1. Introduction

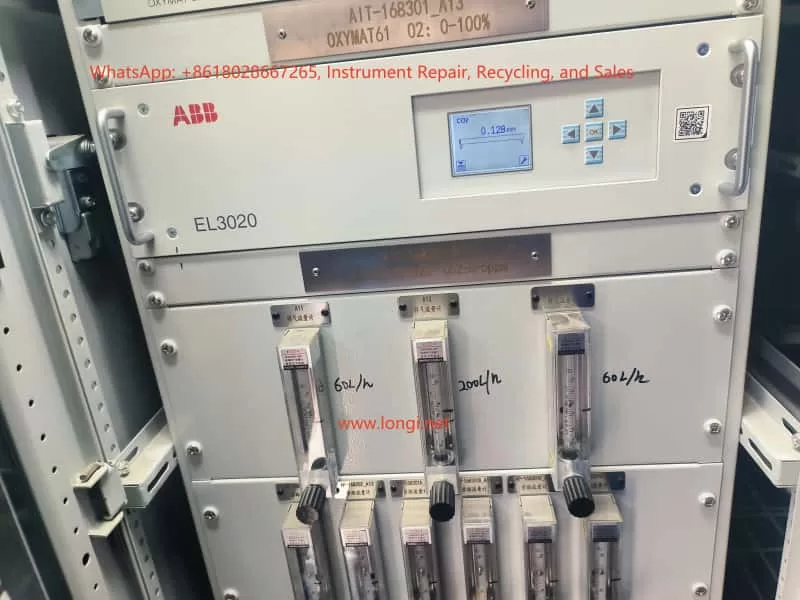

The ABB EL3020 (equipped with the Uras26 infrared module) is a high-precision, multi-component gas analyzer widely used in chemical, metallurgy, power, and environmental sectors for continuous CO₂, CO, CH₄, and other gas measurements.

To ensure measurement accuracy and long-term stability, Zero Point Calibration and Span Calibration must be performed regularly. However, during field calibration, engineers often encounter “Calibration Rejected,” “Half Span Shift,” or complete lockout after a failed attempt, preventing further calibration and impacting operation.

This article explains the calibration principle, common causes of failure, error phenomena, troubleshooting steps, and recovery methods. It is based on real field cases, providing engineers with actionable, field-ready solutions.

2. Calibration Principles of the EL3020 (Uras26)

2.1 Zero Point Calibration

The purpose of zero point calibration is to eliminate background interference signals from the optical system and sensors when no target gas is present, aligning the measurement curve to zero.

- Condition: Introduce zero gas without the target component (e.g., high-purity nitrogen or zero air).

- Requirement: Gas purity must be adequate (CO₂ < 0.1 ppm for a 0–5 ppm range), the sampling path fully flushed, and readings stable.

2.2 Span Calibration

Span calibration adjusts the analyzer’s sensitivity near the full scale so that the measured value matches the standard gas concentration.

- Condition: Introduce certified calibration gas with a known concentration (e.g., 3 ppm CO₂).

- Requirement: Gas concentration must be accurate and stable, and match the value configured in the analyzer.

2.3 Calibration Protection Mechanism

To prevent operator errors from causing measurement drift:

- If the current reading deviates too far from the expected zero/span value, the analyzer will display a “Span Shift” or “Half Span Error” warning.

- In some firmware versions, a failed calibration triggers an automatic calibration lock, requiring reset/unlock before retrying.

3. Common Calibration Issues and Root Causes

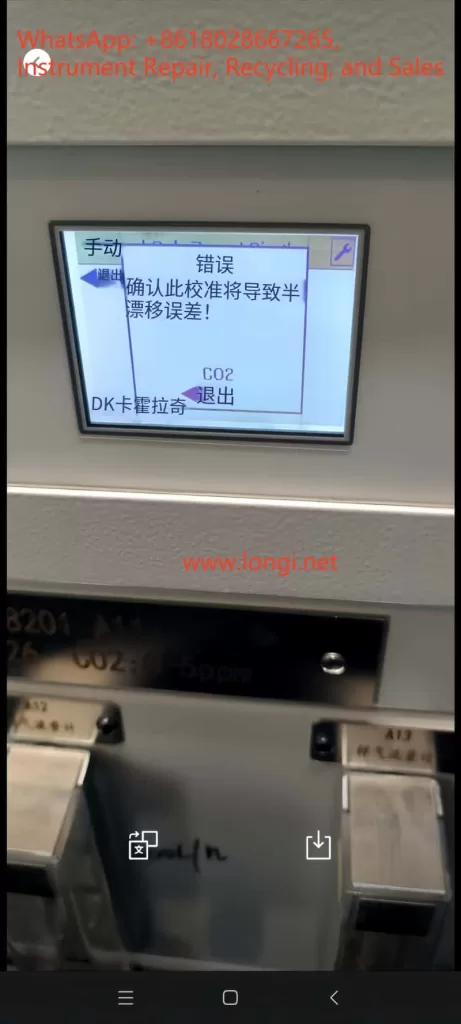

3.1 “Half Span Error” Warning

Causes:

- Incorrect calibration gas concentration (zero gas contains CO₂ or span gas concentration mismatch).

- Residual sample gas in the line or insufficient flushing time.

- Abnormal flow rate (too low/high or unstable).

- Analyzer not stabilized (insufficient warm-up or optical drift).

Recommendations:

- Verify calibration gas concentration and label match.

- Flush for ≥5–10 minutes before calibration.

- Adjust flow rate to recommended value (e.g., 60 L/h).

- Warm up for ≥30 minutes before calibration.

