1. Fault Definition and Background

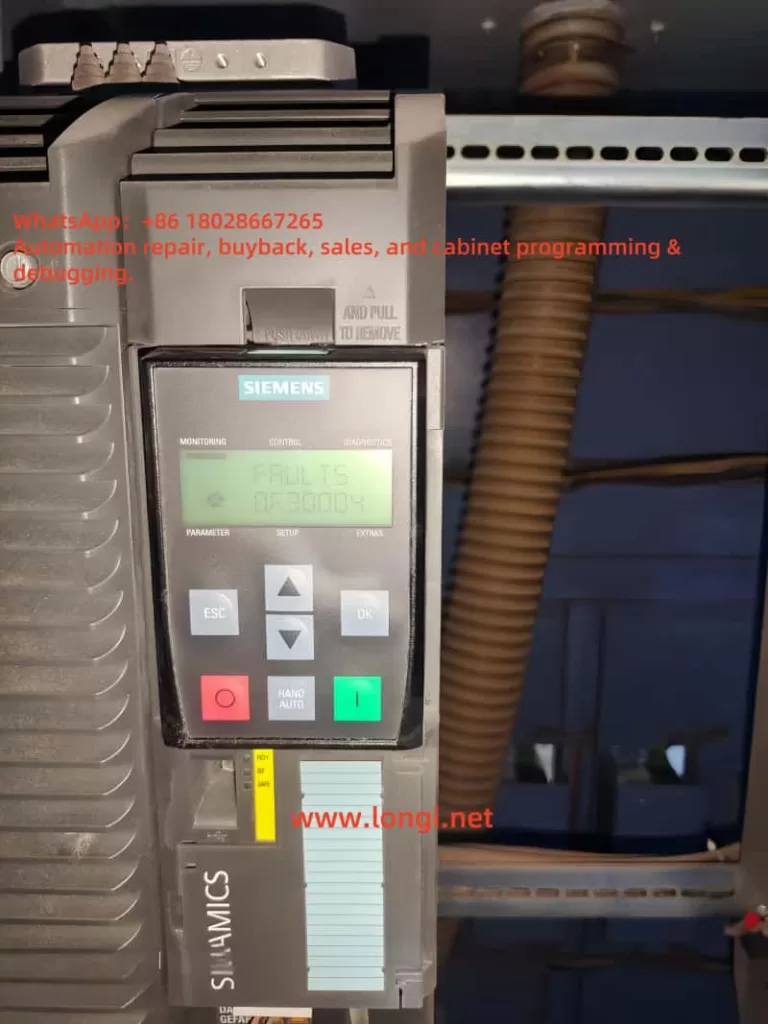

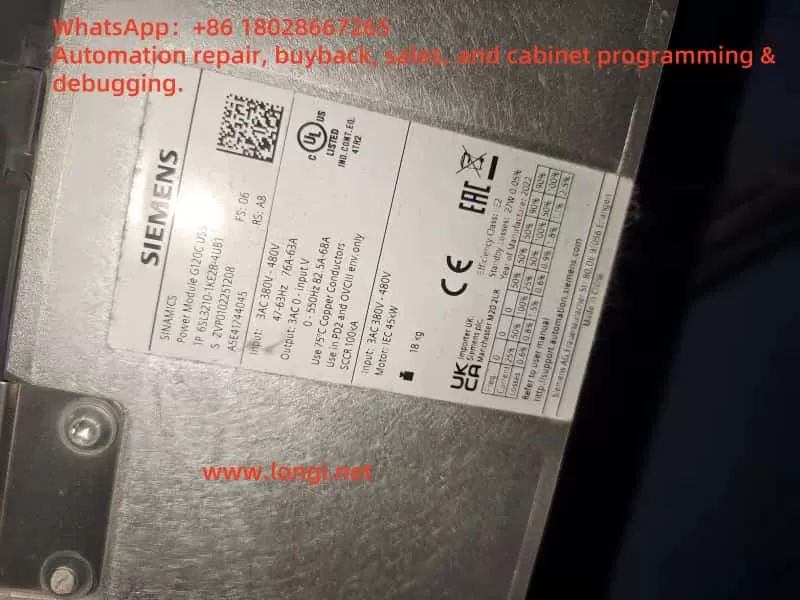

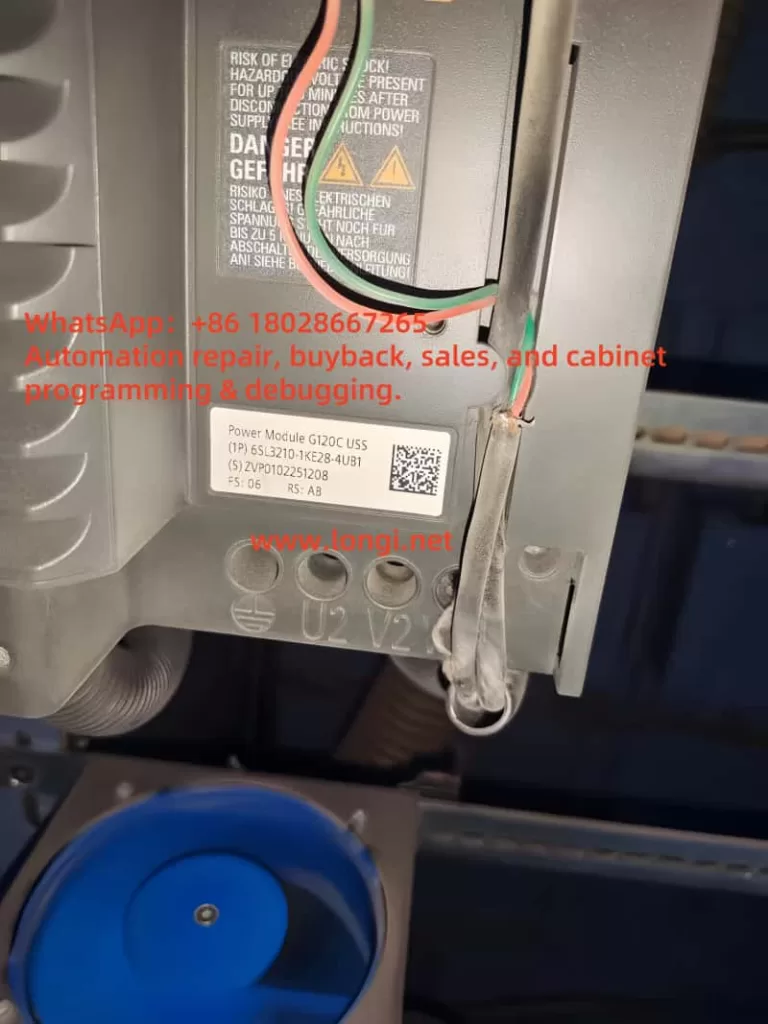

The “F30004” fault is a common error code in the SINAMICS G120C series of Siemens inverters. It indicates:

- Power unit: Overtemperature heatsink AC inverter

In other words, the temperature of the power module’s heatsink has exceeded the permissible threshold. When the heatsink temperature reaches a warning level (typically around 5°C below the fault threshold), the inverter will raise an alarm (A05000). If the temperature continues to rise, it will escalate into fault F30004, leading to an immediate shutdown.

2. Possible Causes of F30004

Based on official documentation and field experience, the core causes of F30004 can be categorized as:

- Cooling Fan Failure

- Internal fans may become jammed, damaged, or run at reduced speed, preventing effective heat dissipation.

- Blocked or Poor Heatsink Ventilation

- Dust accumulation or airflow obstruction can significantly reduce the cooling capacity of the heatsink.

- High Ambient Temperature

- According to the manual, the intake air temperature for air-cooled drives should not exceed 42°C. Exceeding this temperature will increase thermal stress.

