FANUC servo drives, specifically the βISVSP A06B series, are widely used in various automated equipment, providing efficient and precise motor control. However, in practical use, various faults may arise, with one of the most common being the lack of display. A non-functional display is often caused by power issues, control circuit problems, or hardware malfunctions. This article explores the maintenance approach for resolving no display issues in FANUC servo drives, focusing on troubleshooting steps and solutions.

I. Fault Phenomenon: No Display

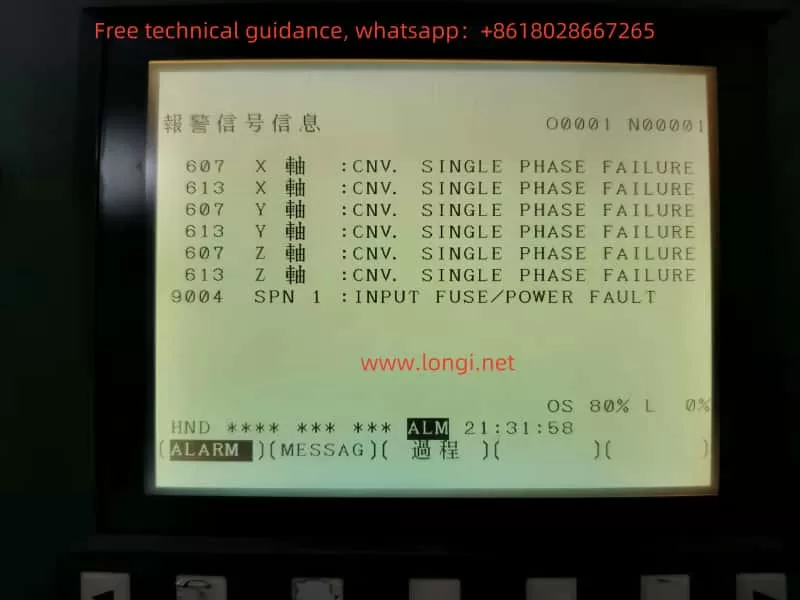

The no display fault in FANUC servo drives refers to a situation where the device powers on, but the panel displays no information. The indicator lights might be completely off, or the screen may be unresponsive, suggesting that there could be problems with the control circuits, display module, or power supply module inside the drive. If not addressed in a timely manner, this issue could prevent the device from starting or executing control instructions, which can negatively impact production efficiency.

II. Troubleshooting Approach

When encountering a no display issue in a servo drive, it’s essential to systematically check the device. Below are the common troubleshooting steps:

1. Check Power Supply Input

The first step is to verify if the power supply to the servo drive is functioning correctly. Power is the foundation for all electronic devices, and any instability or interruption in the power supply can prevent the drive from functioning properly.

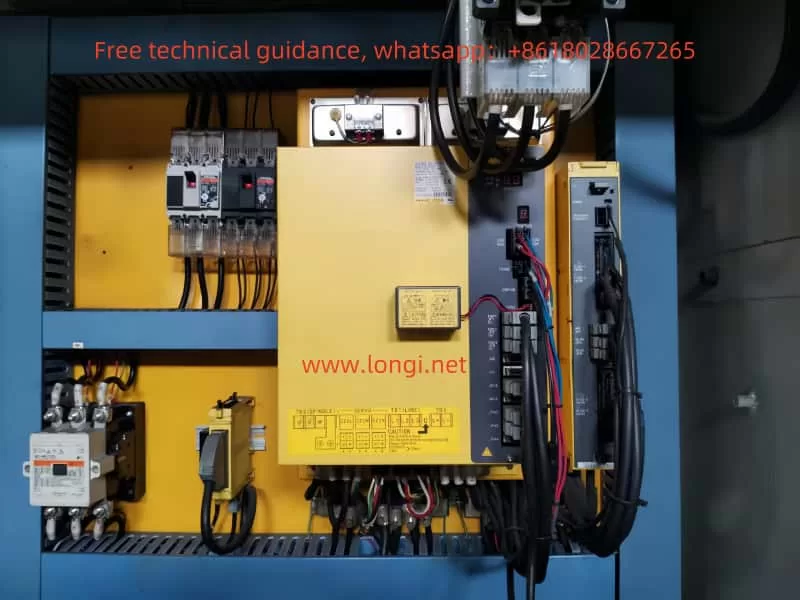

- Check the Power Voltage: Use a multimeter to check the voltage at the input terminals of the servo drive, confirming that it falls within the specified range. The FANUC servo drive typically requires a three-phase AC input voltage within a certain range.

