Introduction

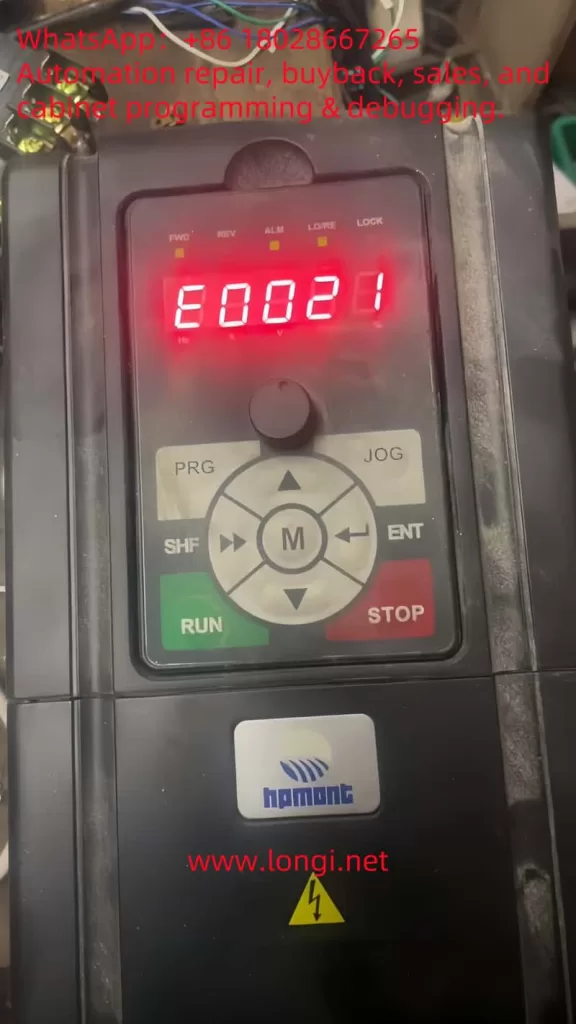

Variable Frequency Drives (VFDs), such as the Hpmont HD20 series, are indispensable in industrial automation, providing precise control over motor speed and torque to enhance efficiency and performance. However, even the most reliable systems can encounter faults that disrupt operations. One such fault, identified by the error code E0021—a “Control Board EEPROM Read/Write Error”—can halt the inverter’s functionality, leading to costly downtime. This article delves into the nature of the E0021 fault, its underlying causes, and offers a detailed, actionable guide to diagnosing and resolving it. Drawing from the HD20 series user manual and fault screenshots, we aim to equip users with the knowledge to restore their inverters efficiently and prevent future occurrences.

What is the E0021 Fault?

The E0021 fault in the Hpmont HD20 series inverter indicates a Control Board EEPROM Read/Write Error. EEPROM, or Electrically Erasable Programmable Read-Only Memory, is a non-volatile memory type integral to the inverter’s control board. It stores essential data, including:

- Configuration Parameters: Settings like motor ratings, control modes, and operational limits.

- User Settings: Custom adjustments made for specific applications.

- Firmware Data: Variables and instructions critical to the inverter’s software operation.

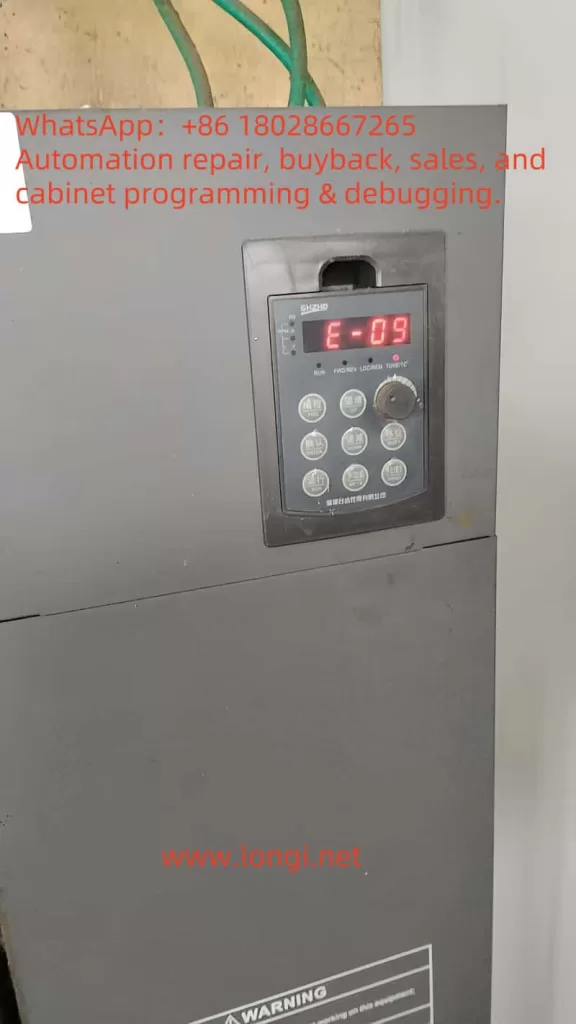

When the inverter displays the E0021 fault, as shown on the control panel with the illuminated “ALM” (alarm) light and the error code in red, it signifies a failure to read from or write to the EEPROM. This disruption can prevent the inverter from loading its operational parameters, resulting in startup failures, erratic behavior, or complete shutdowns. The user manual and fault description (e.g., “控制板EEPROM读写故障” or “Control Board EEPROM Read/Write Fault”) highlight this as a critical issue requiring immediate attention.

