speed) with the setpoint speed. When the actual speed deviates excessively from the setpoint, the VFD triggers this alarm.

Specifically, the LC400E series supports various control modes, including V/F control, open-loop vector control, and closed-loop vector control. In closed-loop mode (when parameter P0-01 is set to 1), encoder feedback is critical. If the deviation is too large, the VFD immediately ceases output to avert motor instability or overload. Symptoms include: the motor starting briefly before stopping, the VFD panel displaying Err42, abnormal fluctuations in output current, and possibly mechanical vibrations or unusual noises. According to the manual, this fault’s trigger threshold correlates with parameter P2-10 (speed deviation setpoint), typically defaulting to a percentage like 5%-10%, depending on the model.

Why is this fault significant? In industrial settings, excessive speed deviation not only interrupts production but can also cause chain breaks, product defects, or safety hazards. For instance, in fan applications, unstable motor speed leads to fluctuating airflow, compromising ventilation systems; in pump loads, it results in pressure instability, affecting process flows. Statistics indicate that speed-related issues account for about 15%-20% of VFD faults, with Err42 being a typical example. Early identification and resolution can substantially reduce downtime and maintenance costs.

Possible Causes of Err42 Fault

To effectively address the Err42 fault, a thorough examination of its underlying causes is essential. Drawing from the LC400E manual and the fault table screenshot, here are the five primary causes, each explained with practical scenarios:

- Incorrect Encoder Parameter Settings: In closed-loop vector control mode (P0-01=1), the encoder is pivotal for speed feedback. If parameters such as P9-69 (encoder type) or P9-70 (encoder pulses per revolution) are misconfigured, the VFD cannot accurately interpret the actual speed, leading to erroneous deviation calculations. For example, if the actual encoder is incremental but set as absolute, signal mismatches occur.

- Incomplete or Absent Motor Auto-Tuning: The LC400E VFD mandates motor parameter auto-tuning (initiated via P9 group parameters) before use. If tuning is interrupted (e.g., due to power fluctuations) or skipped, the VFD’s understanding of motor parameters like resistance and inductance becomes inaccurate, impairing speed control precision. The manual stresses that auto-tuning is a prerequisite for closed-loop control, and neglecting it often triggers Err42.

- Too Small Speed Deviation Setpoint: Parameter P2-10 defines the allowable speed deviation threshold. If set too low (below the actual load fluctuation range), even minor deviations can activate the alarm. This is common in applications with variable loads, such as conveyor belts where torque spikes during startup.

- Sudden Load Increases: External factors like mechanical jamming, overload, or loose transmission chains can cause the actual motor speed to lag behind the setpoint. While the VFD’s U, V, W phase outputs to the motor remain normal, excessive load resistance accumulates deviation.

- Wiring Abnormalities: Issues at the VFD’s output terminals U, V, W and the motor connections are the most prevalent hardware faults. These include cable breaks, poor contacts, incorrect phase sequences, or grounding problems, which disrupt feedback signals or output power, indirectly exacerbating speed deviations.

Additionally, environmental factors such as high temperatures, dust accumulation, or unstable power supplies can indirectly contribute to Err42. In practice, these causes often interplay; for instance, parameter errors can amplify load effects, resulting in frequent faults.

Diagnostic Steps for Err42 Fault

Diagnosis is the cornerstone of fault resolution and should be conducted systematically. The following process is derived from the LC400E manual, prioritizing safety (power off during operations):

- Initial Equipment Status Check: Observe the VFD panel to confirm the Err42 code. Record the alarm time, operating frequency, and load conditions. Use a multimeter to measure input voltage (AC 3PH 380V ±15%), ensuring it’s within normal limits.

- Parameter Settings Review: Enter parameter mode (by pressing the PRG key) and verify if P0-01 is set to 1 (closed-loop mode). Check P9-69 and P9-70 for encoder parameter alignment with actual hardware. The manual recommends cross-referencing motor nameplate data.

- Motor Auto-Tuning Test: If auto-tuning hasn’t been performed, initiate it via P9 group functions for static or dynamic tuning. This requires no-load conditions and lasts a few minutes. After completion, restart the VFD to see if the fault recurs.

