Introduction

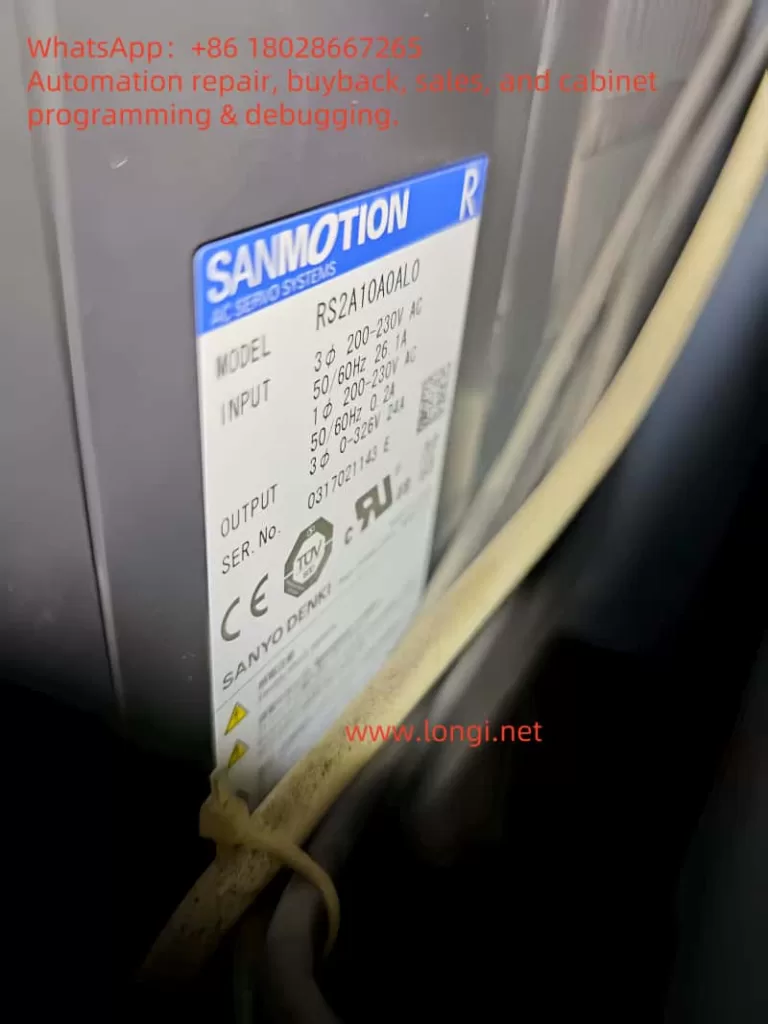

Sanyo Denki’s SanMotion RS2 series servo drivers are renowned for their precision and reliability in industrial automation applications, such as robotics, CNC machines, and automated manufacturing systems. These drivers are designed to deliver high-performance motion control, but like any sophisticated electronic system, they can encounter faults that disrupt operations. One such fault is the AL.72.8 error code, which, based on available information, likely indicates a ±12V power supply abnormality. This fault can halt critical operations, making it essential for technicians and engineers to understand its causes, troubleshooting steps, and preventive measures. This article provides a comprehensive guide to diagnosing and resolving the AL.72.8 fault, ensuring minimal downtime and sustained system performance.

Understanding the AL.72.8 Fault Code

The AL.72.8 fault code, sometimes displayed as “72H” in hexadecimal format, is believed to indicate an abnormality in the ±12V power supply within the Sanyo Denki SanMotion RS2 series servo driver. The ±12V supply is a critical component that powers various control circuits, including:

- Encoder Interfaces: For precise motor position feedback.

- Communication Ports: Such as RS-485 or CANopen, used for interfacing with control systems.

- Logic Circuits: For processing control signals and ensuring proper operation.

When the ±12V supply deviates from its nominal range (typically ±12V ±10%) or fails entirely, it can lead to erratic behavior, loss of control, or complete system shutdown. The fault is displayed prominently on the driver’s digital panel, as observed in user-provided images, signaling the need for immediate troubleshooting.

Potential Causes of AL.72.8

Several factors can trigger the AL.72.8 fault. Understanding these causes is the first step toward effective resolution:

- Internal Power Supply Failure:

- The servo driver relies on an internal DC-DC converter to generate the ±12V supply from the main AC input (typically 200-240V AC). Failures in this converter, due to component wear, overheating, or manufacturing defects, can result in unstable or absent ±12V output.

- Symptoms may include intermittent faults, random resets, or loss of communication with the motor or controller.

- Short Circuit or Open Circuit:

- A short circuit in the ±12V line can cause excessive current draw, triggering protective circuits or damaging components.

- An open circuit, conversely, prevents voltage from reaching critical components, leading to operational failures.

- Damaged Components:

- Components on the control board, such as operational amplifiers, logic ICs, or microcontrollers powered by the ±12V supply, may fail due to overvoltage, overheating, or prolonged use.

- Visual signs include burnt, discolored, or swollen components, particularly electrolytic capacitors.

- Incorrect Wiring:

- While the ±12V supply is typically internal, external modifications or incorrect wiring during maintenance can introduce faults.

- Unauthorized changes or loose connections can disrupt the power supply chain.

- Main Power Supply Issues:

- The main AC input voltage must remain within 200-240V AC (±10%) for proper operation. Fluctuations, spikes, or sags can stress the internal DC-DC converter, affecting the ±12V supply.

