— Practical Insights into D108, AFE2, and A7C1 Alarms

Introduction

The ABB ACS880 drive series, as a new-generation industrial variable frequency drive, is widely applied in cranes, hoists, metallurgy, mining, petrochemical, and other heavy-duty fields. Built on Direct Torque Control (DTC) technology, the ACS880 supports multiple control modes (speed, torque, frequency, process PID) and provides extensive I/O interfaces and fieldbus modules for flexible configuration.

In demanding operating environments, the ACS880 inevitably encounters alarms and faults. Common issues include “End limits I/O error (D108),” “Emergency stop (AFE2),” and “Fieldbus adapter communication warning (A7C1).” This article explores these cases by combining insights from the ACS880 firmware manual and real-world troubleshooting, covering fault mechanisms, root causes, diagnostic procedures, and corrective measures.

I. Overview of ACS880 Control System

1.1 Control Panel and Local/Remote Modes

The ACS880 uses the ACS-AP-x control panel as the human-machine interface. Control can be set to:

- Local control (LOC): Commands originate from the keypad or DriveComposer PC tool.

- Remote control (REM/EXT1/EXT2): Commands are provided via I/O, fieldbus, or external controllers.

1.2 I/O Architecture and Signal Flow

- DI/DO: For limit switches, emergency stops, start/stop logic.

- AI/AO: For speed, current, or process feedback signals.

- RO: Relay outputs for run/fault status.

- Fieldbus interface: Supports PROFIBUS, PROFINET, EtherNet/IP, etc.

1.3 Protection and Fault Logic

The ACS880 provides a wide range of protection functions:

- Motor thermal protection, overcurrent, overvoltage, undervoltage.

- I/O loop monitoring (limit switches/emergency stops).

- Communication timeout protection.

Faults are indicated via Fault codes and warnings via Warning codes.

II. Analysis of Typical Fault Cases

2.1 D108 – End Limits I/O Error

(1) Definition

Indicates an abnormal input from end limit switches, often in crane or hoist applications.

(2) Possible Causes

- Damaged or stuck limit switch.

- Loose or broken DI wiring.

- Incorrect I/O parameter mapping.

- Logic mismatch (NC contact configured as NO).

(3) Diagnostic Steps

- Test switch continuity with a multimeter.

- Inspect wiring and grounding at terminals.

- Verify parameters 10.01–10.10 (DI configuration).

- Check parameter group 04 (Warnings and Faults) for I/O status.

(4) Solutions

- Repair or replace faulty switches.

- Re-tighten wiring connections.

- Correct I/O parameter mapping.

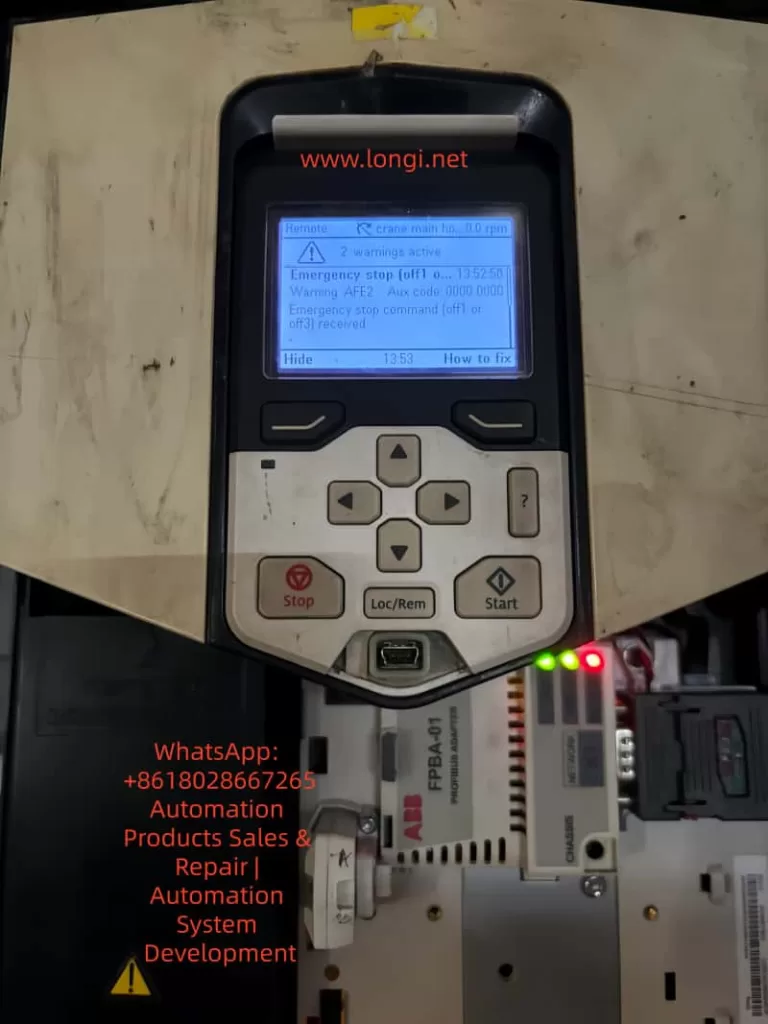

2.2 AFE2 – Emergency Stop (OFF1/OFF3)

(1) Definition

Triggered when the emergency stop circuit is activated, via OFF1/ OFF3 inputs.

