I. Instrument Overview and Basic Operations

1.1 Instrument Introduction

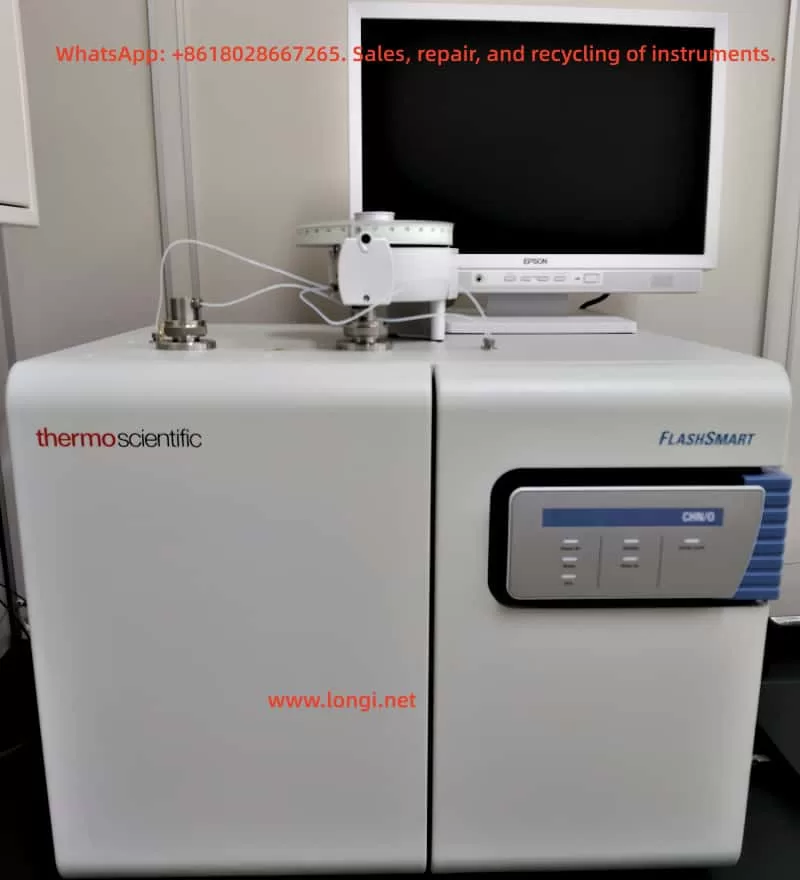

The Thermo Fisher FlashSmart Elemental Analyzer is a fully automated organic elemental analysis system that employs the dynamic combustion method (modified Dumas method) to determine nitrogen, carbon, hydrogen, and sulfur content. It measures oxygen content through high-temperature pyrolysis. This instrument can be configured with a single-channel or dual independent-channel system, and the MultiValve Control (MVC) module enables automatic dual-channel switching for analysis.

Main Technical Parameters:

- Detector Type: Thermal Conductivity Detector (TCD)

- Power Supply: 230V ± 10%, 50/60Hz, 1400VA

- Dimensions: 50cm (height) × 59cm (width) × 58cm (depth)

- Weight: 65kg

- Maximum Operating Temperature: 1100℃

- Gas Requirements: High-purity helium (carrier gas), oxygen (combustion aid), argon (for specific configurations)

1.2 Safety Precautions

Hazardous Operation Warnings:

- High Voltage Risk: The instrument contains high-voltage components. Non-professionals are prohibited from opening the electrical compartment.

- High-Temperature Surfaces: The furnace can reach temperatures up to 1100℃. Avoid contact during operation.

- Gas Safety: Hydrogen use requires extreme caution, as concentrations as low as 4% pose an explosion risk.

- Chemical Hazards: Wear protective gear when handling reaction tube packing materials and sample ashes.

Personal Protective Equipment (PPE) Requirements:

- Eye Protection: Splash-resistant goggles

- Hand Protection: White nitrile gloves (for chemicals)/heat-resistant gloves (for high-temperature operations)

- Respiratory Protection: Dust masks

- Body Protection: Lab coats + plastic aprons

1.3 Startup Preparation Procedure

Gas Connection:

- Helium Inlet Pressure: 2.5bar (36psig)

- Oxygen Inlet Pressure: 2.5-3bar (36-44psig)

- Argon Inlet Pressure: 2.5bar (N/Protein configuration) or 4-4.5bar (NC Soils configuration)

- Leak Testing: Perform on all gas lines.

Power Connection:

- Confirm voltage stability at 230V ± 10%.

- Ensure proper grounding; avoid sharing circuits with large motor equipment.

Software Installation:

- System Requirements: Windows 7/8/10, at least 1GB hard drive space.

