The Allen-Bradley PowerFlex 400 series of inverters are widely used in the Heating, Ventilation, and Air Conditioning (HVAC) industry, especially in a large number of fan and pump applications. Therefore, accumulating repair techniques and experience in fault location is of great importance. After continuous operation for many years, issues such as aging of internal fans and low-voltage capacitors, and increased power supply ripple in the inverter can easily lead to control failures. Among them, fan faults and drive power supply aging are high-frequency fault points. This article systematically discusses a real-world case where a PowerFlex 400 inverter displayed the FAULT 032: Fan Feedback Loss, covering multiple aspects.

I. Fault Background and Initial Assessment

An Allen-Bradley PowerFlex 400 inverter sent in for repair by a customer failed to operate after power-on self-test, with the keypad display showing the alarm:

FAULT 032

Fan Fdbck Loss

This alarm indicates that the main board has detected that the fan control output has been activated, but the feedback signal has not been received or the signal form is non-compliant. The fans in PowerFlex 400 are mostly of three-wire or four-wire design. In addition to power supply, they also provide a Tach/FG feedback signal (generally in the form of an open-collector pulse output). The inverter determines the fan speed by sampling the pulse frequency. If the Microcontroller Unit (MCU) does not detect feedback changes within a set time, fault 032 is triggered. On-site inspection revealed that the fan was damaged, with severe shaft seizure and no signal output from the speed feedback, clearly identifying the cause of the fault.

II. Fan Repair and Extended Issues

After replacing or repairing the fan, the inverter passed the power-on self-test. However, the repair engineer noticed that the thermal grease in the temperature control area of the control board was aged and the tops of the capacitors were bulging, prompting a further in-depth inspection. The PowerFlex 400 adopts a zoned power supply structure. Long-term operation with a fan fault can lead to an increase in the temperature of the control board, causing an increase in the Equivalent Series Resistance (ESR) of the capacitors in the low-voltage power supply circuit and deterioration of ripple, resulting in drive voltage drift. Therefore, although the fan alarm has been eliminated, potential power supply degradation risks need to be investigated. Otherwise, the inverter may fail again during high-load or long-term operation, or even damage the IGBT drive unit.

III. Analysis of the Circuit Structure in the Low-Voltage Power Supply Drive Area

The control board of the PowerFlex 400 generally has the following low-voltage power supplies:

| Voltage Level | Typical Function |

|---|---|

| 5V DC | MCU, communication, logic sampling |

| 9 – 12V DC | Front-stage drive buffering, fan drive, and detection-related circuits |

| 15 – 18V DC | IGBT drive, optocoupler bias power supply |

| 24V DC | Relays, solenoid valves, external IO power supply |

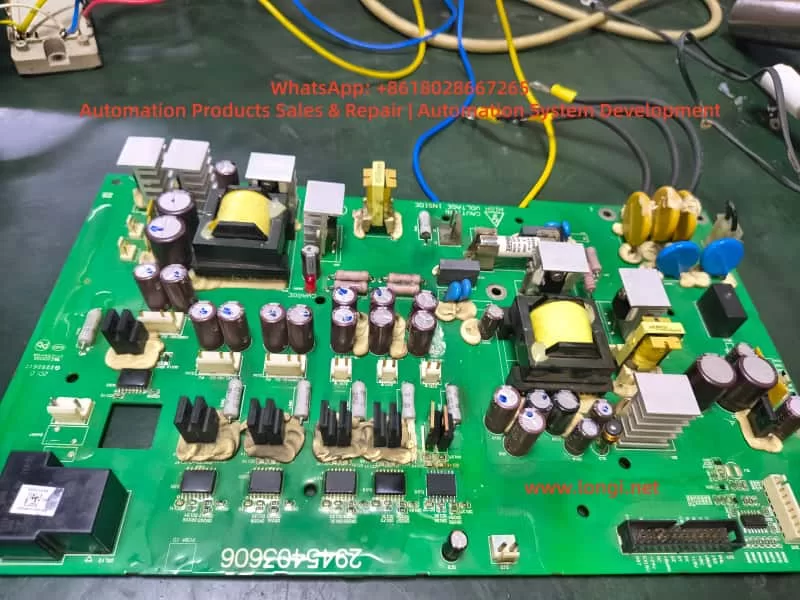

When repairing, the engineer removed the drive board and marked two key voltage areas:

- The area marked with a pink circle on the left measured 9.5V DC.

- The area marked with a red circle in the middle measured 19V DC.

Whether these two voltages are reasonable and within the normal operating range needs to be comprehensively judged from the perspectives of voltage regulation structure, load conditions, and capacitor health status.

IV. Technical Analysis of Test Data

1. Analysis of the 9.5V DC Measurement Result

This area is adjacent to multiple small filter capacitors, Schottky rectifiers, and three-terminal voltage regulators, and belongs to the low-voltage DC voltage regulation output area. Under normal circumstances, it may be:

- A 9V or 10V regulated output (corresponding to 9.5V, which is within the normal tolerance range).

