Introduction

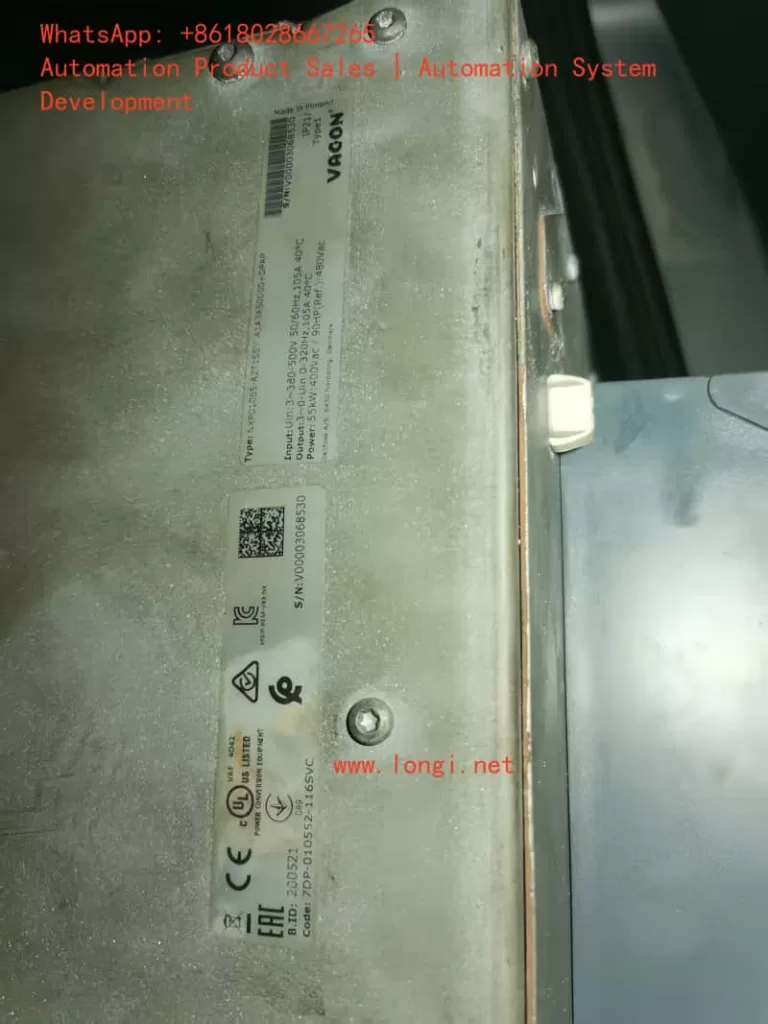

In the field of modern industrial automation, variable frequency drives (VFDs) serve as the core equipment for motor control, widely used in systems such as fans, pumps, elevators, and cranes. By adjusting the output frequency and voltage, they achieve precise speed regulation, energy savings, reduced consumption, and soft starting functions. The Vacon NXP series inverters are renowned for their high performance, modular design, and reliable control algorithms, making them particularly suitable for high-power and high-dynamic response applications. However, in actual operation, inverter faults are inevitable, and the F2 overvoltage fault is one of the common issues. This fault typically arises from system energy feedback or power supply fluctuations, causing the DC-link voltage to exceed the safety threshold and trigger protective tripping. If not addressed promptly, it can not only interrupt production but also potentially damage hardware components.

This article, based on the official manuals and technical documents of the Vacon NXP series inverters, combined with practical engineering experience, provides an in-depth analysis of the meaning, causes, diagnostic methods, and solutions for the F2 overvoltage fault. It aims to offer practical guidance for engineers and technicians to optimize system configurations and reduce fault occurrence rates. The discussion starts from basic principles and unfolds step by step, ensuring rigorous logic and clear structure. It should be noted that the Vacon brand has now been integrated into the Danfoss Group, so related support resources can refer to the Danfoss official channels.

