Introduction

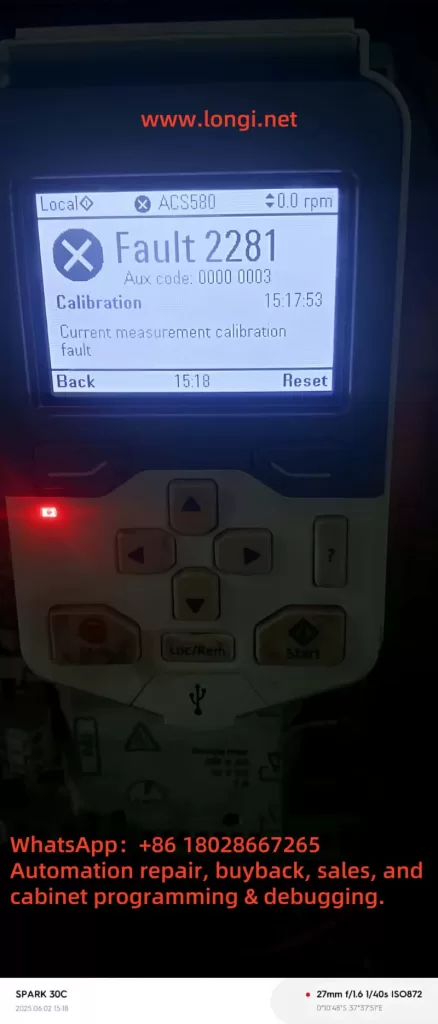

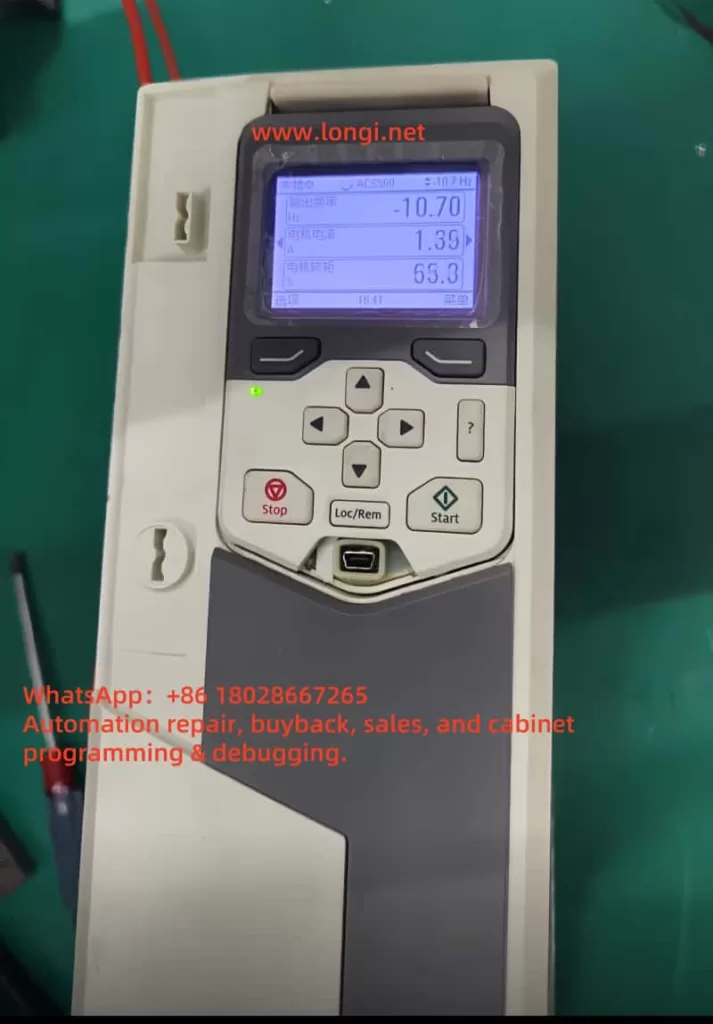

The ABB ACS580 is a robust and reliable Variable Frequency Drive (VFD) widely used in industrial applications for precise control of AC motors. However, like any complex electronic device, the ACS580 may encounter faults that require troubleshooting and maintenance. One common issue is “Fault 2281,” which is related to current measurement calibration. This document provides a detailed explanation of the causes of Fault 2281, the roles of parameters 99.13 and 99.14, and a step-by-step guide to resolving this fault, ensuring the drive returns to normal operation. This guide is designed to offer clear and practical solutions for technicians and engineers while ensuring operational safety and equipment efficiency.

