Introduction

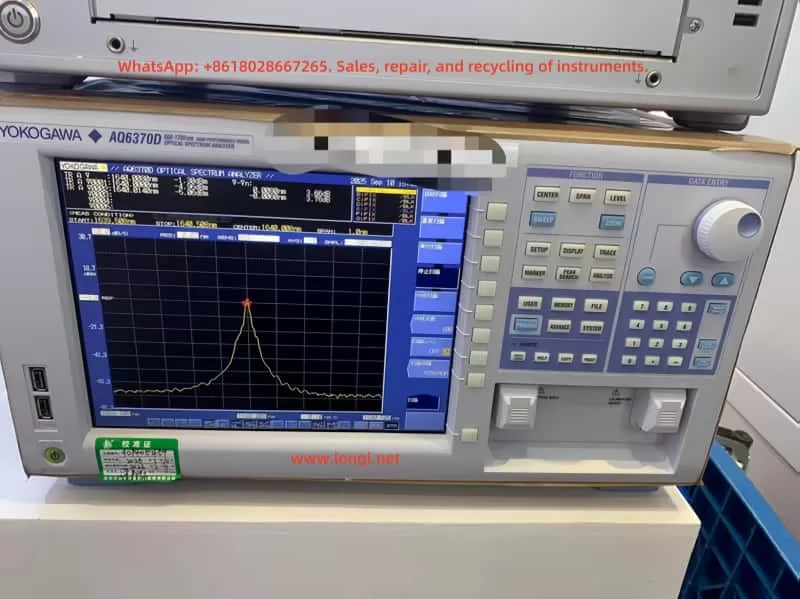

The Yokogawa AQ6370D series optical spectrum analyzer is a high-performance and multifunctional testing instrument widely used in various fields such as optical communication, laser characteristic analysis, fiber amplifier testing, and WDM system analysis. With its high wavelength accuracy, wide dynamic range, and rich analysis functions, it has become an indispensable tool in research and development as well as production environments.

This article, closely based on the content of the AQ6370D Optical Spectrum Analyzer User’s Manual, systematically introduces the device’s operating procedures, functional modules, usage tips, and precautions. It aims to help users quickly master the device’s usage methods and improve testing efficiency and data reliability.

I. Device Overview and Initial Setup

1.1 Device Structure and Interfaces

The front panel of the AQ6370D is richly laid out, including an LCD display, soft key area, function key area, data input area, optical input interface, and calibration output interface. The rear panel provides various interfaces such as GP-IB, TRIGGER IN/OUT, ANALOG OUT, ETHERNET, and USB, facilitating remote control and external triggering.

Key Interface Descriptions:

- OPTICAL INPUT: This is the optical signal input interface that supports common fiber connectors such as FC/SC.

- CALIBRATION OUTPUT: Only the -L1 model has this built-in reference light source output interface for wavelength calibration.

- USB Interface: Supports external devices such as mice, keyboards, and USB drives for easy operation and data export.

1.2 Installation and Environmental Requirements

To ensure normal operation of the device, the installation environment should meet the following conditions:

- Temperature: Maintain between 5°C and 35°C.

- Humidity: Not exceed 80% RH, and no condensation should occur.

- Environment: Avoid environments with vibrations, direct sunlight, excessive dust, or corrosive gases.

- Space: Provide at least 20 cm of ventilation space around the device.

Note: The device weighs approximately 19 kg. When moving it, ensure two people operate it together and that the power is turned off.

II. Power-On and Initial Calibration

2.1 Power-On Procedure

- Connect the power cord to the rear panel and plug it into a properly grounded three-prong socket.

- Turn on the MAIN POWER switch on the rear panel. The POWER indicator on the front panel will turn orange.

- Press the POWER key to start the device, which will enter the system initialization interface.

- After initialization, if it is the first use or the device has been subjected to vibrations, the system will prompt for alignment adjustment and wavelength calibration.

2.2 Alignment Adjustment

Alignment adjustment aims to calibrate the optical axis of the built-in monochromator to ensure optimal optical performance.

Using Built-in Light Source (-L1 Model):

- Connect the CAL OUTPUT and OPTICAL INPUT using a 9.5/125 μm single-mode fiber.

- Press SYSTEM → OPTICAL ALIGNMENT → EXECUTE.

- Wait approximately 2 minutes, and the device will automatically complete alignment and wavelength calibration.

Using External Light Source (-L0 Model):

- Connect an external laser source (1520–1560 nm, ≥-20 dBm) to the optical input port.

- Enter SYSTEM → OPTICAL ALIGNMENT → EXTERNAL LASER → EXECUTE.

2.3 Wavelength Calibration

Wavelength calibration ensures the accuracy of measurement results.

Using Built-in Light Source:

Enter SYSTEM → WL CALIBRATION → BUILT-IN SOURCE → EXECUTE.

Using External Light Source:

Choose EXECUTE LASER (laser type) or EXECUTE GAS CELL (gas absorption line type) and input the known wavelength value.

Note: The device should be preheated for at least 1 hour before calibration, and the wavelength error should not exceed ±5 nm (built-in) or ±0.5 nm (external).

III. Basic Measurement Operations

3.1 Auto Measurement

Suitable for quick measurements of unknown light sources:

- Press SWEEP → AUTO, and the device will automatically set the center wavelength, scan width, reference level, and resolution.

- The measurement range is from 840 nm to 1670 nm.

