I. Control Panel Operations and Parameter Management

1. Panel Interface Fundamentals

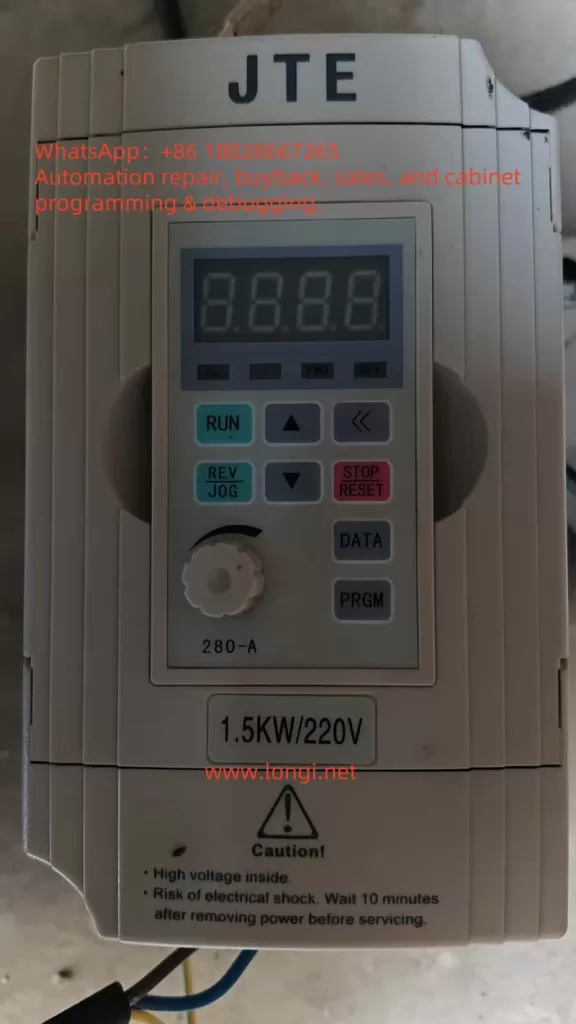

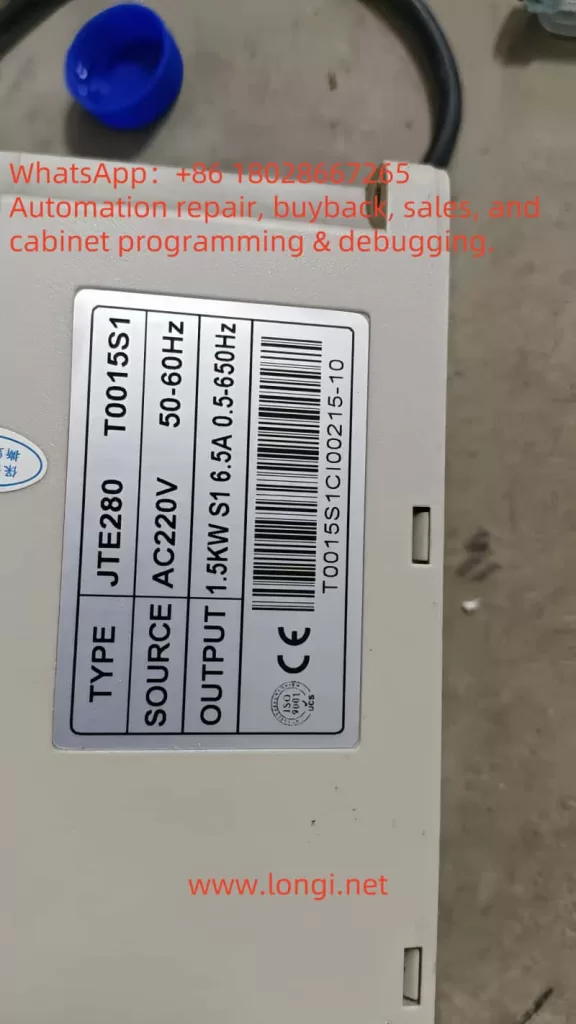

The JTE280 features two panel configurations (Fig.4-1/4-2) with essential controls:

RUN: Start operation (requires P0.03=0)REV/JOG: Reverse/Jog (configured via P3.52)STOP/RESET: Halt/Reset faultsPRGM: Access parameters (5-sec hold locks keyboard)▲/▼: Adjust values (real-time speed adjustment)<<: Toggle monitoring parameters (J-00~J-11)