What is Fault 2281?

Fault 2281 indicates an issue with the current measurement calibration of the ACS580 drive. This fault is typically triggered by the following reasons:

- Excessive Measurement Offset: The measurement offset of the output phase currents exceeds the allowable range.

- Interphase Discrepancy: The current measurement difference between output phases U2 and W2 is too large.

- Incorrect Calibration Completion: The initial setup or previous calibration process may not have been executed correctly.

- Hardware Issues: There may be faults in the current sensors, connecting cables, or the drive’s internal circuitry.

- Environmental Interference: External factors such as temperature and electromagnetic interference may affect calibration stability.

- Firmware Issues: The drive’s firmware version may be incompatible with the calibration requirements.

Fault 2281 is usually displayed on the drive’s display as “Fault 2281” with an auxiliary code (e.g., “0000 0003”), indicating the specific problem. Failing to resolve this fault may lead to inaccurate motor control, overheating, or equipment damage, making timely resolution crucial.

Why is Current Measurement Calibration Important?

Current measurement is one of the core functions of a VFD, directly affecting the drive’s performance and safety. Accurate current measurement serves the following purposes:

- Device Protection: By monitoring the current, the drive can detect overloads, short circuits, or other anomalies and take protective measures (such as tripping or decelerating).

- Performance Optimization: Precise current control ensures accurate motor torque regulation, suitable for applications requiring smooth operation.

- Energy Efficiency: Reduces energy waste by adjusting motor speed according to load demands.

- Diagnostic Support: Provides reliable current data for fault diagnosis and predictive maintenance.

If current measurement is not correctly calibrated, it may result in:

- Torque control errors affecting motor performance.

- Incorrect tripping or failure to trip, increasing the risk of equipment damage.

- Inefficient operation, wasting energy.

- Unreliable diagnostic data, complicating fault troubleshooting.

Therefore, regular calibration of the current measurement system is key to ensuring the efficient and reliable operation of the ACS580 drive.

Roles of Parameters 99.13 and 99.14

In the ACS580 drive, parameters 99.13 and 99.14 belong to the “Motor Parameters” group (Group 99) and are used to configure and execute Identification Run (ID Run), including current measurement calibration.

Parameter 99.14: Identification Run Condition

Parameter 99.14 is used to select the type of identification run. According to the provided documentation, the possible values for parameter 99.14 include:

| Value | Description | English Translation |

|---|---|---|

| 0 | No identification operation | No identification operation |

| 1 | Standard identification operation | Standard identification operation |

| 2 | Simplified identification operation | Simplified identification operation |

| 3 | Static identification operation | Static identification operation |

| 4 | Reserved | Reserved |

| 5 | Current measurement calibration | Current measurement calibration |

| 6 | Advanced identification operation | Advanced identification operation |

Setting parameter 99.14 to 5 indicates that the drive will perform current measurement calibration to adjust the internal current measurement system for accuracy.

Parameter 99.13: Identification Run Request

Parameter 99.13 is used to initiate the identification run. According to the ABB ACS580 firmware manual, this parameter allows the user to request the drive to execute an identification run, the specific type of which is defined by parameter 99.14. After setting parameter 99.13, the drive will perform the corresponding operation based on the setting in 99.14, such as current measurement calibration.

Synergy Between the Two Parameters

- 99.14 specifies the operation type (e.g., a value of 5 indicates current measurement calibration).

- 99.13 triggers the identification run, initiating the calibration process.

By correctly setting these two parameters, users can recalibrate the current measurement system to resolve Fault 2281.

Steps to Execute Current Measurement Calibration

Below are the detailed steps to resolve Fault 2281 by setting parameters 99.13 and 99.14 to execute current measurement calibration:

- Ensure Safety

- Power Off: Disconnect the drive from the power source to ensure complete de-energization and avoid electrical hazards.