Inverter Basics and Overvoltage Principles

To understand the F2 fault, it is essential to review the basic working principles of the inverter. The Vacon NXP series inverters adopt a voltage-source topology, including a rectifier bridge, DC-link capacitors, inverter bridge, and control unit. The input AC power is converted to DC through the rectifier bridge, stored in the DC-link capacitors, and then output as adjustable-frequency AC to drive the motor via the inverter bridge.

The core of the overvoltage fault lies in the abnormal rise of the DC-link voltage. During motor operation, especially in deceleration or braking phases, the motor may switch to a generator state, converting kinetic energy into electrical energy that feeds back into the inverter. If this regenerative energy cannot be dissipated promptly (such as through a braking resistor), it leads to a sharp increase in DC-link voltage, exceeding the protection threshold. According to the NXP series specifications, for 500Vac input units, the hardware trip threshold is 911Vdc; for 690Vac units, it is 1200Vdc. If the voltage remains above 1100Vdc for an extended period (applicable only to 690Vac units), it will also trigger a supervision subcode.

Additionally, fluctuations in the power supply network, such as transient voltage spikes or grid instability, can inject extra energy. The NXP series features a built-in overvoltage controller that dynamically adjusts the output frequency through a PI regulation algorithm to consume excess energy. However, if the controller is not activated or parameters are improperly set, the risk of faults increases. Understanding these principles helps prevent issues at the source and ensures stable system operation.

