1. Introduction

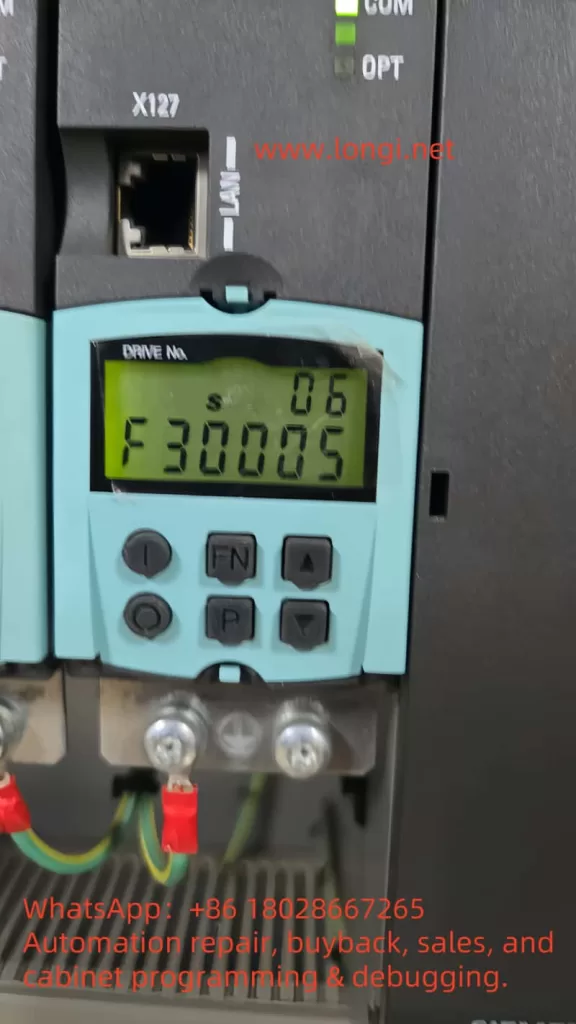

The Siemens SINAMICS S120 series drive system is widely used in multi-axis control, high-dynamic-response, and high-precision industrial applications. However, during operation, users may occasionally encounter the F30005 – Power Unit Overload (I²t Overload) fault.

Once this fault occurs, the drive immediately shuts down the output of the affected power module, causing a production stop. This article combines official manual diagrams, fault descriptions, and real-world cases to provide a systematic analysis of the fault and offer practical solutions.

2. Definition and Trigger Conditions of F30005

In the SINAMICS S120, thermal protection of the power unit is not only based on temperature sensors but also on an I²t model for thermal load calculation.

- Principle of the I²t Model

- I represents current, t represents time.

- The system calculates the thermal accumulation in the power unit based on current magnitude and duration.

- When thermal accumulation exceeds the threshold (

r0036 = 100%), F30005 is triggered.

- Trigger Conditions (based on the manual & logic diagram)

- Power unit current exceeds rated value for too long.

- Insufficient cooling intervals between load cycles.

- Load cycle mismatch, resulting in sustained high load.

- Power unit or motor is undersized for the actual load.

3. Difference Between F30005 and Other Thermal Faults

According to the manual, the S120’s power unit thermal monitoring generates several alarm/fault codes:

| Fault Code | Description | Detection Method |

|---|---|---|

| F30004 | Inverter heatsink overtemperature | Direct temperature sensor |

| F30025/F30026 | Chip or electronics module overtemperature | Chip temperature sensor |

| F30005 | Power unit I²t overload | Current-time integration model |

| F30007 | Rectifier overtemperature | Rectifier temperature sensor |

Key difference:

- Overtemperature faults (e.g., F30004) are triggered instantly by high physical temperature readings.

- F30005 is based on accumulated thermal load — it can occur even if the instantaneous temperature is moderate, as long as the sustained current is too high.

