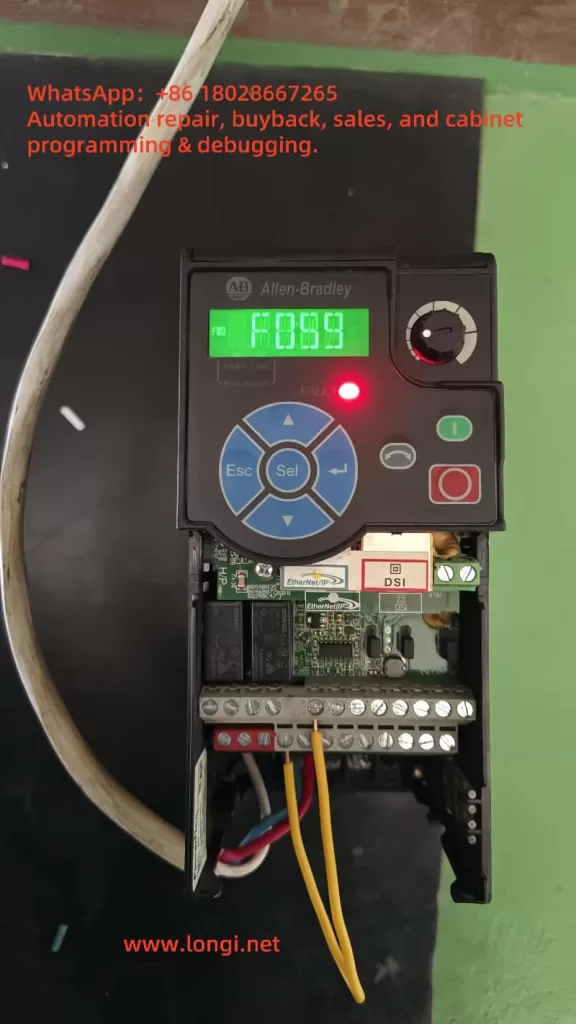

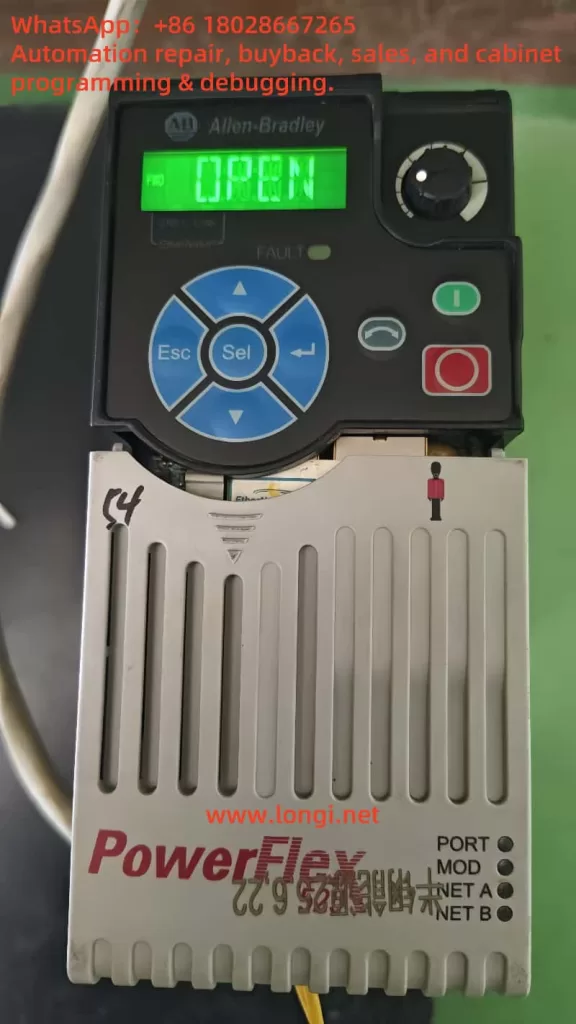

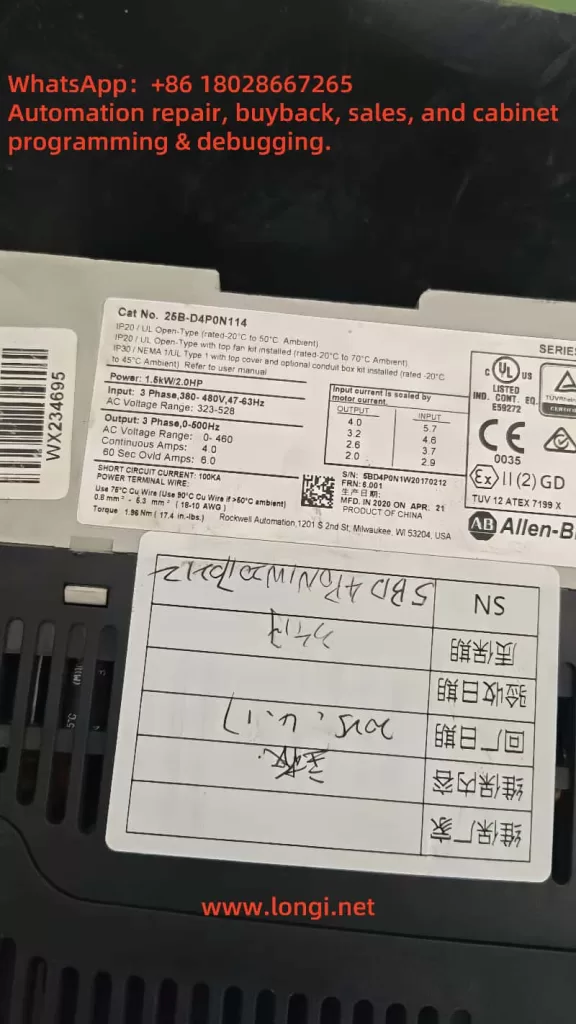

In modern industrial automation systems, variable frequency drives (VFDs) play a critical role. Allen-Bradley’s PowerFlex 525 series VFDs are widely used due to their high performance, strong communication capabilities, and flexible configuration, making them suitable for controlling fans, pumps, conveyors, and more. Despite its powerful features, the PowerFlex 525 often encounters error messages such as F059 or OPEN display, which can cause confusion during maintenance. This article provides a comprehensive analysis of the F059 fault and OPEN message, their causes, resolution methods, parameter configuration, and integration with EtherNet/IP systems. The goal is to help users quickly diagnose and recover system operation.

1. Meaning of Fault F059 and OPEN Display

F059 Fault Code Definition

F059 indicates “Safety Open.” This means the safety circuit is open. When the PowerFlex 525 detects that the safety input terminals (S1, S2) are not connected to the +24V terminal (S+), it interprets this as a safety circuit fault and triggers F059.

Meaning of OPEN Display

OPEN is a display message indicating the safety circuit is not closed. Unlike F059, it does not represent a fault but serves as a status alert, indicating the drive will not run until the circuit is restored.

Both signals stem from the same root cause: an open safety loop. However, F059 represents a fault, while OPEN is a passive status indication.

2. Common Causes and Diagnostics

1. Safety Circuit Not Jumped When Not in Use

If no external safety equipment (e.g., E-Stop or safety door) is used, S1 and S2 must be jumper-connected to S+ to simulate a closed loop. Without jumpers or if there is poor contact, F059 or OPEN will occur.

2. External Safety Devices Triggered or Disconnected

If a connected E-Stop or safety relay is open or faulty, it will open the safety circuit, leading to the error.

3. Improper Grounding or No Common Ground

The +24V safety circuit requires proper grounding. If the 24V power supply does not share a common ground with the drive, false F059 errors may occur.

4. Incorrect Control Parameter Configuration

Incorrect settings (e.g., T105 or T106) may prevent the drive from recovering from a safety status change.

3. Resolution and Jumper Wiring Methods

1. Jumper Method When Not Using Safety Input

If you are not using external safety devices, jumper S+ to both S1 and S2 as follows:

S+ ───┬──→ S1

└──→ S2

Use copper-core wire with secure tightening to avoid intermittent F059 faults.

2. Wiring Example With External Safety Devices

To use external safety devices (e.g., E-Stop button), insert the normally-closed contacts in series between S+ and S1/S2:

+24V (S+) ─────[E-Stop NC]───── S1

│

──────── S2

If the safety device opens, the drive will instantly shut off output for protection.

4. Key Parameter Configuration Guide

T105 – Safety Open Enable

- Location: Menu > Terminal Block > T105

- Default: 0 (safety enabled)

- Suggested: 1 (disable F059 fault)

When set to 1, an open safety circuit will only display “OPEN” and not trigger a fault.

T106 – SafetyFlt RstCfg

- Controls whether safety faults can be cleared via command

- Default: 0 (requires power cycle)

- Set to 1 to allow clearing via EtherNet/IP or panel

A541 / A542 – Auto Restart

These parameters allow the drive to auto-restart after a fault is cleared. Set a delay (e.g., 5 seconds) for unattended systems.

5. Clearing Faults via EtherNet/IP

When the drive is integrated with a PLC or HMI over EtherNet/IP, faults can be cleared remotely.

Steps:

- Ensure the safety circuit is re-closed (S1/S2 connected to S+)

- In the PLC, issue a “ClearFault” command or write Fault Object = 1

- The fault clears, and the drive returns to ready status

With T106 = 1 and auto-restart settings, the system can fully recover automatically.

6. Common Mistakes and Maintenance Advice

- Mistake 1: OPEN is still displayed even with T105 = 1 Solution: T105 only disables the F059 fault. OPEN will still show unless the safety circuit is closed or jumped.

- Mistake 2: Frequent F059 faults despite no hardware issues Solution: Check for loose terminals, aged wiring, and ensure 24V power supply shares a common ground with the drive.

- Tip: Periodically inspect terminal screws, wire integrity, and ensure reliable 0V grounding.

7. Summary and Application Scenarios

PowerFlex 525 has a well-designed safety management system offering both hardware jumpers and flexible software configuration. Combining jumper wiring, T105/T106 settings, and EtherNet/IP fault reset allows various use cases:

- Non-safety systems using jumper-only setup

- Systems using E-Stops and safety relays for machine protection

- Remote or automated systems with PLC-based safety recovery

These techniques improve system stability, reduce downtime, and balance both safety and operational efficiency.