1. Confirm Motor Model and Brake Parameters

- Model: MSK071E-0303-FN-M1-UG2-NNNN

- Nameplate Parameters: Brake 30Ω, DC 24V ±10%, 0.94A

👉 Indicates that this motor is equipped with a DC brake, rated for a working voltage of 24VDC, which releases the brake when powered and locks it when de-energized.

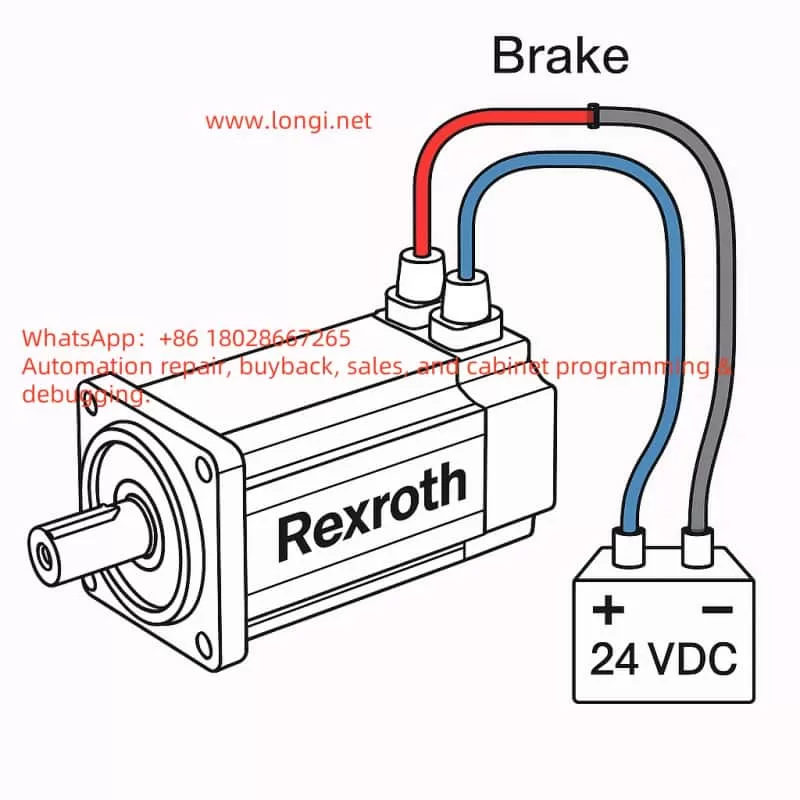

2. Wiring Identification

- Red Wire → +24VDC

- Blue Wire → 0V (Negative)

- (Gray Wire Pair) = Temperature Sensor, not involved in brake testing.

3. Power Supply Preparation

- Use a regulated 24VDC power supply with a rated current of ≥2A (reserve a margin, although normal operation requires approximately 1A).

- The power supply should have overcurrent protection to prevent damage from short circuits.

- If possible, it is best to use a power supply with soft start or current limiting functions.

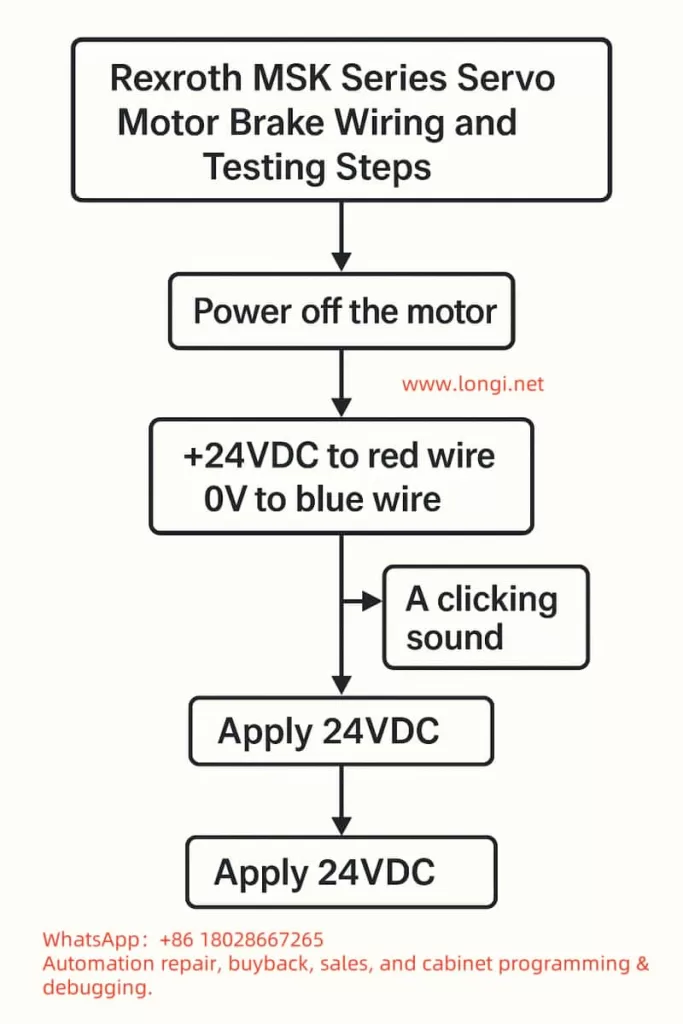

4. Testing Steps

- Disconnect the motor and confirm that the motor’s main power supply is not connected.

- Connect the positive terminal of the power supply to the red wire and the negative terminal to the blue wire.

- Apply 24VDC power:

- You should hear a “click” sound, indicating that the brake has been released.

- Gently rotate the motor shaft by hand; it should rotate freely.

- Disconnect the 24VDC power supply:

- Attempt to rotate the motor shaft again; it should be locked by the mechanical brake.

5. Precautions

- Never operate the motor shaft for extended periods with the brake continuously powered without control from a motor driver, as excessive inertia from shaft rotation may damage the brake pads.

- In practical applications with a driver, the brake signal is usually controlled by the driver’s Brake Output; do not continuously apply direct power.

- If the brake fails to release, check the following:

- Whether the power supply voltage is within 24V ±10%.

- Whether the power supply current is sufficient.

- Whether the red/blue wires are reversed (reversing them will prevent release).

✅ Summary:

- Red → +24VDC, Blue → 0V

- Power on to release, power off to lock.

- Testing method: Listen for sound, rotate shaft.