I. Introduction

The JEOL JSM-IT200 series scanning electron microscope (SEM) is a high-performance analytical instrument specifically designed for scientific research and metrology applications. This series features high resolution (below 10 nm), supports both high-vacuum and low-vacuum mode imaging, and offers X-ray energy-dispersive spectroscopy (EDS) for elemental analysis. This user guide aims to assist users in comprehensively mastering the use of the JSM-IT200 series, from safety preparations to advanced operations, ensuring efficient utilization of the instrument.

II. Safety Guidelines

Training and Protection

All users must complete Environmental, Health, and Safety (EH&S) training and wear personal protective equipment (PPE) such as safety glasses and rubber gloves.

Sample Preparation

Avoid using solvents in the SEM chamber to prevent volatile organic compound (VOC) contamination; handle plastic sharp objects properly; links to Material Safety Data Sheets (MSDS), EH&S laboratory safety manuals, and CIF safety manuals are available on the computer desktop.

Instrument Operation

Record any abnormal responses or error states, capture images using the screenshot tool, and notify relevant personnel; promptly report filament failures and replace the Wehnelt cap and spare filaments.

Vacuum System

Wear gloves when exchanging samples and keep the sample holder clean; firmly secure powder samples to prevent damage to the electron gun.

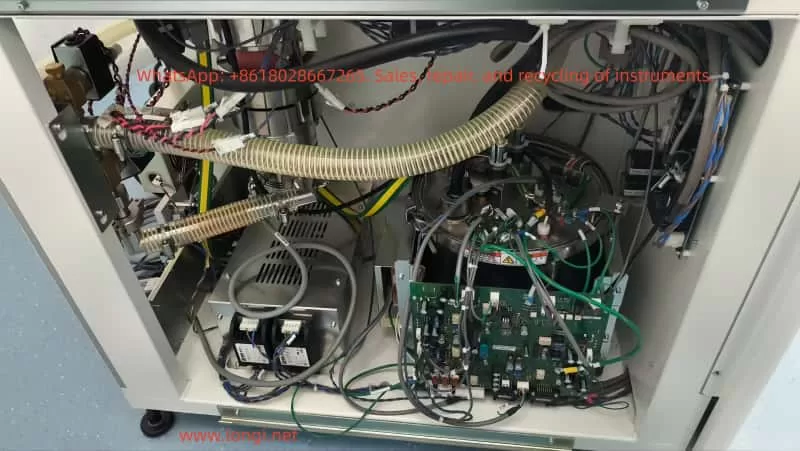

III. System Overview

The JSM-IT200 series consists of an electron optical column (EOS), a sample chamber, a vacuum system, and control software. In terms of software, log in to the instrument computer as the.\cif user and manage logins/logouts using the LockScreen program; the OperationServer icon on the taskbar is a critical background process for SEM operation; the bottom of the desktop contains main programs such as SEM Operation and SMILE VIEW Lab.

IV. Sample Preparation and Loading

Sample Preparation

Samples must be firmly fixed and have moderate conductivity; non-conductive samples require gold coating; powder samples must not be loosely loaded.

Sample Holder

Various types of holders are provided; measure the sample height to prevent collisions.

Loading Process

Follow the guidance of Specimen Exchange Navi, including venting, opening the chamber, entering sample information, setting parameters, adjusting the Z-axis height, closing the chamber door, evacuating the chamber, and starting the electron gun.

V. Software Interface and Operation

Main Interface

Displays real-time images, with the control bar below including zoom, focus, etc.; stage navigation is located in the upper right corner, and the chamber camera helps tilt samples.

Control Options

Include screen buttons and MUI knobs; the mouse wheel controls zooming; in manual mode, adjust focus and astigmatism; automatic astigmatism correction simplifies operations.

Display Histogram

Optimize brightness/contrast settings to ensure no signal clipping.

Advanced Navigation

For example, Holder Graphics displays the current sample position, and the SNS option switches to CCD color images.

VI. Imaging Techniques

Imaging Modes

Include secondary electron images (SEI) and backscattered electron images (BSE), highlighting surface topography and compositional differences, respectively.

Parameter Optimization

Adjust the accelerating voltage, probe current, and magnification according to sample requirements.

Automatic Functions

One-click adjustment of focus, contrast, brightness, and astigmatism; use BED and LSED to obtain images in low-vacuum mode.

Advanced Functions

Such as the Montage function for automated large-area observation and 3D imaging options for creating stereo images and 3D models.

VII. Elemental Analysis (EDS)

Operation

Specify points/lines/areas on the SEM screen for EDS analysis, displaying X-ray spectra and major elements in real time.

Analysis Methods

Include qualitative analysis, quantitative analysis, line analysis, and elemental mapping.

Advanced Functions

Such as QBase database comparison of spectra, PlayBack Analysis for replaying accumulated frames, and GSR analysis for automated classification of gunshot residue particles.

VIII. Data Management and Reporting

Data Management

SMILE VIEW Lab integrates the management of CCD, SEM images, and EDS data, supporting search and position display.

Report Generation

Select data to automatically layout reports, support the creation of templates and one-click updates; output to Word or PowerPoint for easy sharing.

IX. Maintenance and Troubleshooting

Maintenance

Pre-align the filament; gun alignment is fully automatic; when replacing the filament, insert the Wehnelt to automatically center it.

Troubleshooting

Record error states and take screenshots; promptly report filament failures and replace them; follow the procedure when ending a session.

X. Advanced Functions

Zeromag

Seamlessly transition from optical to SEM, supporting multi-analysis position presets and reviews.

Particle Analysis Software

Automatic/manual particle detection, EDS analysis, classification, and statistical graphs.

Language Switching

The UI supports Japanese/English; the vacuum system is fully automatic.

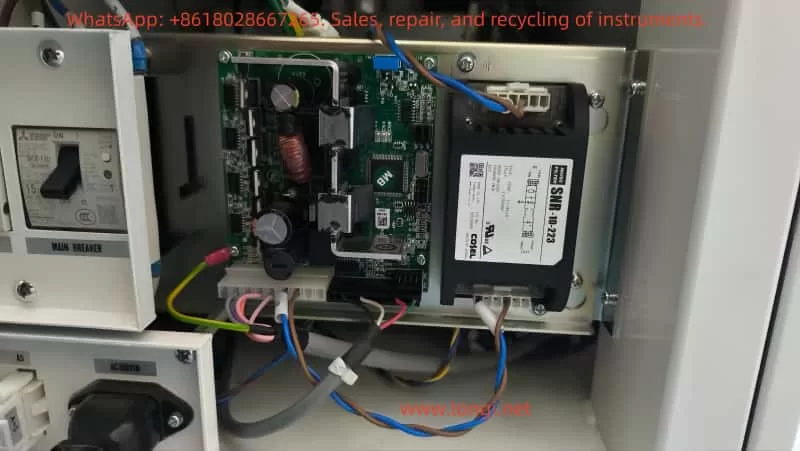

Installation Requirements

Specify power supply, room temperature, humidity, and space requirements.

XI. Conclusion

The JSM-IT200 series simplifies SEM operations and enhances analytical efficiency through integrated software and automatic functions. This guide covers comprehensive steps from safety to advanced applications, and users can apply them according to their specific configurations. Practice is key; by analyzing poor images, optimizing parameters, and utilizing tools such as histograms and automatic corrections, users can ensure instrument reliability and data accuracy, driving innovation in fields such as materials science and biology.