- Isolate the Motor: Ensure the motor has stopped and is disconnected from the load to prevent accidental startup.

- Check the Environment: Ensure the working environment is free from electromagnetic interference or extreme temperatures that could affect the calibration.

- Access the Parameter Menu

- Control Panel: On the ACS580 drive’s control panel, press the “Menu” or “Parameters” button to enter the parameter setup mode.

- PC Tool: Use the ABB Drive Composer software to connect to the drive via the appropriate communication port and open the parameter setup interface.

- Navigate to the Motor Parameters Group

- On the control panel, use the navigation buttons to scroll to “Motor Parameters” or Group 99.

- In Drive Composer, browse the parameter list to find Group 99 (Motor Data).

- Set Parameter 99.14

- Locate parameter 99.14 (Identification Run Condition).

- Set its value to 5 (Current Measurement Calibration). Depending on the interface, this may involve selecting from a dropdown list or manually entering “5”.

- Initiate the Identification Run

- Locate parameter 99.13 (Identification Run Request).

- Set this parameter to initiate the identification run. Typically, this involves selecting “Start ID Run” or entering a specific value (refer to the manual for specific operations).

- Monitor the Calibration Process

- The drive will perform current measurement calibration, which may last from a few seconds to a minute, depending on the drive and motor configuration.

- Observe the control panel display for progress information or error messages.

- Verify the Calibration Results

- After calibration is complete, check the drive’s display to confirm whether Fault 2281 has been cleared.

- Use an external current measurement device (such as a current clamp) to verify that the current values displayed by the drive match the actual values.

- Save the Parameters

- Save the changed parameter settings to ensure they are retained after a power outage.

- On the control panel, this is usually done by selecting “Save” or “Confirm”; in Drive Composer, choose “Save Parameters”.

Troubleshooting Tips

If Fault 2281 persists after calibration, try the following methods:

- Check Hardware Connections: Ensure the current sensors, motor cables, and terminal blocks are secure and free from loose connections or damage.

- Check Hardware Integrity: Inspect the drive’s interior for physical damage or current sensor failures.

- Verify Firmware Version: Ensure the drive’s firmware is up to date. The document mentions that versions below 99.7.3 may require calibration support from ABB Drives.

- Refer to the Manual: Consult the ACS580 user manual’s troubleshooting section for specific meanings of auxiliary codes (such as 0000 0003).

- Contact Technical Support: If the issue persists, contact technical support, providing the fault code, auxiliary code, and steps already attempted.

Common Errors and How to Avoid Them

When performing calibration, avoid the following common errors:

- Not Powering Off: Ensure the drive is powered off before adjusting parameters to prevent unexpected behavior or safety risks.

- Incorrect Parameter Settings: Confirm that you are adjusting parameters 99.13 and 99.14 and that their values are correct (99.14 set to 5).

- Skipping Verification: After calibration, check if the fault has been cleared and verify the accuracy of the current measurement.

- Ignoring Hardware Issues: If calibration is ineffective, check for hardware issues such as loose connections or damaged sensors.

Conclusion

Current measurement calibration is a critical step in ensuring the efficient and reliable operation of the ABB ACS580 drive. Fault 2281 indicates that the current measurement system needs recalibration. By correctly using parameters 99.13 and 99.14 and following the steps provided in this document, you can effectively resolve this fault and restore the drive to normal operation. Regular maintenance and calibration checks help prevent similar issues, extend equipment life, and maintain production efficiency. For further assistance, refer to the official documentation or contact ABB technical support.

Appendix: Parameter 99.14 Value Table

| Value | Description | English Translation |

|---|---|---|

| 0 | No identification operation | No identification operation |

| 1 | Standard identification operation | Standard identification operation |

| 2 | Simplified identification operation | Simplified identification operation |

| 3 | Static identification operation | Static identification operation |

| 4 | Reserved | Reserved |

| 5 | Current measurement calibration | Current measurement calibration |

| 6 | Advanced identification operation | Advanced identification operation |