- It may also be designed for a target of 12V, but the voltage has dropped to 9.5V due to capacitor aging.

The determination methods are as follows:

| Test Method | Determination Basis |

|---|---|

| Measure 9.5V with no load and a significant voltage drop under load | Indicates an increase in capacitor ESR or weakened voltage regulation |

| Ripple on the oscilloscope > 100mV | Indicates capacitor degradation and the need for replacement |

| Insufficient fan speed and irregular feedback waveform after loading the fan | Indicates insufficient power supply capacity |

If the original design was for 12V, the inverter may intermittently alarm and have unstable drive under heavy load conditions, and it cannot be directly considered that 9.5V is completely normal.

Conclusion: 9.5V is acceptable, but its health status needs to be further confirmed by combining ripple and load voltage drop measurements. It is recommended to replace all the capacitors in this area.

2. Analysis of the 19V DC Measurement Result

The presence of 19V in the drive power supply area is worthy of attention. The common voltages on the drive side of PowerFlex are:

- 15V, 16V, and 18V are the most common.

- A voltage exceeding 19V is close to the voltage tolerance boundary of the components. If it continues to rise, it may break down the drive optocoupler or gate resistor.

If the voltage regulation target here is 18V, then 19V is on the high side. Possible reasons include: - Parameter drift of the voltage regulation diode.

- Aging of the filter capacitor, causing the power supply peak to rise.

- Failure of the feedback sampling resistor.

Voltage spikes under no-load conditions are common, but the voltage should drop under load.

The following tests must be carried out: - Whether the voltage drops to 17 ± 1V under load.

- Whether there are spikes in the waveform.

- Whether the temperature of the voltage regulation chip is abnormal.

Conclusion: Although the inverter may not directly report an error when operating at 19V, there are potential risks for long-term operation. The voltage regulation chain should be thoroughly investigated, and aging capacitors should be replaced.

V. Systematic Repair Recommendation Process

To ensure long-term repair reliability, it is recommended to follow the following sequence for step-by-step handling:

Step 1: Fan Feedback Verification (Core of Fault 032)

| Item | Confirmation Method |

|---|---|

| Whether the fan power supply is stable | Measure the fan VCC voltage |

| Whether the feedback signal exists | Detect the FG/TACH waveform with an oscilloscope |

| Whether the MCU sampling end is unobstructed | Confirm the channel resistance, capacitors, and pull-up resistors |

If the pulse frequency is normal, fault 032 will not recur.

Step 2: In-Depth Detection of the Low-Voltage Power Supply

Measure 9.5V and 19V under no-load, fan load, and whole-machine operation conditions respectively.

Observe the voltage drop and fluctuation range.

If the tops of the capacitors are bulging, it is recommended to replace all the capacitors in the area (the capacitor aging situation on this board is obvious).

Empirical judgment: For PowerFlex inverters that have been in operation for many years, 70% of the faults are related to capacitors. Replacing all the capacitors at once is more cost-effective and reliable than testing each capacitor individually.

Step 3: Health Assessment of the Drive Circuit

- Check whether the IGBT drive optocouplers are aged.

- Test whether the rising and falling edges of the gate waveform are symmetrical.

- If the voltage drop capability of 19V is poor, replace the voltage regulation diode and filter capacitors.

Step 4: Reassembly and Load Run Test

Run the inverter for at least half an hour to verify:

- Whether the fan feedback alarm recurs.

- Whether the drive temperature rise is normal.

- Whether there are output waveform glitches or abnormal noises.

Only after passing the test can the inverter be delivered for use.

VI. Technical Summary and Experience Extraction

- Fault 032 is mostly caused by fan damage or loss of feedback signal. Repairing the fan or restoring the feedback signal path can eliminate the alarm.

- Fan faults are often accompanied by an increase in the temperature rise of the control board. After the fan stops rotating, the internal temperature increases, accelerating capacitor aging, and power supply voltage drift may follow.

- Although 9.5V and 19V can operate, the voltage regulation target values need to be evaluated. In particular, a high voltage in the drive area may affect component lifespan, and the ripple and load performance should be tested.

- Preventive replacement of capacitors is a key operation to improve repair success rate and reliability. Batch replacement of capacitors on the PowerFlex control board helps ensure long-term stable operation.

- Repairs must proceed step by step from fan feedback → low-voltage power supply → drive chain → whole-machine baking and run test to avoid only addressing surface faults while ignoring the root cause and forming rework.

Conclusion

This article is based on a real repair case of a PowerFlex 400 inverter with a fan feedback alarm and abnormal drive power supply voltage. Through voltage test judgment logic, voltage regulation circuit analysis, acceptable operating range determination, and fault extension explanations, it provides a complete set of repair methods that can be directly referenced from both theoretical and practical perspectives. It is hoped that this article can provide clear directions for more electrical repair engineers when dealing with similar inverter faults, improve diagnostic efficiency, reduce the number of disassemblies and assemblies, and achieve the goal of successful first-time repairs.