3.2 Manual Setting of Measurement Conditions

- Center Wavelength/Frequency: Press the CENTER key to directly input a value or use PEAK→CENTER to set the peak as the center.

- Scan Width: Press the SPAN key to set the wavelength range or use Δλ→SPAN for automatic setting.

- Reference Level: Press the LEVEL key to set the vertical axis reference level, supporting PEAK→REF LEVEL for automatic setting.

- Resolution: Press SETUP → RESOLUTION to choose from various resolutions ranging from 0.02 nm to 2 nm.

3.3 Trigger and Sampling Settings

- Sampling Points: The range is from 101 to 50,001 points, settable via SAMPLING POINT.

- Sensitivity: Supports multiple modes such as NORM/HOLD, NORM/AUTO, MID, HIGH1~3 to adapt to different power ranges.

- Average Times: Can be set from 1 to 999 times to improve the signal-to-noise ratio.

IV. Waveform Display and Analysis Functions

4.1 Trace Management

The device supports 7 independent traces (A~G), each of which can be set to the following modes:

- WRITE: Real-time waveform update.

- FIX: Fix the current waveform.

- MAX/MIN HOLD: Record the maximum/minimum values.

- ROLL AVG: Perform rolling averaging.

- CALCULATE: Implement mathematical operations between traces.

4.2 Zoom and Overview

The ZOOM function allows local magnification of the waveform, supporting mouse-drag selection of the area. The OVERVIEW window displays the global waveform and the current zoomed area for easy positioning.

4.3 Marker Function

- Moving Marker: Displays the current wavelength and level values.

- Fixed Marker: Up to 1024 can be set to display the difference from the moving marker.

- Line Marker: L1/L2 are wavelength lines, and L3/L4 are level lines, used to set scan or analysis ranges.

- Advanced Marker: Includes power spectral density markers, integrated power markers, etc., supporting automatic search for peaks/valleys.

4.4 Trace Math

Supports operations such as addition, subtraction, normalization, and curve fitting between traces, suitable for differential measurements, filter characteristic analysis, etc.

Common Calculation Modes:

- C = A – B: Used for differential analysis.

- G = NORM A: Normalize the display.

- G = CRV FIT A: Perform Gaussian/Lorentzian curve fitting.

V. Advanced Measurement Functions

5.1 Pulsed Light Measurement

Supports three modes:

- Peak Hold: Suitable for repetitive pulsed measurements.

- Gate Sampling: Synchronized sampling with an external gate signal.

- External Trigger: Suitable for non-periodic pulsed measurements.

5.2 External Trigger and Synchronization

- SMPL TRIG: Wait for an external trigger for each sampling point.

- SWEEP TRIG: Wait for an external trigger for each scan.

- SMPL ENABLE: Perform scanning when the external signal is low.

5.3 Power Spectral Density Display

Switch to dBm/nm or mW/nm via LEVEL UNIT, suitable for normalized power display of broadband light sources (such as LEDs, ASE).

VI. Data Analysis and Template Judgement

6.1 Spectral Width Analysis

Supports four algorithms:

- THRESH: Threshold method.

- ENVELOPE: Envelope method.

- RMS: Root mean square method.

- PEAK RMS: Peak root mean square method.

6.2 Device Analysis Functions

- DFB-LD SMSR: Measure the side-mode suppression ratio.

- FP-LD/LED Total Power: Calculate the total optical power through integration.

- WDM Analysis: Simultaneously analyze multiple channel wavelengths, levels, and OSNR.

- EDFA Gain and Noise Figure: Calculate based on input/output spectra.

6.3 Template Judgement (Go/No-Go)

Upper and lower limit templates can be set for quick judgement in production lines:

- Upper limit line, lower limit line, target line.

- Supports automatic judgement and output of results.

VII. Data Storage and Export

7.1 Storage Media

Supports USB storage devices for saving waveform data, setting files, screen images, analysis results, etc.

7.2 Data Formats

- CSV: Used to store analysis result tables.

- BMP/PNG: Used to save screen images.

- Internal Format: Supports subsequent import and re-analysis.

7.3 Logging Function (Data Logging)

Can periodically record WDM analysis, peak data, etc., suitable for long-term monitoring and statistical analysis.

VIII. Maintenance and Troubleshooting

8.1 Routine Maintenance

- Regularly clean the fiber end faces and connectors.

- Avoid direct strong light input to prevent damage to optical components.

- Use the original packaging for transportation to avoid vibrations.

8.2 Common Problems and Solutions

| Problem Phenomenon | Possible Causes | Solutions |

|---|---|---|

| Large wavelength error | Not calibrated or temperature not stable | Perform wavelength calibration and preheat for 1 hour |

| Inaccurate level | Fiber type mismatch | Use 9.5/125 μm SM fiber |

| Scan interruption | Excessive sampling points or high resolution | Adjust sampling points or resolution |

| USB drive not recognized | Incompatible format | Format as FAT32 and avoid partitioning |

IX. Conclusion

The Yokogawa AQ6370D series optical spectrum analyzer is a comprehensive and flexible high-precision testing device. By mastering its basic operations and advanced functions, users can efficiently complete various tasks ranging from simple spectral measurements to complex system analyses. This article, based on the official user manual, systematically organizes the device’s usage procedures and key technical points, hoping to provide practical references for users and further improve testing efficiency and data reliability.