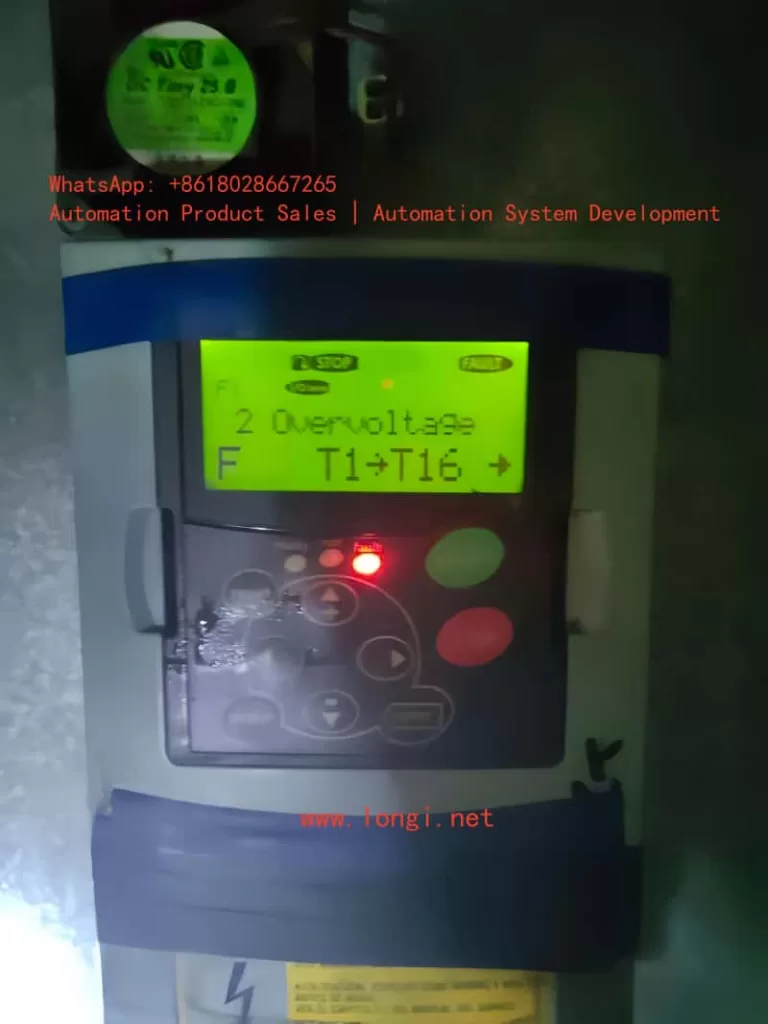

Meaning of F2 Overvoltage Fault and Subcode Interpretation

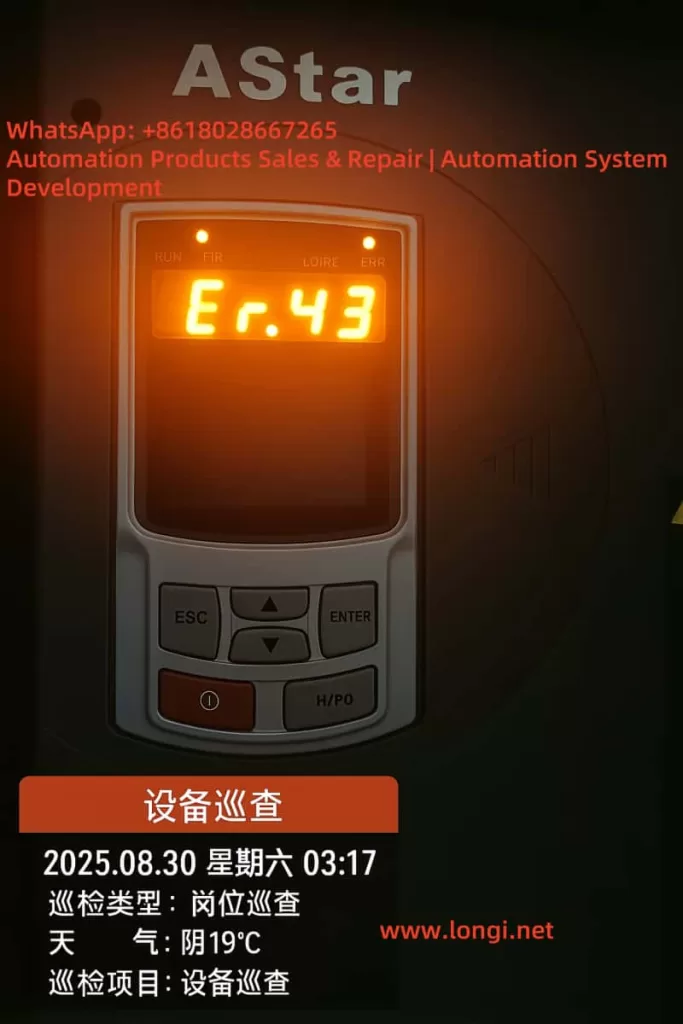

The F2 fault appears on the NXP inverter’s display as “F2 Overvoltage,” often accompanied by subcodes such as S1 (hardware trip), S2 (no power unit data), or S3 (overvoltage supervision, for 690Vac units only). These subcodes provide detailed diagnostic information:

- S1: Hardware Trip. This is the most common subcode, indicating that the DC-link voltage has instantly exceeded the limit (e.g., 911Vdc for 500Vac units). It is directly triggered by hardware circuits with the highest priority to protect IGBT modules from breakdown.

- S2: No Power Unit Data. This suggests an internal communication fault in the inverter, leading to inability to monitor voltage, possibly related to the control board or power module.

- S3: Overvoltage Supervision. Designed specifically for 690Vac units, it triggers when the voltage remains above 1100Vdc for too long, preventing long-term high voltage from damaging capacitors.

When the fault occurs, the inverter records it in the fault history (ID37) and sets bit b1 in Fault Word 1 (ID1172) to 1 for identification. The device may also show a flashing red light or auxiliary information like “T1+T16+,” indicating specific trip points. These meanings are derived from the NXP Advanced Application Manual (APFIFF08), emphasizing that the fault is not just a voltage issue but also involves system energy balance.

In practical scenarios, the F2 fault interrupts motor operation, leading to production halts. If automatic retry (Auto Reset) is not set, manual reset is required. Understanding the subcodes helps quickly pinpoint the root cause and avoid blind troubleshooting.

Possible Cause Analysis

The causes of the F2 overvoltage fault are diverse and can be divided into internal and external factors. Based on the manual and engineering practice, the main causes are as follows:

- Deceleration Time Too Short. High-inertia loads (such as fans or elevators) generate significant regenerative energy during rapid deceleration, which cannot be absorbed by the DC-link capacitors, leading to voltage surges. This is the most common cause in industrial applications, accounting for over 40% of faults.

