Introduction

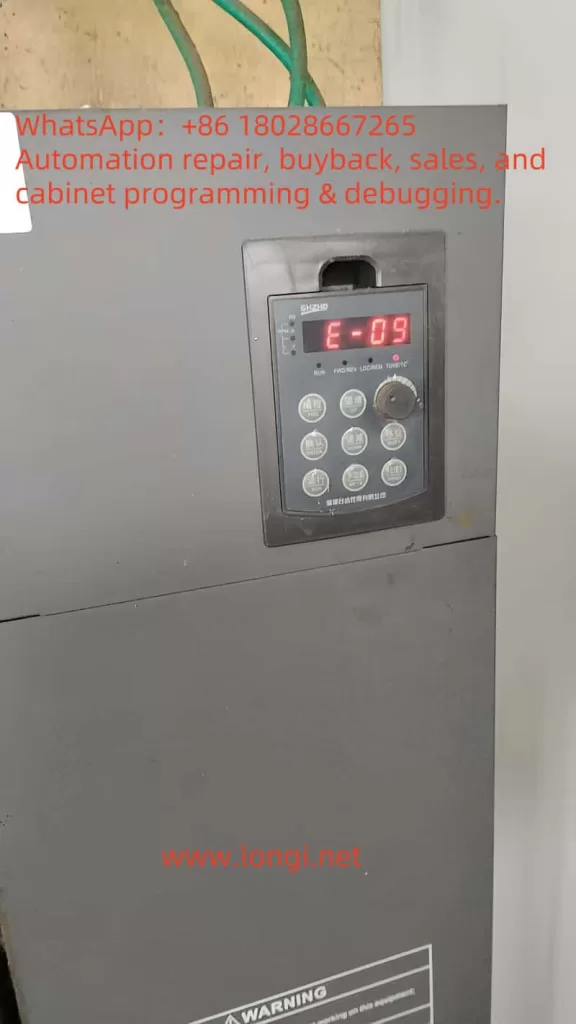

Variable frequency drives (VFDs) are critical components in industrial automation, enabling precise control of motor speed and torque to enhance efficiency and performance. The V680 series VFD, produced by Shenzhen Tai Da Holdings, is a high-performance model widely used in applications such as manufacturing, HVAC systems, and conveyor operations. However, like all sophisticated electronic devices, it may encounter faults that disrupt operations. One common issue is the “E-09” fault code, which indicates an undervoltage condition. This article provides a comprehensive analysis of the E-09 fault’s mechanisms, implications, diagnostic procedures, solutions, and preventive strategies, drawing from technical insights and industry resources.

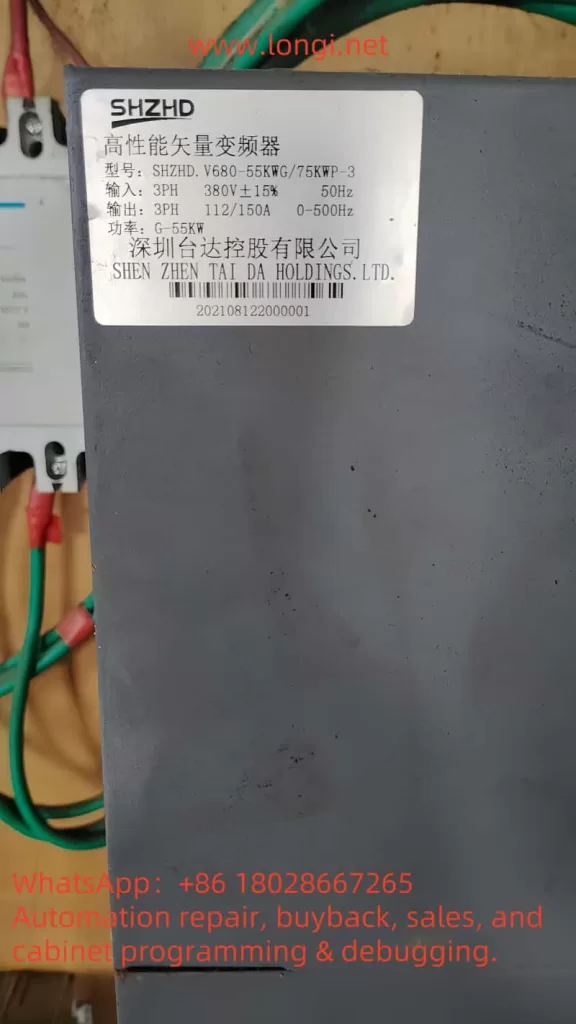

Technical Background of the V680 Series VFD

Role of VFDs

VFDs regulate the speed and torque of AC motors by adjusting the frequency and voltage of the power supplied. This capability optimizes energy consumption, reduces mechanical stress, and enhances process control in industrial settings. The V680 series, with its advanced vector control algorithms, is designed for demanding applications requiring high reliability and precision.