- Speed Deviation Measurement: Monitor group parameters (e.g., d0-00 for actual speed, d0-01 for setpoint speed) to calculate the deviation. If it consistently exceeds the P2-10 setpoint, classify it as a software issue.

- Hardware Inspection: After powering off, examine U, V, W output cables. Use a megohmmeter to test insulation resistance (>5MΩ is normal). Manually rotate the motor shaft to check for mechanical resistance. If available, use an oscilloscope to monitor encoder signal waveforms for distortions.

- Environmental Assessment: Inspect the VFD’s installation site to avoid humidity or excessive heat (operating temperature: -10°C to 40°C). Clean dust and confirm fan operation.

Document the diagnostic process in a log for future reference. If initial diagnostics fail, draw from experiences with similar brands, like ZHZK inverters where Err42 often stems from control mode conflicts.

Solutions for Err42 Fault

Tailored to the identified causes, here are step-by-step solutions. Ensure equipment is powered off and operations are performed by qualified personnel:

- Correct Encoder Parameters: Access the P9 group, set P9-69 to the proper encoder type (e.g., 0 for none, 1 for ABZ incremental). Input the pulse count in P9-70 (from motor nameplate or measurement). Save and restart for testing.

- Perform Motor Auto-Tuning: Set P9-00 to 1 (static) or 2 (dynamic), then press RUN to start. Parameters update automatically upon completion. The manual cautions: perform tuning without load.

- Adjust Speed Deviation Setpoint: Increase P2-10 (e.g., from 5% to 10%), but avoid excessive values to maintain control accuracy. Test incrementally while monitoring deviations.

- Address Load Issues: Inspect mechanical connections, tighten chains or belts. Reduce load or extend acceleration/deceleration times (P0-13, P0-14). For frequent load surges, consider upgrading VFD power (LC400E-1R5G is 1.5kW with 3.8A output).

- Rectify Wiring: Replace damaged cables, ensure correct U, V, W phase sequence (clockwise rotation). Enhance grounding with resistance <4Ω. After reconnection, conduct no-load trials.

If the fault persists, switch control modes (e.g., from closed-loop to V/F, P0-01=2), as seen in ZHZK cases to bypass feedback issues. Post-resolution, clear fault records (P7-13=1) and monitor operation for at least one hour.

Preventive Measures for Err42 Fault

Prevention is superior to cure. Implement these strategies to minimize Err42 occurrences:

- Standardized Installation and Commissioning: Ensure adequate ventilation during installation and match cable specifications (>1.5mm²). Always perform auto-tuning and parameter backups on first use.

- Routine Maintenance: Quarterly inspect encoders, cables, and loads. Use P7 group to monitor historical faults for early intervention.

- Parameter Optimization: Tailor P2-10 and acceleration/deceleration times to load types. Enable automatic fault reset (P8-14) to reduce manual interventions.

- Environmental Management: Install dust covers and monitor temperatures. Add filters on the power side to mitigate harmonic interference.

- Training and Monitoring: Train operators on manual knowledge. Integrate remote monitoring systems for real-time deviation tracking.

Consistent application of these measures can reduce fault rates to below 5%, extending equipment lifespan.

Real-World Case Studies

Consider a factory fan application: An LC400E-1R5G VFD driving a 1.5kW motor suddenly displayed Err42. Diagnosis revealed P9-70 set to 1024 pulses, but actual was 2048; motor auto-tuning was absent. Solution: Correct parameters, perform dynamic tuning, adjust P2-10 to 8%. Post-restart, normal operation resumed, saving approximately $700 in downtime costs.

Another case from ZHZK: Frequent Err42 in SVC mode was resolved by switching to V/F, highlighting control mode compatibility.

Conclusion

The Err42 fault in ZTV’s LC400E VFD, while common, can be efficiently mitigated through systematic analysis and targeted solutions. Grasping its core—excessive speed deviation—is fundamental. From parameter adjustments to hardware checks, each step demands precision. Looking ahead, advancements in intelligent diagnostics, such as AI monitoring, will further simplify prevention. Users are advised to keep the manual handy and consult manufacturer support regularly. Ultimately, robust maintenance practices ensure reliable equipment performance.