1. Introduction

In the field of modern industrial automation, inverters (Variable Frequency Drives, VFDs) serve as core equipment for motor control and have been widely applied in air compressor systems to achieve energy savings, precise control, and system protection. The Inovance MD500 series inverter is renowned for its high performance, modular design, and rich custom functions, making it particularly suitable for high-power loads such as 315kW air compressors. However, in practical operation, the occurrence of fault codes like Err81 often leads to system shutdowns, affecting production efficiency. Err81 belongs to the user-defined fault category, and its specific triggering mechanism depends on system programming and external signal input. This article deeply analyzes the causes, diagnostic methods, and troubleshooting strategies of the Err81 fault from a technical perspective, and explores optimization paths in the air compressor application scenario. Through structured analysis, it provides practical guidance to help engineers improve system reliability and maintenance efficiency.

As a core equipment for industrial air supply, air compressors have variable frequency control requirements including pressure stability, load matching, and fault protection. The diagnosis of the Err81 fault is not only about fixing the problem but also an opportunity to optimize the entire system. Based on the MD500 series manual, technical practices, and combined with the characteristics of air compressors, this article constructs a complete technical framework to ensure rigorous logic and sufficient data support.

2. Fundamentals of Inverter Technology

Inverters achieve speed regulation by changing the frequency and voltage of the motor’s power supply. Their core principle is based on Pulse Width Modulation (PWM) technology, which converts direct current (DC) into alternating current (AC) with variable frequency. The MD500 series adopts a vector control algorithm, supporting Sensorless Vector Control (SVC) and Voltage/Frequency Control (V/F Control), and is applicable to both asynchronous and synchronous motors.

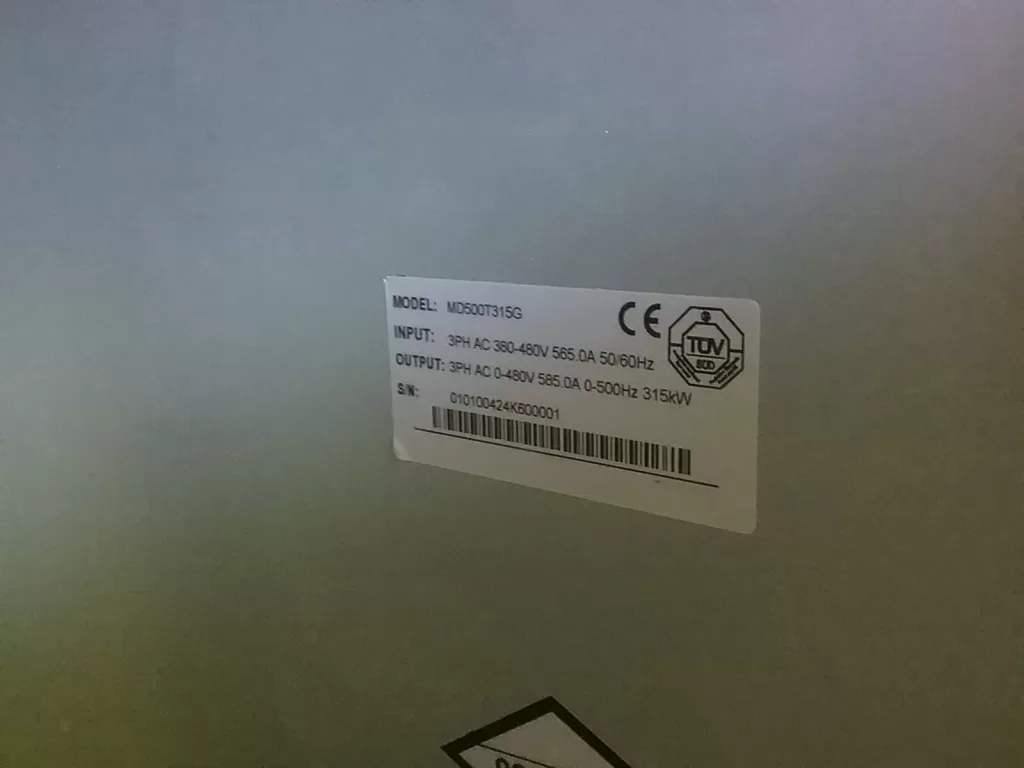

In terms of technical parameters, the MD500T315G model has a three-phase AC input of 380-480V, an output power of 315kW, a current of 585A, and supports a frequency range of 50/60Hz. This series has a built-in PID controller for closed-loop regulation, such as the pressure control of air compressors. The inverter’s fault system is divided into standard faults (Err01-Err79) and user-defined faults (Err80-Err89). The latter allows custom triggering conditions through Digital Inputs (DI), virtual I/O, or expansion cards to achieve specific application protection.

The Electromagnetic Compatibility (EMC) design of the inverter complies with the IEC 61800-3 standard, ensuring anti-interference in industrial environments. The control modes include open-loop and closed-loop, with an overload capacity of 150% rated current for 60 seconds, suitable for the intermittent load of air compressors. Understanding these fundamentals helps analyze Err81: as User-Defined Fault 2, it is usually activated by external logic signals, such as sensor abnormalities or PLC commands.

