Table of Contents

- Introduction

- The Role of Inverters in Industrial Automation

- Overview of Hyundai N700E Inverters

- Importance of Overcurrent Faults

- Understanding Overcurrent Faults (E30.4)

- What Is an Overcurrent Fault?

- Meaning of the E30.4 Fault Code

- Overcurrent Protection Mechanisms

- Common Causes of E30.4 Faults

- Overloaded Conditions

- Incorrect Parameter Settings

- Power Supply Issues

- Mechanical Failures

- Internal Inverter Faults

- Diagnostic Steps for E30.4 Faults

- Using the Digital Operator to View Fault Information

- Inspecting the Motor and Load

- Checking Power Supply and Wiring

- Reviewing Inverter Parameters

- Inspecting Inverter Hardware

- Solutions for E30.4 Faults

- Adjusting Acceleration Time

- Optimizing Motor Parameters

- Addressing Power Supply Issues

- Fixing Mechanical Failures

- Repairing or Replacing Inverter Hardware

- Preventive Measures for E30.4 Faults

- Regular Maintenance and Inspections

- Correct Parameter Configuration

- Using High-Quality Power Supplies and Wiring

- Monitoring Load and Environmental Conditions

- Advanced Diagnostics and Tools

- Using Oscilloscopes and Multimeters

- Leveraging Communication Features of N700E Inverters

- Analyzing Fault Logs

- Case Studies

- Case Study 1: Overloaded Condition Causing E30.4 Fault

- Case Study 2: Incorrect Parameter Settings Causing E30.4 Fault

- Case Study 3: Unstable Power Supply Causing E30.4 Fault

- Conclusion and Recommendations

- Summary of E30.4 Fault Diagnosis and Solutions

- Best Practices

- Resources for Further Learning

1. Introduction

1.1 The Role of Inverters in Industrial Automation

Inverters, also known as Variable Frequency Drives (VFDs), are essential components in modern industrial automation systems. They regulate the speed of electric motors by adjusting the frequency and voltage of the power supplied to the motor. This capability enhances energy efficiency, reduces operational costs, and extends the lifespan of equipment. Inverters are widely used in applications such as fans, pumps, conveyors, and machine tools, where precise control of motor speed is critical.

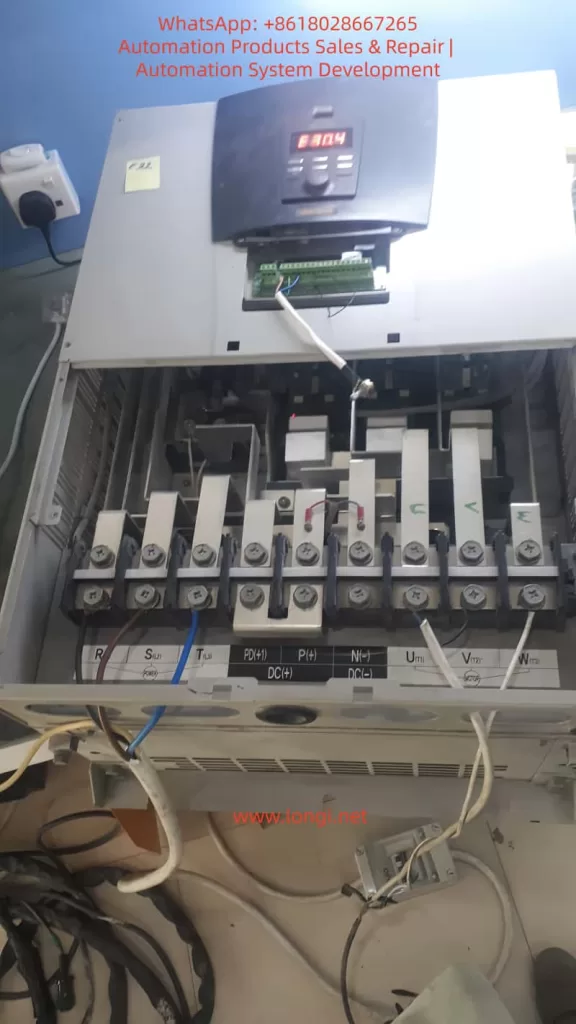

1.2 Overview of Hyundai N700E Inverters

The Hyundai N700E series inverters are high-performance devices designed for industrial applications. Key features include:

- Energy Efficiency: Advanced control algorithms optimize motor performance.