- Check Power Connections: Verify that the power supply cables are correctly connected and not damaged or disconnected. Poor power contact can lead to unstable voltage supply, which can result in no display issues.

2. Check Fuses and Circuit Breakers

Servo drives are equipped with fuses or circuit breakers to prevent damage from excessive current. If a fuse blows or the circuit breaker trips, the device will fail to operate properly.

- Check the Fuse: Open the servo drive and inspect the fuses in the power section. If the fuse is blown, replace it with one of the same rating.

- Check the Circuit Breaker: Some servo drives come with an internal circuit breaker that trips in case of voltage abnormalities or overcurrent. If the circuit breaker has tripped, reset it manually.

3. Check the Main Control Circuit

If the power supply is fine, the next step is to inspect the servo drive’s main control circuit. The control circuit acts as the brain of the servo drive, and any malfunction in this area could result in a non-responsive display.

- Check the Control Chip: The control chip is usually located centrally on the circuit board and is responsible for processing input signals and controlling the operation of the drive. Look for signs of overheating, burning, or damage around the chip. Use an oscilloscope or multimeter to check the power supply voltage and signal output of the chip to ensure it’s functioning properly.

- Check Circuit Connections: The circuit board in the servo drive is connected to various modules via connectors. Check if any connectors are loose or disconnected, as poor connections can prevent signals from transmitting correctly.

4. Check the Display Module and Signal Transmission

The display module is responsible for showing system status information to the operator. If the display module fails, it could lead to a no display situation.

- Check the Display Screen: Inspect the power supply input terminals and signal transmission lines to the display screen to ensure they are properly connected. If the display module itself is faulty, it may need to be replaced.

- Check Signal Transmission: If the display module appears intact, the issue could lie with the signal transmission. Inspect the signal lines between the main control board and the display module to ensure that signals are properly transmitted.

5. Check Capacitors and Power Filtering Circuits

Capacitors and filtering circuits help stabilize the voltage supply, especially for high-frequency currents. If the capacitors are damaged, the power supply could become unstable, affecting the drive’s operation.

- Check the Capacitors: Look for signs of bulging, leakage, or aging in the capacitors. If a capacitor is faulty, it should be replaced with one of the same model.

- Check the Filtering Circuits: The components in the filtering circuits may also be damaged, which can cause unstable voltage output. Inspect these components and replace them as necessary.

III. Common Fault Analysis and Solutions

1. Unstable Power Supply Leading to No Display

An unstable power supply voltage can prevent the drive from starting properly. In this case, check the stability of the power supply and ensure the voltage is within the specified range. If issues are found with the power supply, it may be necessary to replace the power module or reconnect the power supply.

2. Control Circuit Malfunction

A malfunctioning control circuit can prevent the system from starting or lead to a no display issue. Typically, this fault requires replacing damaged components. Commonly damaged components include control chips, integrated circuits, and resistors.

3. Display Module Failure

If the display module itself is faulty, it could be due to issues with the backlight, circuit board, or the display screen. Inspect the power input terminals and signal transmission lines to confirm the issue. If the display screen is damaged, replacing the display module will likely resolve the problem.

4. Capacitor or Filtering Circuit Issues

Damaged capacitors can cause unstable power, affecting the drive’s operation. Replacing faulty capacitors or repairing the filtering circuits should solve this issue.

IV. Conclusion

The no display issue in FANUC servo drives βISVSP A06B series is typically related to power problems, control circuit failures, or display module malfunctions. Through systematic troubleshooting and careful inspection, the problem can usually be pinpointed and resolved. During maintenance, special attention should be paid to power stability, circuit connections, and the condition of critical components. For more complex issues, professional diagnostic tools may be required, and damaged components should be replaced to restore the device to normal operation. Timely and effective maintenance ensures the long-term stability and performance of FANUC servo drives, helping to maintain production efficiency.