3. Overview of Air Compressor Systems

Air compressor systems mainly include screw-type, piston-type, and centrifugal-type, among which screw-type compressors most commonly adopt variable frequency control to achieve variable speed operation and energy optimization. System working principle: The motor drives the compressor rotor to compress air to the set pressure, and maintains stability through an unloading valve and a cooling system. After the inverter is involved, the speed can be adjusted according to load requirements, avoiding energy waste from constant-speed operation. Statistics show that variable frequency control can save 20%-40% of electrical energy.

In MD500 applications, the inverter is connected to the motor, pressure sensor, and control PLC. Typical configuration: DI terminals receive pressure switch signals, AI terminals input 4-20mA pressure feedback, and DO terminals output operating status. Most faults of air compressors originate from pressure fluctuations, oil temperature abnormalities, or mechanical wear, which can be mapped to Err81 through user-defined faults. For example, high-pressure protection can be programmed as DI function 45 (User-Defined Fault 2), which is triggered when the pressure exceeds the threshold.

System integration also involves Modbus RTU or Profinet communication to ensure synchronization between the inverter and the upper computer. The dynamic load characteristics of air compressors require the inverter to have fast response, such as the torque boost function (parameter F1-01) of the MD500, which can reach 200% starting torque, suitable for the start-up phase of the compressor.

4. Introduction to Inovance MD500 Series Inverters

The MD500 series is a high-end general-purpose inverter from Inovance, designed for medium and high-voltage loads, supporting a power range of 0.4kW to 500kW. The MD500T315G model is optimized for heavy-duty applications, with a built-in braking unit and DC reactor to reduce harmonic interference. Key features include:

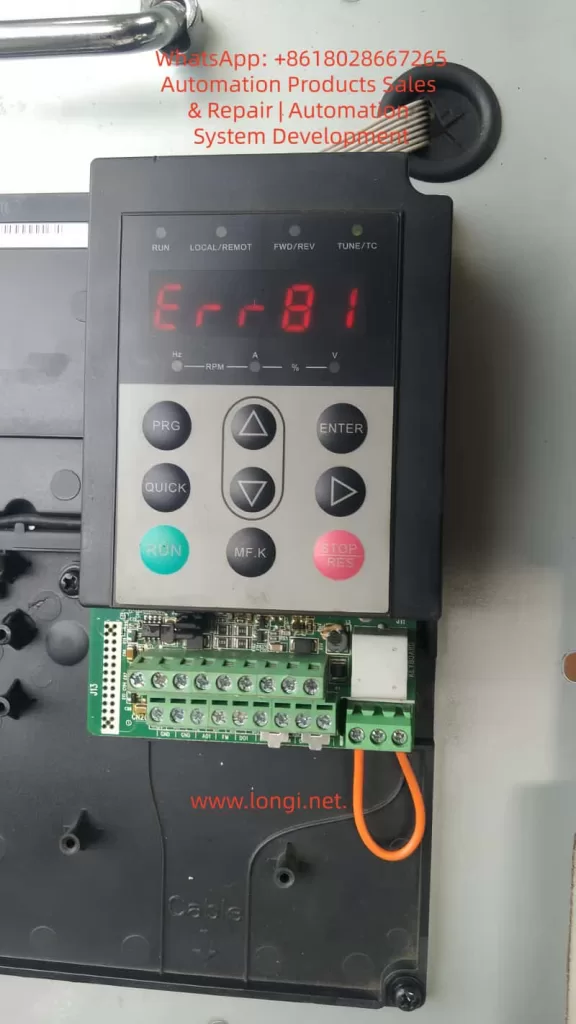

- Modular Structure: The control board and power board are separated for easy maintenance. Green terminal blocks support quick wiring, such as the control interface shown in the photo.

- Parameter Grouping: Group F contains basic parameters, and Group A contains advanced extensions. User-defined faults are configured through Group A7, with A7-00 enabling the programmable card.

- Display and Operation: The LED keypad displays frequency, current, and voltage, supporting PRG/ENTER navigation. The QUICK key provides quick access to commonly used parameters.

- Protection Mechanism: Built-in overcurrent, overvoltage, and undervoltage protection. User-defined faults Err80-Err89 allow expansion of 10 types of protection, with Err81 corresponding to the second user-defined fault.

In air compressors, the MD500 integrates PID regulation (Group F). The pressure setpoint is set through A0-03, and the feedback source is AI1. Communication expansion cards (such as MD38PC1) support custom logic, and Err81 can be triggered by an external PLC to monitor oil level or temperature.

The series manual emphasizes that the diagnosis of user-defined faults such as Err81 requires checking the monitoring parameters in Group U0, such as U0-45 which records the DI status at the time of the fault. This provides a data basis for subsequent analysis.

5. Detailed Explanation of Err81 Fault

Err81 is User-Defined Fault 2 of the MD500 series. The code range Err80-Err89 corresponds to user-defined protection mechanisms. According to the manual, Err81 is not a hardware fault but a software-programmable event. It is usually triggered in the following ways:

- DI Terminal Input: Parameters in Group F4 set DI1-DI10 to function 45 (User-Defined Fault 2). Err81 is triggered when the DI is closed (high level).