The Nature and Essence of the E0021 Fault

At its core, the E0021 fault reflects a breakdown in the inverter’s ability to manage its stored data. The EEPROM’s role is to ensure that the inverter retains its settings across power cycles, making it a cornerstone of reliable operation. A read/write error could stem from:

- Data Access Failure: The control board cannot retrieve stored parameters.

- Data Modification Failure: New settings or updates cannot be saved.

- Data Integrity Issues: Corrupted data renders the EEPROM unreadable or unusable.

This fault’s essence lies in its potential to compromise the inverter’s functionality entirely. Without access to its configuration, the HD20 series inverter cannot control the connected motor effectively, impacting production lines and industrial processes.

Potential Causes of the E0021 Fault

Understanding the root causes of the E0021 fault is crucial for effective troubleshooting. Based on the fault description and general VFD principles, the following factors may contribute:

- Power Supply Instability

Voltage fluctuations, surges, or sudden power losses can interrupt EEPROM operations. The HD20 series manual (Page 16) specifies a rated voltage (e.g., “额定电压”), and deviations from this range can affect data integrity. - EEPROM Hardware Failure

The EEPROM chip may degrade over time due to its finite write cycles (typically 100,000–1,000,000) or suffer damage from electrical stress, heat, or manufacturing defects. - Data Corruption

Electrical noise, improper shutdowns, or electromagnetic interference (EMI) in industrial environments can corrupt the EEPROM’s data, making it inaccessible. - Firmware Issues

Bugs or corruption in the inverter’s firmware, which manages EEPROM interactions, can lead to read/write errors. An incomplete firmware update could exacerbate this. - Environmental Factors

The manual (Page 20, “第三条 机械安装”) advises on installation conditions. Excessive heat, humidity, or dust can degrade the EEPROM and control board. - Control Board Malfunction

Damage to other components, such as solder joints or circuits interfacing with the EEPROM, can disrupt communication.

Diagnosing the E0021 Fault

Accurate diagnosis is the first step to resolution. Follow these steps to identify the cause:

- Observe Symptoms

- Check the control panel (as per the screenshot) for the E0021 code and “ALM” light.

- Note if the inverter fails to start, loses settings, or shows additional faults.

- Verify Power Supply

- Measure input voltage with a multimeter to ensure it aligns with the manual’s specifications (e.g., 380V ±15%).

- Look for fluctuations or noise using an oscilloscope if available.

- Inspect the Environment

- Ensure compliance with installation guidelines (Page 20), checking for proper ventilation, temperature (e.g., 0°C–40°C), and EMI sources.

- Power Cycle the Inverter

- Turn off the inverter, wait 5 minutes, and restart it to rule out temporary glitches.

- Check Firmware and Fault Logs

- Access the fault history via the control panel (“PRG” and “ENT” buttons) to identify patterns.

- Verify the firmware version against Hpmont’s latest release.

- Examine the Control Board

- Power down safely and inspect for visible damage (e.g., burnt components, loose connections) around the EEPROM chip (often labeled “24Cxx” or “25Cxx”).

Resolving the E0021 Fault

Once diagnosed, apply these solutions tailored to the cause:

- Stabilize Power Supply

- Install a surge protector or UPS to mitigate voltage issues.

- Ensure proper grounding to reduce EMI.

- Reset to Factory Settings

- Use the control panel to reset parameters (refer to the manual for exact steps, typically via “PRG” and a reset code).

- Reprogram settings post-reset, using backups if available.

- Update Firmware

- Download the latest firmware from Hpmont’s website and follow update instructions, ensuring an uninterrupted process.

- Replace the EEPROM or Control Board

- If the EEPROM is faulty, a technician can desolder and replace it with an identical chip, reprogramming it with default or backed-up data.

- For broader control board issues, replace the entire board (e.g., compatible with HD20-4T5PSG), then reset and reconfigure.

- Address Environmental Issues

- Enhance cooling, reduce humidity, or shield the inverter from interference sources.

Preventive Measures

To avoid future E0021 faults:

- Maintain Power Quality: Use stabilizers and avoid frequent power interruptions.

- Limit EEPROM Writes: Minimize unnecessary parameter changes.

- Optimize Environment: Adhere to manual guidelines for temperature and humidity.

- Regular Maintenance: Inspect and clean the inverter periodically.

- Backup Parameters: Save settings regularly if the HD20 supports it.

Conclusion

The E0021 fault—Control Board EEPROM Read/Write Error—in the Hpmont HD20 series inverter is a significant challenge that can disrupt industrial operations. By understanding its nature as a data access failure, identifying causes like power instability or hardware issues, and applying systematic diagnosis and resolution steps, users can restore functionality efficiently. Preventive measures further ensure long-term reliability. For persistent issues, Hpmont’s technical support can provide expert assistance, leveraging the manual’s guidance and replacement parts. This comprehensive approach minimizes downtime and sustains the HD20 series’ performance in demanding applications.