4. Signal Flow and Internal Logic

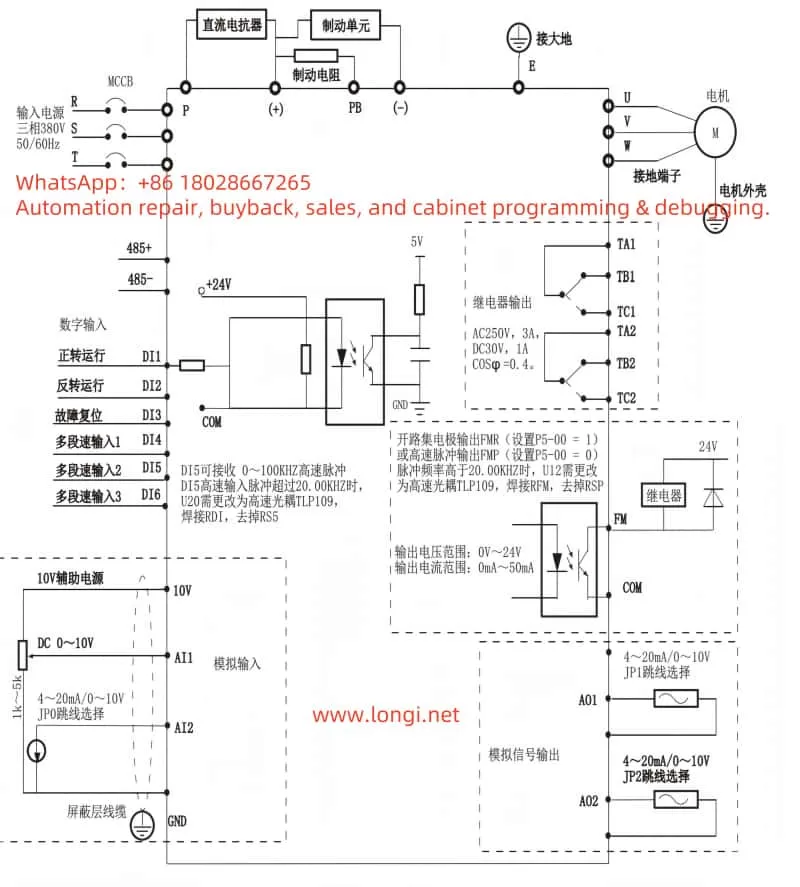

From the provided manual diagram, the F30005 trigger logic is as follows:

- Measure actual absolute current (

I_act_abs_value). - Feed the value into the I²t model, along with rated power unit current (

r0207). - Calculate power unit load percentage (

r0036). - If

r0036 ≥ 100%, trigger the “Power Unit Overload” signal. - The control unit issues the F30005 fault and shuts down the module output (Shutdown Type: 2).

5. Common Causes in Practice

- Excessive mechanical load

- Jammed mechanism, high friction, bearing failure, misalignment.

- Improper drive settings

- Acceleration/deceleration times too short, frequent start/stop cycles.

- Improper torque or speed limit settings.

- Undersized drive module

- Rated current too low for the real load.

- Poor cooling or high ambient temperature

- Inadequate cabinet ventilation, ambient temperature > 40°C.

- Load cycle mismatch

- Frequent high peak loads without adequate cooling periods.

