— Practical Application of DriveExecutive Software with USB-DSI Adapter

1. Introduction

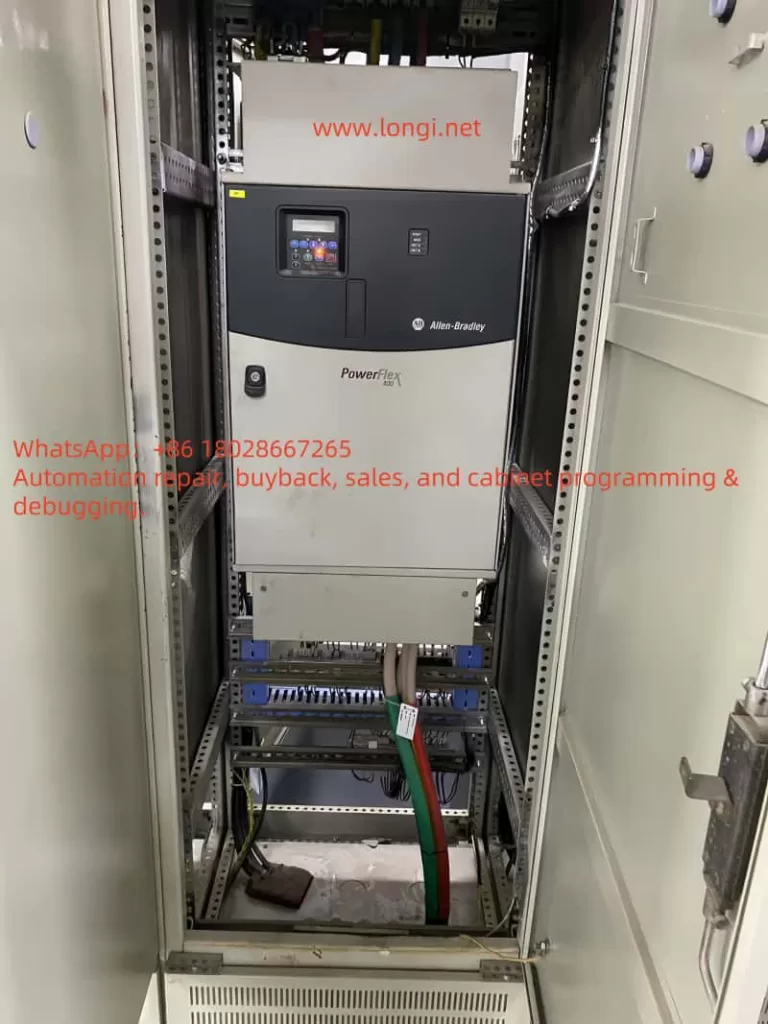

In the field of industrial automation, variable frequency drives (VFDs) play a central role in motor control and energy efficiency. Among them, the Allen-Bradley PowerFlex family from Rockwell Automation is widely recognized for its reliability, flexibility, and robust communication options.

This article focuses on the PowerFlex 400 drive (e.g., Cat No. 22C-D142A103) and demonstrates how to use DriveExecutive software together with a USB-to-DSI communication adapter to perform parameter diagnostics, upload/download operations, and fault analysis. By combining hardware setup, software configuration, and troubleshooting techniques, this guide provides a complete workflow for engineers working in the field.

2. Overview of the PowerFlex 400

The PowerFlex 400 is a VFD designed specifically for fan and pump applications. Its main characteristics include:

- Voltage class: 380–480V three-phase input;

- Power range: from 3 kW to 250 kW, with the case in this article being 75 kW (100 HP);

- Built-in communication: standard RS485 (DSI) port, expandable to Modbus, EtherNet/IP, DeviceNet, and others;

- Application features: optimized PID control for HVAC and pumping systems, built-in bypass logic, and energy-saving functions.

3. Diagnostic Needs in the Field

Typical on-site requirements for engineers include:

- Reading and backing up all drive parameters;

- Monitoring real-time operating data such as voltage, current, frequency, and load;

- Modifying parameters for control mode tuning or PID loop optimization;

- Accessing fault and alarm history for troubleshooting.

To accomplish these tasks efficiently, a reliable PC-based diagnostic tool is essential. The combination of DriveExecutive software and a USB-to-DSI adapter is one of the most recommended solutions.

4. Required Hardware and Software

Hardware

- PowerFlex 400 VFD (e.g., Cat No. 22C-D142A103);

- USB-to-DSI communication adapter (1203-USB is the official Rockwell option; third-party compatible adapters may also work);

- A Windows PC or laptop;

- Proper cabling (USB to PC, DSI end to the drive’s RS485 port).

Software

- RSLinx Classic: Rockwell’s official communication driver software, required for all connections;

- DriveExecutive: the parameter management and diagnostic tool used to interact with the drive.

5. Step-by-Step Connection Procedure

1. Physical Connection

- Plug the USB-to-DSI adapter into the PC;

- Connect the other end of the adapter to the PowerFlex 400’s DSI port (typically marked R+, R-, COM);

- Ensure the drive is powered on.