V680 Series Specifications

Based on available information, the V680 series (model: SHZHD.V680-55KW/75KWP-3) has the following key specifications:

| Parameter | Specification |

|---|---|

| Input | 3-phase, 380V ±15%, 50Hz |

| Output | 3-phase, 112/150A, 0-500Hz |

| Power | G-55kW |

| Manufacturer | Shenzhen Tai Da Holdings Co., Ltd. |

The input voltage range of 323V to 437V is critical for understanding the E-09 fault, as voltages below 323V trigger undervoltage protection.

Definition and Implications of the E-09 Undervoltage Fault

Definition

The E-09 fault code signifies that the VFD’s input voltage has fallen below the minimum threshold required for safe operation, typically around 323V for a 380V system. This undervoltage condition prompts the VFD to halt operation to protect itself and the connected motor, displaying “E-09” on the control panel.

Implications

The E-09 fault can have significant consequences:

- Operational Downtime: The VFD’s shutdown halts motor operation, disrupting production processes and potentially causing financial losses in industries reliant on continuous operation.

- Component Wear: Prolonged undervoltage can stress electrolytic capacitors and other components, reducing their lifespan and increasing maintenance costs.

- Performance Issues: In applications requiring precise motor control, such as conveyor systems, undervoltage may lead to erratic motor behavior, compromising product quality.

Mechanisms Behind the E-09 Undervoltage Fault

VFD Operational Principles

A VFD converts input AC power to DC through a rectifier, stores it in a DC bus with capacitors, and then inverts it back to AC with adjustable frequency and voltage to drive the motor. The DC bus voltage, typically around 520V for a 380V input, is crucial for stable operation. A drop in input voltage reduces the DC bus voltage, triggering the E-09 fault if it falls below the undervoltage threshold (approximately 60% of nominal, or ~312V DC).

Causes of Undervoltage

The E-09 fault may result from several factors:

- External Power Supply Instability:

- Grid Fluctuations: Variations in the utility power supply, such as voltage sags or outages, can lower the input voltage.

- Heavy Load Demands: Simultaneous operation of high-power equipment may cause voltage drops.

- Phase Loss: Loss of one phase in a three-phase system increases DC bus ripple and may trigger undervoltage protection.

- Internal Component Failures:

- Capacitor Degradation: Electrolytic capacitors in the DC bus may lose capacity over time, failing to smooth voltage fluctuations.

- Rectifier Issues: Damaged diodes or rectifiers in the power conversion circuit can impair voltage regulation.

- Pre-Charge Circuit Problems: Faulty pre-charge relays or resistors can prevent proper DC bus charging, especially during startup.

- Wiring and Connection Issues:

- Loose or corroded connections increase resistance, causing voltage drops at the VFD’s input.

- Improper wiring, as outlined in the V680 manual’s connection diagrams, can exacerbate the issue.

- Environmental Factors:

- High temperatures or humidity can degrade component performance, indirectly contributing to undervoltage.

- Dust accumulation may cause overheating or short circuits, affecting voltage stability.

- Sensing Circuit Malfunction:

- A faulty DC voltage sensing circuit within the VFD may incorrectly detect low voltage, causing nuisance trips.

Trigger Mechanism

The VFD continuously monitors the DC bus voltage. When it detects a voltage below the undervoltage threshold, it activates the E-09 fault, halting operation. For the V680 series, this threshold is likely set to protect against voltages below 323V AC, corresponding to a DC bus voltage of approximately 312V. The fault may reset automatically after 5 seconds if the voltage stabilizes, as noted in some Tai Da VFD documentation.

Diagnostic Steps for the E-09 Fault

Diagnosing the E-09 fault requires a systematic approach to identify the root cause:

- Verify Input Voltage:

- Measure the input voltage at the VFD’s terminals using a multimeter, ensuring it is within 380V ±15% (323V–437V).

- Check all three phases for balance and absence of phase loss.

- If the voltage is low, investigate upstream power supply issues with the utility provider.

- Inspect Internal Components:

- Power down the VFD and inspect for visible signs of damage, such as capacitor leakage, bulging, or burn marks on the rectifier or control board.

- Test capacitors and rectifiers with appropriate equipment, if qualified, or consult a technician.

- Check the pre-charge circuit for relay or resistor functionality.

- Examine Wiring and Connections:

- Refer to the V680 manual’s wiring diagrams to verify correct connections.

- Tighten all terminal connections and inspect cables for damage or corrosion.

- Evaluate Environmental Conditions:

- Ensure the VFD operates within the recommended temperature (-10°C to +40°C) and humidity (≤95% RH, non-condensing) ranges.

- Clean dust from the VFD and improve ventilation if necessary.

- Review Control Panel Diagnostics:

- Note any additional indicators on the control panel, such as “Hz” or “RUN” status, to contextualize the fault.

- Cross-reference the E-09 code with the manual’s fault table, if available, for specific guidance.