(2) Possible Causes

- Emergency stop button pressed.

- Relay or contactor in the safety loop has opened.

- Loose wiring or oxidized contacts.

(3) Diagnostic Steps

- Verify emergency stop button reset status.

- Measure OFF1/ OFF3 input voltage.

- Check parameters 20.01–20.10 (Start/Stop configuration).

(4) Solutions

- Reset E-stop button.

- Replace defective relays or contactors.

- Correct safety loop parameter mapping.

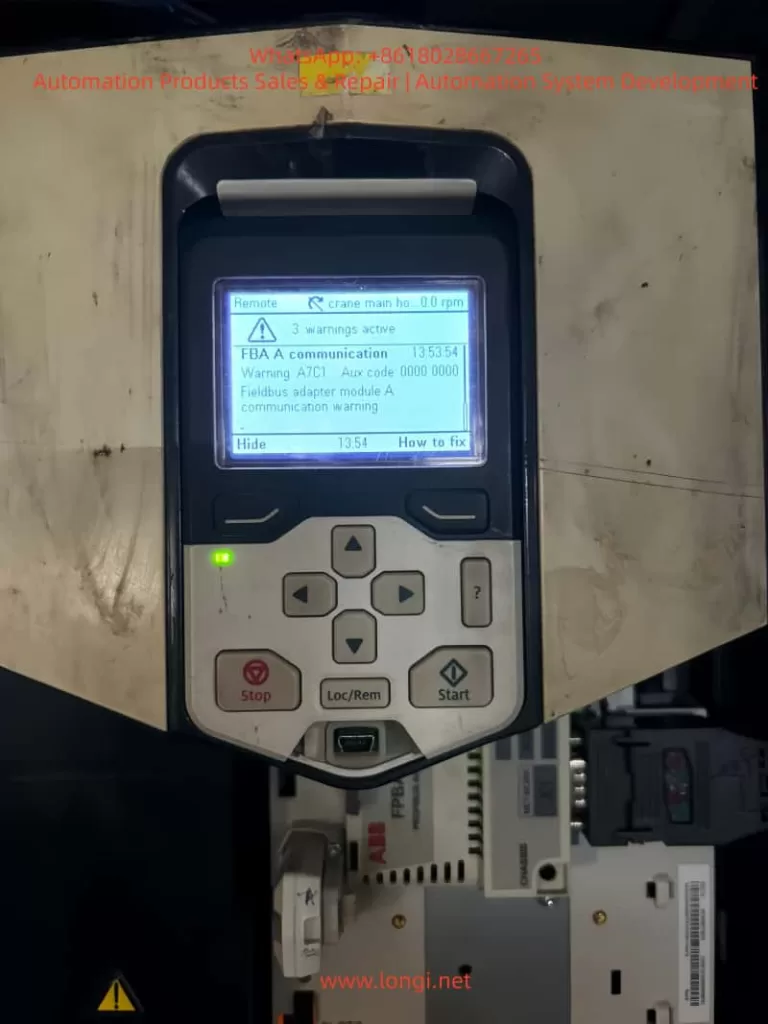

2.3 A7C1 – Fieldbus Adapter Communication Warning

(1) Definition

Indicates communication issues with fieldbus adapter modules such as PROFIBUS/PROFINET FPBA-01.

(2) Possible Causes

- Loose or damaged communication cable.

- Mismatched station number/baud rate between PLC and drive.

- Defective fieldbus module.

(3) Diagnostic Steps

- Check cable connections and shielding.

- Compare station number, baud rate, protocol in PLC and drive.

- Review parameters in group 50/51 (FBA settings).

- Replace FBA module if required.

(4) Solutions

- Reconnect or replace cables.

- Align PLC and drive communication settings.

- Replace or upgrade the module.

III. Systematic Fault Handling in ACS880

3.1 Fault Reset and History Review

- Use the panel “Reset” button or DI input reset.

- Review fault history in group 04 (Warnings/Faults) and group 08 (Fault tracing).

3.2 Signal Monitoring and Diagnostics

- Monitor I/O status in group 05 (Diagnostics).

- Use DriveComposer to trace communication, I/O, and motor signals in real time.

3.3 Maintenance and Prevention

- Regularly inspect limit switches and emergency stop devices.

- Test communication cables periodically.

- Enable automatic fault reset (parameter 31.07) to avoid shutdowns from transient errors.

IV. Application Scenarios and Best Practices

4.1 Crane Systems

- D108 faults often arise from unstable up/down limit switch signals.

- Best practice: dual redundant limit switches plus PLC software limits.

4.2 Metallurgy Hoists

- AFE2 alarms frequently result from worn safety contactors.

- Recommendation: replace relays periodically and enable mechanical brake control (group 44).

4.3 Automated Production Lines

- A7C1 warnings usually caused by configuration mismatches.

- Best practice: export/import FBA configuration files for multiple drives to ensure uniformity.

V. Conclusion

The ABB ACS880 faults D108, AFE2, and A7C1 essentially correspond to I/O errors, emergency stop activation, and communication failures. A structured troubleshooting approach—hardware check → parameter verification → history analysis → module replacement—enables fast problem resolution.

Leveraging the ACS880 firmware manual’s detailed guidance on I/O parameters, fieldbus setup, and fault tracing functions, maintenance teams can not only solve existing issues but also implement preventive measures, reducing downtime and improving system reliability.