- Install EagerSmart data processing software and drivers.

II. Calibration and Adjustment Procedures

2.1 Initial Setup

Hardware Configuration Steps:

- Select Reaction Tube Configuration Based on Analysis Needs:

- CHN Mode: Quartz reaction tube + chromium oxide/reduced copper/cobalt oxide packing.

- CHNS Mode: Quartz reaction tube + copper oxide/electrolytic copper packing.

- O Mode: Quartz reaction tube + nickel-plated carbon/quartz shavings packing.

- N Mode: Dual reaction tubes in series + Plexiglas adsorption filter.

- Install Autosampler:

- MAS Plus Solid Autosampler: Up to 125-position sample tray.

- AI 1310/AS 1310 Liquid Autosamplers: 8-position or 105-position sample trays.

- Connect MVC Module (Dual-Channel Configuration):

- Remove bypass panel from the rear.

- Connect gas lines for left and right channels.

- Configure dual MAS Plus autosamplers.

2.2 System Calibration

Three-Step Calibration Method:

- Leak Testing:

- Initiate automatic leak detection via software.

- Acceptable Leak Rate: <0.1mL/min.

- Use soapy water to locate leaks if detected.

- Signal Baseline Adjustment:

- Set TCD detector temperature constant (typically 40-120℃).

- Adjust bridge voltage to 5V.

- Baseline Drift: Should be <0.1mV/10min.

- Standard Curve Establishment:

- Use high-purity standards like acetanilide (nitrogen 16.09%, carbon 71.09%, hydrogen 6.70%).

- Minimum Concentration Gradients: 5 points (recommended range: 0.1-5mg).

- Correlation Coefficient (R²): Should be >0.999.

Calibration Frequency Recommendations:

- Daily Use: Calibrate after each startup.

- Continuous Analysis: Verify calibration every 50 samples.

- After Consumable Replacement: Recalibration is mandatory.

2.3 Method Optimization

Parameter Adjustment Guidelines:

- Oxygen Injection Time:

- Regular Samples: 4-6 seconds.

- Refractory Samples: Extend to 8 seconds.

- High-Sulfur Samples: Add vanadium pentoxide as a combustion aid.

- Furnace Temperature Settings:

- Combustion Furnace: 950-1100℃.

- Reduction Furnace: 840℃.

- Pyrolysis Furnace (O Mode): 1060℃.

- Carrier Gas Flow Rate:

- Helium: 100-140mL/min.

- Reference Gas: 30-50mL/min.

III. Routine Maintenance

3.1 Regular Maintenance Schedule

Maintenance Schedule Table:

| Maintenance Item | Frequency | Key Operation Points |

|---|---|---|

| Reaction Tube Regeneration | Every 200 analyses | Empty packing material, incinerate at 550℃ for 2 hours. |

| Adsorbent Replacement | Monthly | Activate molecular sieve at 300℃, replace desiccant (silica gel) promptly. |

| Autosampler Cleaning | Weekly | Ultrasonically clean tin/silver cups, inspect piston seals. |

| Chromatographic Column Aging | Quarterly | Age at 280℃ with carrier gas for 8 hours. |

| Comprehensive System Verification | Annually | Conducted by a professional engineer. |

3.2 Key Component Maintenance

Reaction Tube Packing Guidelines:

- Quartz Reaction Tubes:

- Begin packing from the conical end.

- Compact each layer with a dedicated tamping rod.

- Separate layers with quartz wool.

- Maintain total packing height at 80% of tube length.

- HPAR Alloy Steel Reaction Tubes:

- Must be used with crucibles.

- Ensure uniform distribution of oxidation catalysts.

- Use dedicated tools for installation/removal.

Adsorption Filter Maintenance:

- Large (Plexiglas) Filters:

- Packing sequence: Quartz wool → soda lime → molecular sieve → silica gel.

- Pre-moisten soda lime with 0.5mL water.

- Small (Pyrex) Filters:

- Used in CHNS/O modes.

- Packing: Quartz wool → anhydrous magnesium perchlorate.

3.3 Consumable Replacement Intervals

Recommended Replacement Intervals:

- Quartz Wool: Replace when changing reaction tube packing.

- Reduced Copper: Every 500 analyses.

- Oxidation Catalyst: Every 300 analyses.

- Nickel-Plated Carbon (O Mode): Every 150 analyses.

- TCD Filament: Replace when baseline noise occurs.

- Sealing O-Rings: Replace if leaks are detected or every 6 months.