2. Factory Reset Procedure

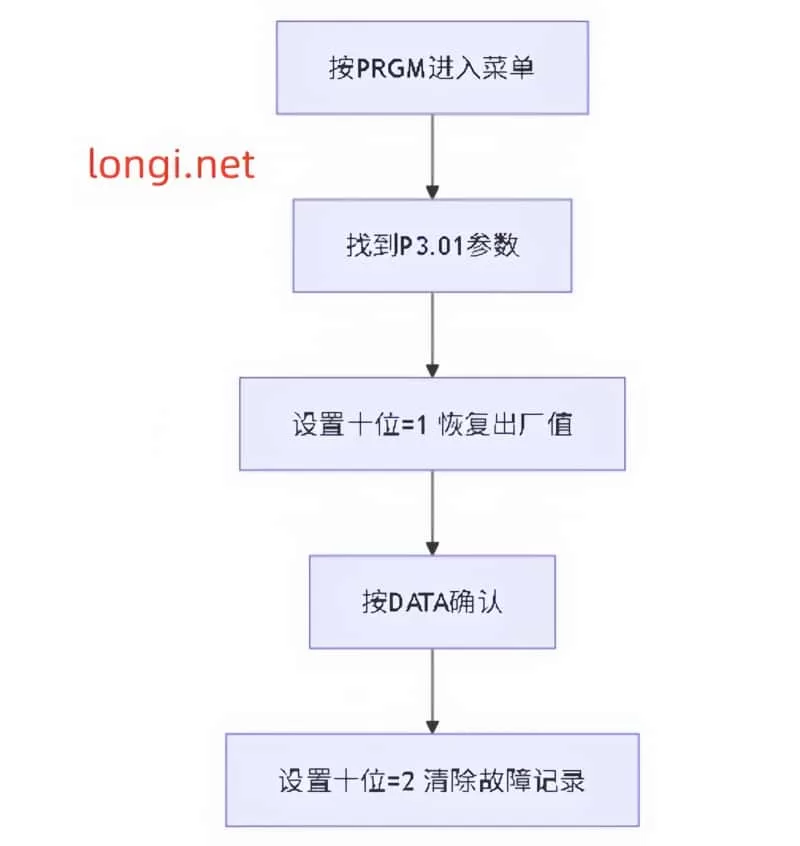

Execute through hierarchical menu:

graph TD

A[Press PRGM] --> B[Locate P3.01]

B --> C[Set tens-digit=1 for default]

C --> D[Confirm with DATA]

D --> E[Set tens-digit=2 to clear faults]3. Security Configuration

- Password Protection: Set P0.00 (0001-9999)

- Access Levels (P3.01 units-digit):

0: Full access1: Only P3.01 adjustable2: Only P0.02+P3.01 adjustable- Keyboard Lock: 5-sec

PRGMhold

II. External Control Implementation

1. Terminal-Based Motor Control

Critical Parameters:

P0.03 = 1 ; Terminal control mode

P4.08 = 0 ; 2-wire control scheme 1Wiring Specification:

- Forward: FWD-DCM short

- Reverse: REV-DCM short

- Stop: Open circuit

2. External Potentiometer Configuration

Parameter Chain:

P0.01 = 0 ; Potentiometer mode

P1.01 = 1.00 ; VI gain default

P1.02 = 0.00V ; Min voltage

P1.05 = 50.00Hz; Max frequencyConnection Protocol:

- Potentiometer wiper → VI terminal

- Potentiometer V+ → +10V terminal

- Potentiometer V- → ACM terminal

Recommended: 10kΩ linear potentiometer

III. Fault Diagnosis Matrix

| Code | Description | Root Causes | Corrective Actions |

|---|---|---|---|

| E-01 | Acceleration OC | Load surge/short acc.time | Increase P0.17, inspect mechanics |

| E-02 | Deceleration OC | Regenerative energy | Enable P5.02 overvoltage stall |

| E-11 | DC Bus UnderV | Input <305V | Verify supply, set P5.07=1 |

| E-12 | DC Bus OverV | Rapid deceleration | Adjust braking parameters |

| E-15 | IGBT Overheat | Cooling failure | Clean vents, reduce loading |

Troubleshooting Flow:

- Resolve hardware issues

- Press

STOP/RESETto clear - Analyze history (P6.00-P6.11)

IV. Advanced Application Techniques

1. Multi-Speed Programming

P4.00=1 # M11=Speed-bit1

P4.01=2 # M12=Speed-bit2

# Speed1: M11 ON

# Speed2: M12 ON

# Speed3: M11+M12 ON2. Winding Control (Textile Applications)

P9.00=1 ; Enable wobble

P9.04=10.0% ; Amplitude

P9.06=5.0s ; Cycle time3. PID Pressure Regulation

P7.00=1 ; Enable PID

P7.10=0.85 ; Proportional gain

P7.16=25.00 ; Preset frequency

Key Operational Notes:

- High-altitude (>1000m) requires derating (Fig.1-3)

- Long cables (>30m) mandate output reactors (Sec.1.3.8)

- Braking resistors must comply with Table 3-25 specifications

This guide synthesizes critical operational knowledge from the 117-page manual. For complete technical specifications, refer to Chapter 9 (Application Examples) and Appendix (MODBUS protocols). Proper implementation of these procedures will optimize drive performance while ensuring operational safety.