- Versatility: Supports multiple control modes, including V/F control and sensorless vector control.

- Reliability: Built-in protection features such as overcurrent, overload, overvoltage, and undervoltage protection.

- User-Friendly Interface: Equipped with a digital operator for easy parameter configuration and fault diagnosis.

The N700E series is widely used in industrial settings, including fans, pumps, compressors, and other machinery.

1.3 Importance of Overcurrent Faults

Overcurrent faults are among the most common issues encountered in inverter operations. If not addressed promptly, they can lead to equipment damage, production downtime, and safety hazards. Understanding the causes, diagnostic methods, and solutions for overcurrent faults is crucial for maintenance personnel and engineers.

2. Understanding Overcurrent Faults (E30.4)

2.1 What Is an Overcurrent Fault?

An overcurrent fault occurs when the output current of an inverter exceeds its rated value or the set protection limit. This triggers the inverter’s protection mechanism, causing it to shut down to prevent damage. Overcurrent faults can be caused by various factors, including excessive loads, incorrect parameter settings, and power supply issues.

2.2 Meaning of the E30.4 Fault Code

In Hyundai N700E inverters, the E30.4 fault code indicates an overcurrent condition. When this code appears, it means the inverter has detected an output current exceeding the preset protection limit. Immediate action is required to diagnose and resolve the issue.

2.3 Overcurrent Protection Mechanisms

Hyundai N700E inverters are equipped with multiple protection mechanisms to prevent damage from overcurrent conditions:

- Hardware Protection: Current sensors monitor the output current in real-time. If the current exceeds the limit, the inverter cuts off the output.

- Software Protection: Parameters can be adjusted to set the sensitivity and response time of the overcurrent protection.

3. Common Causes of E30.4 Faults

3.1 Overloaded Conditions

- Mechanical Jamming: The motor or mechanical load may be jammed, causing a sudden increase in current.

- Excessive Load: The motor may be operating under an excessive load for an extended period, leading to current levels beyond the inverter’s rating.

3.2 Incorrect Parameter Settings

- Short Acceleration Time: The acceleration time (A02) may be set too short, resulting in high starting currents.

- Incorrect Motor Parameters: The inverter’s motor parameters, such as rated current, power, and pole count, may not match the actual motor specifications.

3.3 Power Supply Issues

- Voltage Instability: The input voltage may fluctuate excessively or be too low.

- Phase Loss or Imbalance: A missing phase or voltage imbalance in the three-phase power supply can cause abnormal current levels.

3.4 Mechanical Failures

- Bearing Damage: Worn or damaged motor bearings can increase friction, leading to higher current draw.

- Transmission System Failures: Issues with belts, gears, or other transmission components can cause mechanical stress and increased current.

3.5 Internal Inverter Faults

- Aging Power Modules: The power modules or capacitors may degrade over time, leading to failures.

- Poor Cooling: Inadequate cooling due to fan failure or dust accumulation can cause overheating and trigger overcurrent protection.

4. Diagnostic Steps for E30.4 Faults

4.1 Using the Digital Operator to View Fault Information

- Access the d13 (Trip event monitor) mode on the digital operator to view the current, frequency, and other data at the time of the fault.

- Check d14-d16 (Trip history) to review past fault records.

4.2 Inspecting the Motor and Load

- Verify that the motor and mechanical load are operating normally, without jamming or abnormal resistance.

- Inspect transmission components (belts, gears, bearings) for damage or obstructions.

4.3 Checking Power Supply and Wiring

- Use a multimeter to measure the input voltage (R, S, T) and ensure it is balanced and within the acceptable range.

- Check for loose or poorly connected wiring terminals.

4.4 Reviewing Inverter Parameters

- Confirm that parameters such as acceleration time (A02) and motor rated current (A06) are correctly set.