- Test DC Bus Voltage:

- If equipped, measure the DC bus voltage to confirm it aligns with the expected value (~520V for 380V input). Discrepancies may indicate internal issues or sensing circuit faults.

Solutions to Resolve the E-09 Undervoltage Fault

Immediate Corrective Actions

- Reset the Fault:

- Power cycle the VFD by turning off the main supply, waiting a few minutes, and restarting. Alternatively, use the control panel’s reset function.

- Verify if the fault clears after voltage stabilization.

- Address Power Supply Issues:

- Install a voltage stabilizer or uninterruptible power supply (UPS) to maintain consistent 380V input.

- Use a line reactor or isolation transformer to mitigate voltage sags and surges.

- Coordinate with the utility provider to adjust transformer tap settings or resolve grid issues.

- Repair Internal Components:

- Replace faulty capacitors, rectifiers, or pre-charge circuit components, adhering to the manual’s maintenance guidelines and using manufacturer-approved parts.

- Engage a qualified technician for complex repairs to avoid further damage.

- Correct Wiring Issues:

- Tighten loose connections and replace damaged cables as per the manual’s wiring specifications.

- Ensure proper grounding to prevent electrical interference.

- Mitigate Environmental Factors:

- Relocate the VFD to a cooler, drier location or enhance ventilation with fans or air conditioning.

- Install dust filters to protect internal components.

Long-Term Preventive Measures

- Regular Maintenance:

- Schedule monthly or quarterly inspections to check wiring, components, and cleanliness, as recommended in the V680 manual.

- Monitor capacitor health and replace them proactively based on their rated lifespan.

- Power Protection Systems:

- Deploy surge protectors, phase loss relays, and dynamic voltage restorers to safeguard against power anomalies.

- Consider a static var compensator for facilities with frequent voltage sags.

- Environmental Optimization:

- Maintain a controlled environment with stable temperature and humidity levels.

- Enclose the VFD in a protective cabinet if exposed to harsh conditions.

- Operator Training:

- Train personnel to recognize E-09 and other fault codes, enabling quick initial responses.

- Provide access to the V680 manual for reference during troubleshooting.

- Manufacturer Support:

- Establish a relationship with Shenzhen Tai Da Holdings’ customer service for technical support and access to firmware updates or replacement parts.

Comparison with Other VFD Faults

To contextualize the E-09 fault, consider other common VFD faults:

| Fault Code | Description | Common Causes |

|---|---|---|

| E-10 | Overvoltage | Excessive input voltage, regenerative energy |

| E-06 | Overcurrent | Motor overload, short circuit |

| E-04 | Overheating | Poor ventilation, high ambient temperature |

| E-07 | Ground Fault | Motor or wiring insulation failure |

While E-09 is specific to undervoltage, its diagnostic and resolution strategies overlap with these faults, particularly in checking power supply and environmental conditions.

Additional Insights from Industry Resources

Research indicates that undervoltage faults, like E-09, are common in VFDs due to their sensitivity to power quality. , undervoltage protection is typically based on DC bus voltage, which for a 380V system should be around 520V. A drop to 60% of this value (~312V) triggers the fault. The site also highlights phase loss as a frequent cause.

Troubleshooting Flowchart

Below is a simplified flowchart for addressing the E-09 fault:

Start

↓

Check Input Voltage (380V ±15%)

↓

Voltage Normal? → Yes → Inspect Internal Components

↓ No

Adjust Power Supply (Stabilizer/UPS)

↓

Fault Cleared? → Yes → End

↓ No

Inspect Wiring/Connections

↓

Connections Secure? → Yes → Check Environment

↓ No

Tighten/Replace Wiring

↓

Environment Normal? → Yes → Reset Fault

↓ No

Improve Ventilation/Cleanliness

↓

Fault Cleared? → Yes → End

↓ No

Contact Manufacturer Support

Conclusion and Best Practices

The E-09 undervoltage fault in the V680 series VFD is a manageable issue when approached systematically. By identifying whether the cause is external power instability, internal component failure, wiring issues, or environmental factors, users can implement targeted solutions to restore operation. The V680 manual is a critical resource, providing wiring diagrams, safety guidelines, and maintenance protocols to support troubleshooting.

Best practices include:

- Stable Power Supply: Use voltage stabilizers and UPS systems to ensure consistent 380V input.

- Routine Maintenance: Conduct regular inspections to detect and address component wear early.

- Environmental Control: Maintain optimal operating conditions to protect the VFD.

- Operator Training: Equip staff with the knowledge to respond to fault codes promptly.

- Manufacturer Support: Leverage Shenzhen Tai Da Holdings’ expertise for complex issues.

By adopting these strategies, users can minimize downtime, extend the VFD’s lifespan, and ensure reliable performance in industrial applications. This comprehensive approach not only resolves the E-09 fault but also enhances overall system resilience against future power-related issues.