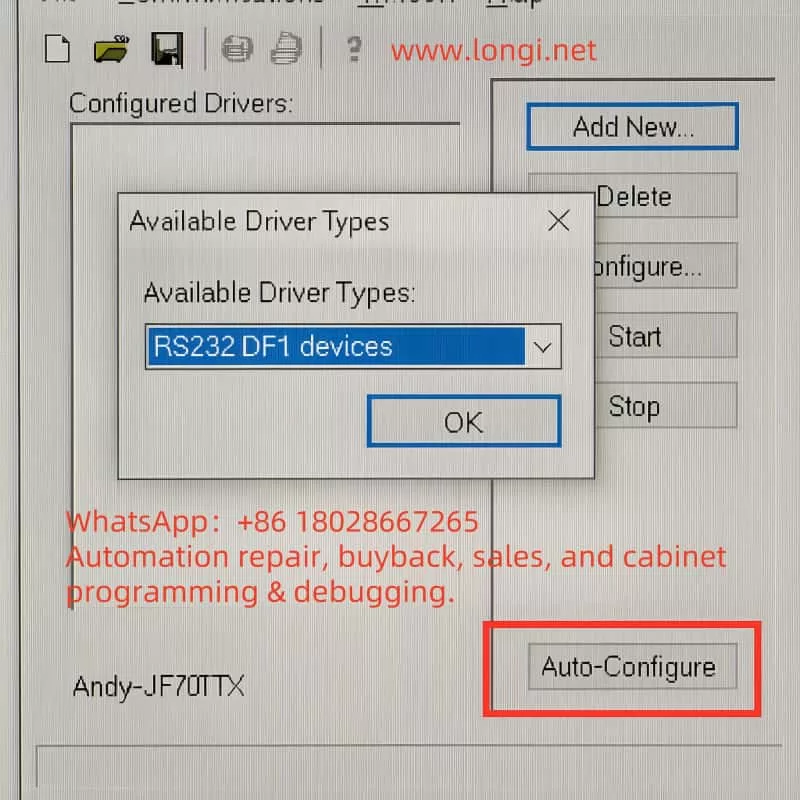

2. Configuring RSLinx Classic

- Open RSLinx Classic;

- Navigate to Communications → Configure Drivers…;

- Add a new driver:

- For the original 1203-USB: choose USB-DF1 Devices;

- For third-party USB-RS485 adapters: choose RS232 DF1 Devices;

- Select the correct COM port for the adapter;

- Click Auto-Configure. If the message “Successfully configured” appears, communication is established.

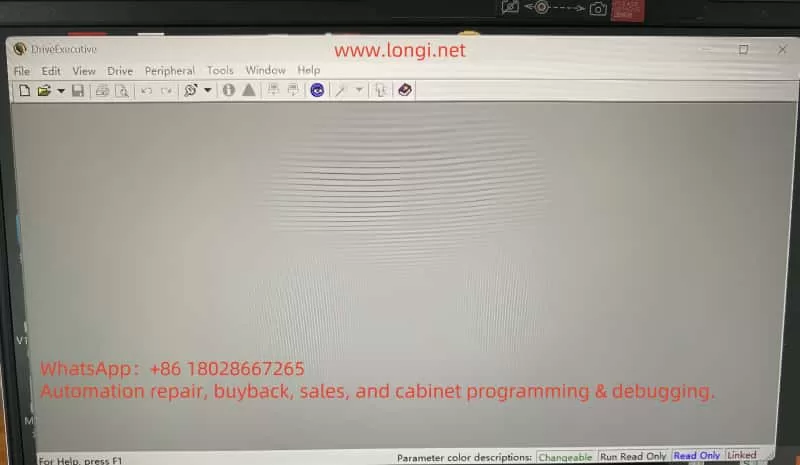

3. Connecting with DriveExecutive

- Launch DriveExecutive;

- From the menu, select Drive → Connect;

- Choose RSLinx as the communication path;

- Browse for the device and locate PowerFlex 400 [Node Address];

- Click to connect and enter the parameter view.

6. Troubleshooting Common Issues

- Adapter not recognized

- Ensure the USB driver for the adapter is installed;

- Check Windows Device Manager to confirm the virtual COM port is created.

- Auto-Configure fails

- Verify proper wiring to the DSI port, paying attention to polarity of R+ and R-;

- Ensure the baud rate matches the default setting (typically 19.2 kbps).

- DriveExecutive cannot detect the drive

- Confirm that RSLinx RSWho can see the drive node;

- If visible in RSLinx but not in DriveExecutive, refresh the communication path or check software licensing.

- Unstable third-party adapter

- Some non-official adapters may cause unreliable communication. For critical or long-term use, the official 1203-USB adapter is strongly recommended.

7. Practical Applications and Benefits

With the setup described above, engineers can perform the following tasks effectively:

- Parameter upload and download: simplifying commissioning and backup;

- Real-time monitoring: displaying drive data such as current, output frequency, and DC bus voltage;

- Fault diagnostics: quickly identifying root causes by reviewing alarm and fault logs;

- Remote support: when paired with VPN or remote desktop tools, parameter diagnostics can be carried out off-site, minimizing downtime.

In large-scale pump stations and building automation systems, this workflow greatly improves efficiency and reliability in maintenance operations.

8. Conclusion

The PowerFlex 400 is a well-established drive optimized for fan and pump loads. In practice, engineers often need to back up, monitor, and adjust parameters while troubleshooting on-site. By combining DriveExecutive software, RSLinx Classic, and a USB-to-DSI adapter, a comprehensive solution for diagnostics and communication is achieved.

For occasional parameter access, third-party USB-RS485 cables may suffice. However, for professional and long-term industrial use, the official 1203-USB adapter ensures maximum stability and compatibility.

As industrial systems evolve toward Ethernet-based communication (EtherNet/IP), USB-to-DSI solutions may gradually be phased out. Nevertheless, given the large installed base of PowerFlex 400 and similar models, this approach remains highly practical and relevant in today’s fieldwork.