6. Corrective and Preventive Actions

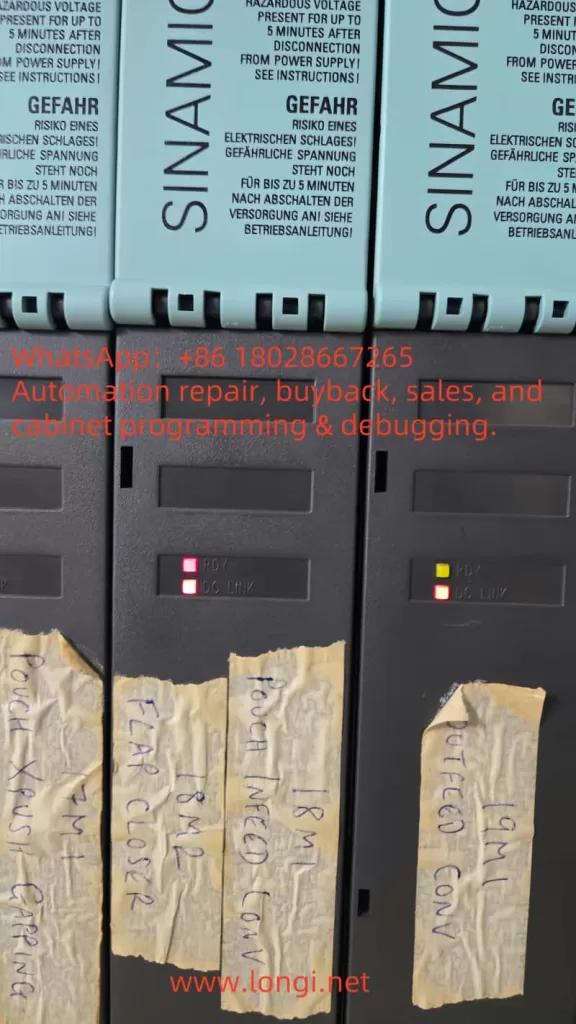

1) Immediate on-site actions

- Stop and cool: Switch off power, wait for DC LINK capacitors to discharge (>5 minutes), allow the unit to cool.

- Reset: Clear the fault via the operator panel or control system, and observe if it reoccurs.

2) Medium-term corrective measures

- Reduce load current

- Check lubrication, bearing condition, mechanical alignment.

- Reduce process load or adjust production cycle.

- Optimize parameters

- Increase acceleration/deceleration times (

p1120/p1121). - Lower maximum torque limit (

p1520).

- Increase acceleration/deceleration times (

- Improve cooling

- Increase cabinet airflow.

- Clean fan filters and check fan operation.

3) Long-term optimization

- Proper sizing: Replace the Motor Module with a higher current rating if load is consistently near/exceeding nominal current.

- Load cycle adjustment: Ensure intervals between high-load cycles for cooling.

- Monitoring and early warning: Use

r0036monitoring — trigger an early warning at 80% load before fault occurs.

7. Key Parameters and Diagnostic Tools

- Important monitoring parameters

r0036: Power unit I²t load % (0–100%).r0206: Power unit rated power.p0307: Motor rated power.

- Diagnostic software

- Use STARTER or TIA Portal to connect to the CU control unit.

- Check diagnostic buffer for current/load curves before the fault.

8. Conclusion

F30005 “Power Unit I²t Overload” is not just a simple overtemperature issue — it is the result of current and time acting together. It reflects both the mechanical load conditions and the appropriateness of drive sizing and operating strategy.

By understanding the fault mechanism, monitoring key parameters, and applying both immediate and long-term corrective actions, users can significantly reduce the frequency of F30005 faults and ensure stable, efficient operation of the SINAMICS S120 system.

Flowchart – F30005 Fault Trigger Logic & Troubleshooting Steps

┌──────────────────────────────────┐

│ Measure Actual Current (I) │

└──────────────────────────────────┘

│

▼

┌──────────────────────────────────┐

│ Calculate Thermal Load via I²t │

│ Model (r0036 %) │

└──────────────────────────────────┘

│

┌──────────────┴──────────────┐

│ │

r0036 < 100% r0036 ≥ 100%

│ │

▼ ▼

Continue Operation ┌─────────────────────┐

│ Trigger F30005 │

│ Shutdown Output │

└─────────────────────┘

│

▼

┌────────────────────────────────┐

│ On-site Actions: │

│ 1. Stop & Cool Down │

│ 2. Reset Fault │

└────────────────────────────────┘

│

▼

┌─────────────────────────────────────┐

│ Fault Cleared? │

└─────────────────────────────────────┘

│ │

Yes No

│ │

▼ ▼

┌─────────────────────────┐ ┌─────────────────────────┐

│ Monitor r0036 trend & │ │ Inspect mechanical load, │

│ optimize parameters │ │ cooling, and sizing; │

└─────────────────────────┘ │ replace module if needed │

└─────────────────────────┘