The YT-3300 series from Rotork YTC is a high-performance electro-pneumatic smart valve positioner widely applied in industries such as petrochemical, power, pharmaceuticals, and process automation. It receives a 4-20 mA analog current signal from PLC or DCS, processes it through a built-in PID controller, and converts it into a pneumatic signal to precisely drive valve actuators. The unit also supports HART communication and optional feedback output (4-20 mA or digital) for closed-loop control.

This article explains its operating principle, core functions, product features, selection criteria, and usage guidelines in detail.

1. Working Principle

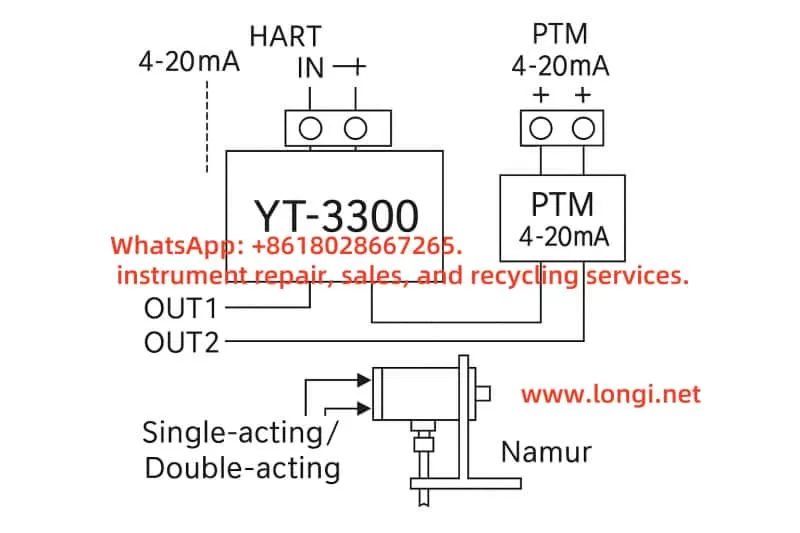

The YT-3300 receives a 4-20 mA signal (HART optional) representing the desired valve position. An internal 12-bit ADC samples the current and compares it to the actual valve position measured by an integrated travel sensor (either a magnetic resistance sensor or potentiometer). The PID controller calculates the necessary correction.

The output is then handled by an internal I/P (current-to-pressure) converter using a nozzle-flapper mechanism and miniature solenoid valves. The result is two precisely controlled pneumatic outputs (OUT1 / OUT2), used to actuate single- or double-acting pneumatic actuators.

The travel sensor’s reading can also be converted to a 4-20 mA signal or a digital communication protocol (e.g., HART, FF, PA) for remote monitoring.

2. Block Diagram (Closed-loop control)

4-20 mA Input ─┐

▼

+------------------------------+

| PID Controller + PWM Driver |

+------------------------------+

│ ▲

▼ │

Miniature I/P Valve │ Travel Sensor

│ │ (NCS / Potentiometer)

▼ │

OUT1 / OUT2 Pneumatic Output

│

▼

Pneumatic Actuator (Single/Double)

3. Key Functions

- Digital PID Control: High-precision positioning within ±0.5% F.S.

- Auto Calibration: AUTO1 / AUTO2 scan modes for fast commissioning.

- Split Range Support: 4–12 mA / 12–20 mA assignment.

- Feedback Options: 4-20 mA feedback (PTM module), mechanical limit switch (LSi), HART/FF/PA digital output.

- Self-Diagnosis: Error codes such as OVER CUR, RNG ERR, or C ERR displayed on LCD screen.

- Manual/Auto Switch: Supports bypass operations during maintenance.

4. Product Features

- Integrated PID + I/P + feedback + diagnostics in one unit.

- Compatible with both linear and rotary actuators.

- IP66/NEMA 4X enclosure with explosion-proof or intrinsically safe options.

- Supports SIL2/3 safety systems.

- Maintenance-free NCS sensor and remote sensor options for high-temp or vibration zones.

5. Model Selection Guide

| Code Position | Option | Description |

|---|---|---|

| 1 | L / R | Linear or Rotary Actuator |

| 2 | S / D | Single or Double Acting |

| 3 | N / i / A / E | No Explosion / Intrinsically Safe |

| 4 | 0 / 2 / F / P | None / HART / FF / PA Communication |

| 5 | 1 / 2 / … | PTM (Feedback) / LSi (Limit Switch) |

Examples:

YT-3300RDN1101S: Rotary, double acting, no feedback, no HART.YT-3300LSi-1201S: Linear, single acting, with 4-20 mA feedback + limit switch.

6. Installation & Usage

Mechanical:

- Ensure linkage lever aligns perpendicular at 50% stroke.

- Use Namur bracket for rotary actuator mounting.

Pneumatics:

- Use clean, dry air (0.14–0.7 MPa); OUT1 for single-acting, both OUT1/OUT2 for double-acting.

Electrical:

- IN+ to signal source; IN– to common.

- PTM feedback must use a separate loop.

Calibration:

- Hold [MODE] to enter AUTO1.

- Recalibrate using AUTO2 if positioning errors > 5%.

- Adjust PID or Deadzone if valve hunts or is sluggish.

7. Common Faults

| Code | Description | Fix |

|---|---|---|

| OVER CUR | Input > 24 mA | Check wiring, short circuit |

| RNG ERR | Stroke out of range | Recalibrate or adjust lever |

| C ERR | Control deviation too big | Check air supply, valve jam |

8. Application Scenarios

- Control valves in chemical reactors

- LNG valve control under sub-zero conditions

- SIL-rated ESD valve systems

- Remote installations requiring non-contact sensors

9. Conclusion

The YT-3300 series combines intelligent PID control, precise I/P conversion, diagnostics, and multiple feedback options into one robust, compact unit. Its flexibility in communication (analog or digital), safety compliance, and rugged design make it a superior choice for modern valve automation.