- Phase imbalances or power quality issues can exacerbate this problem.

- Aging Components:

- Electrolytic capacitors, commonly used in power supply circuits, degrade over time, losing capacitance or increasing equivalent series resistance (ESR). This can destabilize the ±12V supply, especially under load.

- Other components, such as voltage regulators, may also deteriorate with prolonged use.

The following table summarizes the potential causes and their impacts:

| Cause | Potential Impact |

|---|---|

| Internal Power Supply Failure | Unstable or missing ±12V supply, system shutdown |

| Short Circuit/Open Circuit | Excessive current or no voltage to circuits |

| Damaged Components | Abnormal voltage behavior, circuit failure |

| Incorrect Wiring | Disrupted power supply, erratic operation |

| Main Power Supply Issues | Stress on internal converter, voltage instability |

| Aging Components | Reduced performance, intermittent faults |

Troubleshooting the AL.72.8 Fault

Resolving the AL.72.8 fault requires a systematic approach to identify and address the root cause. Below are detailed troubleshooting steps:

- Verify Main Power Supply:

- Use a true RMS multimeter to measure the input AC voltage at the driver’s power terminals, ensuring it is within 200-240V AC (±10%).

- Check for voltage stability using a power quality analyzer if fluctuations are suspected.

- Ensure the power source is free from phase imbalances or excessive noise.

- Inspect Internal and External Wiring:

- With the power off and proper safety precautions (e.g., wearing ESD-safe gear), open the servo driver.

- Visually inspect internal wiring for loose connections, burnt wires, or signs of overheating.

- Check external connections, such as those to the motor or controller, for damage or improper wiring.

- Measure ±12V Supply:

- Locate the ±12V test points on the control board, as specified in the RS2 series service manual.

- With the driver powered on (in a safe, servo-off state), measure the voltage using a multimeter. The reading should be close to ±12V with minimal ripple (<1% of nominal voltage).

- If the voltage is out of range, trace the ±12V lines to identify the point of failure.

- Check for Short Circuits:

- Disconnect the driver from power.

- Use a multimeter in continuity mode to check for shorts between the ±12V lines and ground or other circuits.

- Measure resistance across the ±12V lines; it should be high (open circuit) unless intentional loads are present.

- Inspect Components:

- Examine the control board for visible damage, such as bulging capacitors, discolored resistors, or burnt ICs.

- If possible, measure the resistance or capacitance of suspect components and compare with expected values.

- Use Diagnostic Tools:

- Utilize Sanyo Denki’s SANMOTION R Setup Software to access fault logs and additional error codes.

- Monitor parameters related to power supply status to gain further insight into the fault.

- Consult Manufacturer’s Documentation:

- Refer to the RS2 series manual for specific troubleshooting flowcharts or procedures for AL.72.8.

- Check for service bulletins or known issues related to this fault code.

- Contact Technical Support:

- If the issue persists, contact Sanyo Denki’s technical support or an authorized service center. Provide the model number, serial number, fault code, and detailed observations from your troubleshooting efforts.

- Support contact details include:

The following table outlines the troubleshooting steps and their objectives:

| Step | Objective |

|---|---|

| Verify Main Power Supply | Ensure input voltage is within specifications |

| Inspect Wiring | Identify loose or damaged connections |

| Measure ±12V Supply | Confirm voltage stability and range |

| Check for Short Circuits | Detect electrical faults in ±12V lines |

| Inspect Components | Identify damaged or faulty components |

| Use Diagnostic Tools | Access detailed fault logs and parameters |

| Consult Documentation | Follow manufacturer’s troubleshooting guide |

| Contact Technical Support | Obtain expert assistance for unresolved issues |

Preventive Measures

Preventing the AL.72.8 fault and similar issues requires proactive maintenance and careful system design. Here are key preventive measures:

- Regular Maintenance:

- Schedule inspections every 6-12 months, depending on the operating environment.

- Clean the driver to remove dust and debris, which can cause overheating or electrical issues.

- Replace aging components, such as electrolytic capacitors, as per the manufacturer’s maintenance schedule.

- Stable Power Supply:

- Install voltage stabilizers or uninterruptible power supply (UPS) systems to protect against power fluctuations.

- Ensure the electrical panel includes overcurrent protection and surge suppression devices.

- Proper Installation:

- Mount the servo driver vertically to optimize cooling and ensure adequate airflow.

- Install in a clean, dry, and well-ventilated environment to prevent overheating and contamination.

- Monitor System Performance:

- Use the driver’s built-in monitoring functions or diagnostic software to log temperatures, voltages, and other parameters.

- Set up alerts for abnormal conditions, such as voltage deviations or temperature increases.

- Training and Documentation:

- Train maintenance personnel on the specific RS2 series model and its fault codes.

- Maintain up-to-date documentation, including service manuals and wiring diagrams, for quick reference.

Conclusion

The AL.72.8 fault code in Sanyo Denki SanMotion RS2 series servo drivers likely indicates a ±12V power supply abnormality, which can disrupt critical control functions. Potential causes include internal power supply failures, short circuits, damaged components, or main power supply issues. By following a systematic troubleshooting approach—verifying the main power supply, inspecting wiring, measuring voltages, and consulting technical support—technicians can effectively diagnose and resolve the issue. Preventive measures, such as regular maintenance, stable power supply, and proper installation, are essential for minimizing the occurrence of this fault and ensuring the longevity of the servo system. For further assistance, refer to the official Sanyo Denki documentation or contact their technical support team.