- Review overload protection levels (b07) to ensure they are appropriately configured.

4.5 Inspecting Inverter Hardware

- Ensure the cooling fan is operating correctly and the heat sink is free of dust and debris.

- Inspect power modules and capacitors for signs of damage, such as burning, bulging, or leakage.

5. Solutions for E30.4 Faults

5.1 Adjusting Acceleration Time

- Increase the acceleration time (F02) to reduce the starting current.

5.2 Optimizing Motor Parameters

- Ensure the inverter’s motor parameters (rated current, power, pole count) match the actual motor specifications.

5.3 Addressing Power Supply Issues

- Stabilize the input voltage and ensure it is balanced across all three phases.

- Use voltage regulators or filters to improve power quality.

5.4 Fixing Mechanical Failures

- Repair or replace damaged bearings, belts, gears, or other mechanical components.

5.5 Repairing or Replacing Inverter Hardware

- Replace faulty power modules or capacitors.

- Clean the heat sink to ensure proper cooling.

6. Preventive Measures for E30.4 Faults

6.1 Regular Maintenance and Inspections

- Conduct regular inspections of motors and mechanical loads.

- Clean the inverter’s heat sink and cooling fan periodically.

6.2 Correct Parameter Configuration

- Configure inverter parameters accurately based on the motor and load specifications.

6.3 Using High-Quality Power Supplies and Wiring

- Ensure a stable power supply and secure wiring connections.

6.4 Monitoring Load and Environmental Conditions

- Avoid prolonged operation under overloaded conditions.

- Ensure the inverter operates in a suitable environment (temperature, humidity, dust-free).

7. Advanced Diagnostics and Tools

7.1 Using Oscilloscopes and Multimeters

- Use an oscilloscope to monitor current and voltage waveforms for diagnosing power supply and load issues.

- Use a multimeter to measure voltage, current, and resistance.

7.2 Leveraging Communication Features of N700E Inverters

- Utilize the RS485 communication interface to transmit inverter data to a computer for remote monitoring and diagnostics.

7.3 Analyzing Fault Logs

- Analyze the inverter’s fault logs to identify patterns and root causes of faults.

8. Case Studies

8.1 Case Study 1: Overloaded Condition Causing E30.4 Fault

- Problem: A fan frequently experienced E30.4 faults during startup.

- Diagnosis: Inspection revealed a jammed fan impeller.

- Solution: Cleaning the impeller and lubricating the bearings resolved the issue.

8.2 Case Study 2: Incorrect Parameter Settings Causing E30.4 Fault

- Problem: A pump inverter displayed E30.4 faults during startup.

- Diagnosis: The acceleration time (A02) was set too short.

- Solution: Increasing the acceleration time eliminated the fault.

8.3 Case Study 3: Unstable Power Supply Causing E30.4 Fault

- Problem: A conveyor inverter experienced sudden E30.4 faults during operation.

- Diagnosis: The input voltage was found to be highly unstable.

- Solution: Installing a voltage regulator resolved the issue.

9. Conclusion and Recommendations

9.1 Summary of E30.4 Fault Diagnosis and Solutions

E30.4 faults are typically caused by overloaded conditions, incorrect parameter settings, or power supply issues. Systematic diagnostic steps can quickly identify the root cause and implement appropriate solutions.

9.2 Best Practices

- Perform regular maintenance and inspections of inverters and motors.

- Configure inverter parameters accurately.

- Use high-quality power supplies and wiring.

- Monitor load and environmental conditions.

9.3 Resources for Further Learning

- Hyundai N700E Inverter User Manual

- Training courses on inverter maintenance and fault diagnosis

- Professional technical forums and communities

Appendix: Common Fault Code Table

| Fault Code | Fault Type | Possible Causes | Solutions |

|---|---|---|---|

| E30.4 | Overcurrent | Overloaded conditions, incorrect parameters, power supply issues | Adjust parameters, check load, repair power supply |

This article provides a comprehensive guide to diagnosing and resolving E30.4 overcurrent faults in Hyundai N700E inverters. It is designed for engineers and maintenance personnel to better understand and address this common issue.