3.2 Zero Calibration Rejection

Causes:

- Current reading outside acceptable zero range (e.g., <0.1 ppm for a 0–5 ppm range).

- Calibration lock active after a failed attempt.

- Menu access restricted (requires service password).

Recommendations:

- Confirm zero gas purity (CO₂ < 0.1 ppm).

- Extend flushing until reading stabilizes.

- Check service menu for Calibration Reset option.

- If locked, perform unlock/reset before retrying.

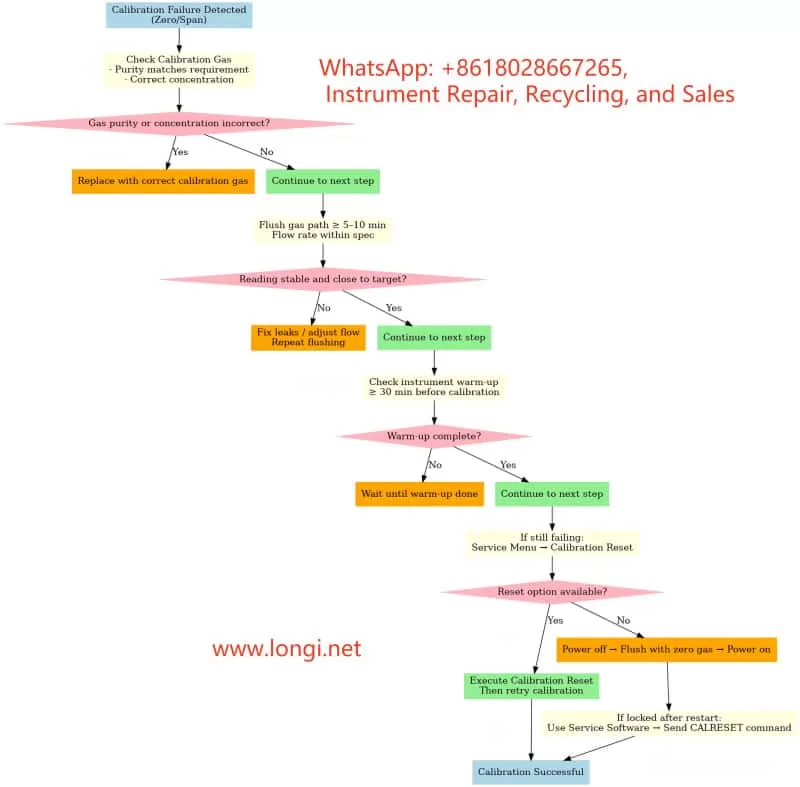

3.3 Lockout After One Failed Calibration

Causes:

- Firmware protection: Logs the failure and blocks further calibration until cleared.

- Data integrity protection: Prevents repeated incorrect calibrations from accumulating drift.

Unlock Methods:

- Menu Reset: Service → Calibration Reset.

- Power cycle + Zero gas flush.

- Factory Calibration Restore (use with caution – overwrites all current calibration data).

- Serial Command Unlock via ABB EL3020 Service Tool (

CALRESETcommand).

4. Field Troubleshooting and Operating Steps

4.1 Pre-Calibration Checklist

- Gas Verification

- Confirm gas label matches instrument settings.

- Use ≥99.999% high-purity nitrogen or equivalent zero gas.

- Flow and Gas Path

- Check flowmeter reading matches recommended spec.

- Inspect for leaks and verify valve positions.

- Warm-up and Stability

- Warm up for 30–60 minutes.

- Flush for 5–10 minutes after switching gases.

4.2 Calibration Execution

- Press the wrench icon on the right-hand side of the display to enter Maintenance Menu.

- Select Manual Calibration.

- Choose Zero Point or Span depending on the operation.

- Wait for the reading to stabilize before pressing OK.

- Verify reading changes after calibration completes.

4.3 After Calibration Failure

- Verify gas source → Flush → Retry.

- If still failing → Service Menu → Calibration Reset.

- If no reset option → Power cycle with zero gas flushing.

- If lock persists → Use service software via serial port to send

CALRESET.

5. Case Study: CO₂ Zero Point Calibration Failure

Scenario:

- Instrument: ABB EL3020 (0–5 ppm CO₂ range).

- Zero gas: 99.999% high-purity nitrogen.

- Flow rate: 60 L/h.

- Issue: Zero point calibration triggers “Half Span Error,” lockout after failure.

Investigation:

- Gas purity verified.

- Found flushing time was only 2 minutes – insufficient for stability.

- Extended flushing to 10 minutes → Reading dropped from 0.35 ppm to 0.05 ppm.

- Performed Calibration Reset → Zero point calibration succeeded.

Takeaway:

- Insufficient flushing time is a common cause.

- First step after failure: reset/unlock before retry.

6. Button & Icon Functions

- Left Icon (Envelope/File)

Data logging and viewing functions. Opens historical records and calibration logs. - Right Icon (Wrench)

Maintenance and calibration access: zero point, span calibration, gas path test, sensor status.

7. Preventive Maintenance Tips

- Regularly verify calibration gas purity to avoid contamination.

- Flush sampling lines thoroughly before calibration.

- Perform zero and span calibration according to manufacturer’s recommended cycle.

- Train operators to follow correct calibration procedures to minimize errors.

8. Conclusion

The ABB EL3020 (Uras26) offers stable, reliable high-precision gas analysis when paired with proper gas path management and calibration. Understanding the calibration principle, protection mechanism, and common failure modes enables operators to troubleshoot effectively and reduce downtime.

When calibration fails or lockout occurs, follow the outlined troubleshooting steps—starting from gas source and flow checks to warm-up, flushing, and finally reset/unlock procedures—to quickly restore normal operation.