- Overload or High System Load

- The drive may be continuously running at high torque or with excessive mechanical load, leading to heat buildup in the power module.

- Excessively High Pulse Frequency (Switching Frequency)

- While high switching frequency improves output wave quality, it also increases internal power loss and heating.

- Sensor or Parameter Issues

- Although rare, a malfunctioning temperature sensor or incorrect settings may lead to false overheating detection.

3. Diagnostic Steps for F30004

Upon encountering an F30004 fault, follow this step-by-step diagnostic procedure:

1. Check for Preceding Warnings

Use the BOP/IOP panel or engineering software to check if warning A05000 appeared before the F30004 fault. This can confirm if the fault was due to gradual overheating rather than an instant anomaly.

2. Inspect the Cooling Fan

- Listen for fan noise or visually inspect fan rotation.

- Remove the fan to check for blockages or dust.

- Replace the fan module if it shows signs of failure or aging.

3. Evaluate Ambient and Ventilation Conditions

- Measure the internal cabinet or intake air temperature.

- Clean all dust and obstruction near the heatsink or vent path.

- Improve ventilation or consider adding a cabinet cooling fan or air conditioning unit if needed.

4. Check Load Conditions

- Verify whether the motor is running with excessive load or mechanical resistance.

- Inspect parameter settings such as p0640 or p1341 (current limits).

- If operating near thermal limits for extended periods, reduce load or increase cooldown intervals.

5. Reduce Pulse Frequency

- Use parameter p1800 to lower the switching frequency.

- Avoid unnecessarily high values that can accelerate heat generation.

6. Validate Temperature Sensor

- Read diagnostic values such as r2124 and r0037.

- Replace the sensor or disable overheating fault response if the sensor is faulty.

4. Solutions and Preventive Measures

4.1 Immediate Fixes

- Let the inverter cool down before clearing the fault.

- Verify all hardware and environmental factors before restarting.

- Reset the fault using the control panel or via software tools.

4.2 Long-Term Prevention

- Routine Maintenance

- Clean the inverter regularly, especially the heatsink, fan blades, and air filters.

- Temperature Monitoring and Thermal Management

- Install a cabinet temperature sensor and configure automatic cooling triggers.

- Fan Replacement Strategy

- Implement predictive maintenance based on fan usage hours or set a replacement schedule.

- Optimize Load and Parameters

- Avoid long-term high torque operations.

- Set appropriate acceleration/deceleration times.

- Adjust Switching Frequency Wisely

- Do not set p1800 too high unless required by motor or application.

- Configure Redundant Monitoring (if applicable)

- Some models support backup temperature detection or allow disabling fault response under certain safety-controlled conditions.

5. Conclusion and Insights

The F30004 fault in SINAMICS G120C is essentially a protective shutdown triggered by thermal overload. It’s often the result of long-term thermal stress rather than sudden failure. The key principles in addressing it are:

- Diagnose Systematically: Start from fan, environment, load, parameters, and sensors.

- Recover Cautiously: Clear the fault only after ensuring proper cooling and safe conditions.

- Prevent Proactively: Use regular maintenance, parameter tuning, and environmental control.

Unlike faults caused by short circuits or ground failures, thermal faults may seem benign at first, but repeated F30004 events can severely degrade inverter life or lead to power module damage. Preventive measures and automated monitoring are essential to ensure long-term reliable operation.

6. Additional Recommendations

- Install a temperature probe in the cabinet to monitor in real-time;

- Activate pre-warning thresholds to raise an alarm before reaching F30004;

- Monitor for F30035 (intake overtemperature) as it often occurs alongside F30004;

- Entrust trained professionals to replace internal fans or disassemble power modules.

This in-depth analysis of fault code F30004 aims to help users not only resolve current errors but also establish best practices in long-term inverter maintenance. For advanced technical assistance, consult Siemens’ certified support service.