IV. Troubleshooting and Solutions

4.1 Common Error Codes

Error Code Table:

| Code | Meaning | Solution |

|---|---|---|

| E01 | Left Furnace Temperature Exceeded | Check thermocouple connection, restart system. |

| E04 | TCD Signal Overflow | Adjust gain, verify carrier gas purity. |

| E12 | Safety Cutoff Triggered | Check cooling fan, allow system to cool. |

| E25 | EFC-t Module Flow Abnormality | Check for gas line blockages, clean filter. |

| E33 | Autosampler Communication Failure | Reconnect cables, verify port settings. |

4.2 Typical Problem Resolution

Analysis Result Anomaly Investigation:

- Low Nitrogen Results:

- Check if reduced copper is失效 (discolored black).

- Verify adequate oxygen injection.

- Confirm complete sample combustion (observe flame).

- Sulfur Peak Tailings:

- Replace copper oxide packing layer.

- Add vanadium pentoxide combustion aid.

- Check chromatographic column connections for leaks.

- Unstable Oxygen Results:

- Verify nickel-plated carbon packing height (should be 60mm).

- Confirm silver cup seal integrity.

- Validate pyrolysis furnace temperature stability (±2℃).

Hardware Fault Handling:

- Furnace Temperature Failure to Rise:

- Check SSR solid-state relay status.

- Measure transformer output voltage (should be 48V AC).

- Confirm fuse integrity (AC 1112 board F1/F2).

- Abnormal Gas Flow:

- Clean EFC-t module filter.

- Verify solenoid valve EV1-EV4 operation.

- Calibrate flow sensors S1/S2.

- TCD Baseline Drift:

- Extend equilibration time to 2 hours.

- Verify reference gas flow stability.

- Replace aged filament.

4.3 Emergency Response Procedures

Safety Emergency Plan:

- Gas Leak:

- Immediately close cylinder main valve.

- Activate laboratory ventilation system.

- Avoid operating electrical equipment.

- Furnace Overheating:

- Trigger front panel emergency stop button.

- Cut off main power supply.

- Purge system with inert gas.

- Abnormal Combustion:

- Maintain system enclosure.

- Direct exhaust through fume hood.

- Do not cool directly with water.

V. Advanced Application Techniques

5.1 Special Sample Handling

Solutions for Challenging Samples:

- High Inorganic Salt Samples:

- Use quartz crucibles to prevent corrosion.

- Reduce quartz wool between packing layers.

- Increase oxygen injection pressure by 10%.

- Volatile Liquids:

- Utilize AI 1310 liquid autosampler.

- Adsorb sample onto diatomaceous earth.

- Preheat injection needle to 40℃.

- Viscous Samples:

- Grind with quartz sand for homogenization.

- Use specially shaped tin cups.

- Extend combustion time by 20%.

5.2 Data Quality Enhancement

Best Practice Recommendations:

- Sample Preparation:

- Homogenize to below 80 mesh.

- Pre-dry samples with >5% moisture content.

- Avoid fluorine-containing containers.

- Weighing Techniques:

- Use blank tin cups for calibration with microsamples (<1mg).

- Employ “sandwich” loading method for highly volatile samples.

- Utilize a 0.1μg precision balance.

- Quality Control:

- Insert standard samples every 10 analyses.

- Maintain parallel sample deviation <1.5%.

- Retain all original chromatograms.

5.3 Automation Features

Intelligent Function Applications:

- Standby Mode:

- Reduce carrier gas to 10mL/min.

- Maintain furnace temperature at 50% of setpoint.

- Auto-wake via timer function.

- Sequence Analysis:

- Supports 125-sample unattended operation.

- Enables alternating method runs.

- Auto-generates comprehensive reports.

- Remote Monitoring:

- View system status remotely via EagerSmart software.

- Set up email alerts.

- Auto-backup data to network.

VI. Appendices and Support

6.1 Technical Specifications Summary

Key Parameter Quick Reference Table:

- Detection Limits: N/C/H 0.01%, S/O 0.02%

- Precision: RSD <0.5% (for conventional elements)

- Analysis Time: CHN 5min, O 4min, CHNS 6min

- Sample Size: 0.01-100mg (solid), 0.1-10μL (liquid)

- Gas Consumption: Approximately 10L helium per sample

6.2 Regulatory Compliance

Certifications and Compliance:

- CE Certification: Complies with EN 61010-1 safety standards.

- RoHS: Complies with Directive 2011/65/EU.

- WEEE: Classification number 23103000.

- GLP/GMP Compliance: Meets regulatory requirements.

This guide is based on the FlashSmart Elemental Analyzer Operating Manual (P/N 31707001, Revision E) and covers key points for the instrument’s operational lifecycle. Always adapt usage to specific configurations and application needs while strictly adhering to local safety regulations.