- Virtual I/O: Parameters in Group A1 simulate input signals for scenarios without physical connections.

- Expansion Card Logic: Parameter A7-09 sets the fault code to 81, which is activated when the program in the card detects an abnormality.

- Communication Trigger: Write 81 to Modbus address 0x7000 for remote triggering.

Common causes of Err81 in air compressor applications:

- Sensor Abnormality: Faults in the pressure sensor cause abnormal DI signals. For example, when the pressure exceeds 10bar, the high-pressure switch activates the DI.

- Load Mismatch: Under the unloading state of the compressor, excessively low speed causes torque abnormalities, triggering custom logic through PID deviation.

- External Interlock: Safety door opening or emergency stop signals are mapped to Err81 via the PLC.

- Incorrect Parameter Configuration: A7-09 is mistakenly set to 81, or F4-00 functions are repeatedly defined.

When a fault occurs, the inverter stops output, the relay operates, and the keypad displays “Err81”. The manual indicates that the automatic reset of Err81 is controlled by F9-09, with a default of 0 times and a delay of F9-11 seconds.

Compared to Err80 (User-Defined Fault 1), Err81 allows for more granular protection, such as distinguishing between high-pressure and low-temperature faults. This enhances the safety of air compressors but increases diagnostic complexity.

6. Fault Diagnosis Methods

Diagnosing Err81 requires a systematic approach, combining the manual and tools. The steps are as follows:

- Preliminary Observation: Record parameters at the time of the fault. Press PRG to enter U0-62 to confirm code 81, and check U0-45 for current, voltage, and DI status (bit representation, with binary bit 1 indicating activation).

- Historical Record Analysis: F9-14 to F9-44 store recent faults, including timestamps (based on the internal clock). Compare the occurrence patterns of multiple Err81 faults to identify periodic issues such as daily peak loads.

- Parameter Check: Navigate to Group A7 to verify if A7-00 enables the expansion card; check DI functions in Group F4, and if set to 45, track the external signal source. In air compressors, check if F1-00 PID is enabled and the pressure setting in Group A6.

- Physical Inspection: After power-off, check the green terminal connections (as shown in the photo with multiple terminals) and measure the DI voltage with a multimeter (typically 24VDC). Inspect the sensor: compare the pressure gauge reading with the AI feedback; a deviation >5% indicates a fault.

- Simulation Test: Temporarily disable Err81 (set relevant F4 parameters to 0) and operate the compressor for observation. If normal, the problem lies in the custom logic; if the fault persists, check the motor insulation (megohmmeter >5MΩ).

- Advanced Diagnosis: Use Inovance debugging software to connect to the RS485 port and read the complete log. Analyze waveforms: current harmonics >5% indicate power supply issues.

In air compressor scenarios, diagnosis also includes system pressure curves: monitor with a data logger; abnormal speed-pressure relationships indicate the need for PID parameter adjustment (gain F1-02).

7. Fault Troubleshooting Cases

Assume an air compression plant uses the MD500T315G to drive a 315kW screw compressor, experiencing Err81. Diagnostic process:

- Step 1: U0-45 shows DI3 activation, current is normal.

- Step 2: Historical records indicate occurrences every morning, coinciding with pressure peaks.

- Step 3: F4-02=45, DI3 is connected to the high-pressure switch.

Troubleshooting: Replace the switch, clean the filter, and pressure stabilizes. Normal operation resumes after reset.

Another case: Err81 triggered by communication. The PLC writes 81 when monitoring oil temperature >60°C. Troubleshooting: Optimize the cooling fan and adjust the threshold to 65°C.

These cases emphasize that troubleshooting Err81 requires combining mechanical and electrical aspects, with an average repair time of <2 hours.

8. Preventive Measures and Optimization Strategies

The focus of preventing Err81 lies in configuration and maintenance:

- Parameter Optimization: Set F9-09=3 for automatic reset to reduce downtime. Enable PID parameter auto-tuning (F1-28=1).

- Regular Maintenance: Check terminal tightness monthly and calibrate sensors. The replacement cycle of air compressor oil filters is <2000 hours.

- Redundant Design: Add backup DI to avoid single-point failures.

- Software Upgrade: Update the MD500 firmware to support more custom logic.

Optimization strategies: Integrate IoT modules to monitor DI status in real-time and predict Err81 through cloud platforms. Energy-saving optimization: Dynamically adjust speed with a target COP >6.0.

9. Application of Advanced Technologies

In the future, AI algorithms can analyze Err81 logs to predict faults, such as using machine learning models (SVM classification of DI patterns). Blockchain ensures that parameter configurations are tamper-proof. 5G communication enables remote diagnosis, reducing on-site intervention.

In air compressors, digital twin simulation systems can pre-test the impact of Err81.

10. Conclusion

The diagnosis of the Err81 fault reflects the flexibility of the MD500 inverter, which can be efficiently resolved through systematic methods. In air compressor applications, combining mechanical optimization improves overall performance. Continuous technological iteration will further reduce fault rates and promote industrial intelligence.