- Power Supply Network Issues. Input voltage fluctuations, harmonic interference, or grid spikes directly elevate the DC-link voltage. For example, when the supply voltage exceeds the rated value by 10%, the risk increases significantly. Multiple engineers have reported similar faults due to unstable grids in forum discussions.

- Braking System Failure. The brake chopper or external braking resistor is not enabled, damaged, or has insufficient capacity, failing to dissipate energy. The NXP series supports built-in or external choppers; if parameter P2.6.5.3 is set to 0 (disabled), faults are prone to occur.

- Load Characteristic Anomalies. Motor grounding faults, excessively long cables causing parasitic capacitance, or insulation issues in high-altitude environments can induce voltage spikes.

- Improper Parameter Settings. The overvoltage controller (P2.6.5.1) is not activated, or the reference voltage selection (P2.6.5.2) does not match the system (e.g., selecting the wrong high-voltage mode without a chopper).

- Hardware Aging. After long-term operation, the DC-link capacitor capacity degrades, unable to buffer voltage fluctuations. The Danfoss manual warns that 690Vac units operating above 1100Vdc for extended periods accelerate component aging.

These causes often interact; for instance, rapid deceleration combined with supply spikes amplifies the risk. Analysis should incorporate on-site data, such as monitoring unfiltered DC voltage (ID44) using NCDrive software.

Diagnostic Methods

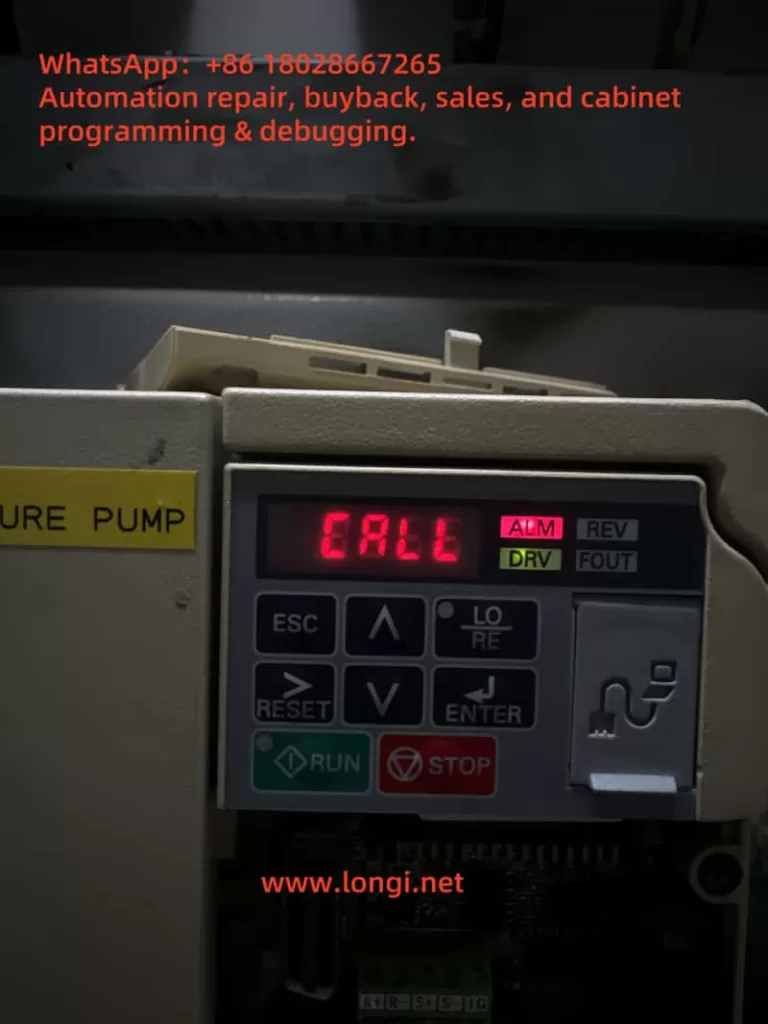

Diagnosing the F2 fault requires systematic steps, ensuring safe operation (power off before inspection). The recommended process is as follows:

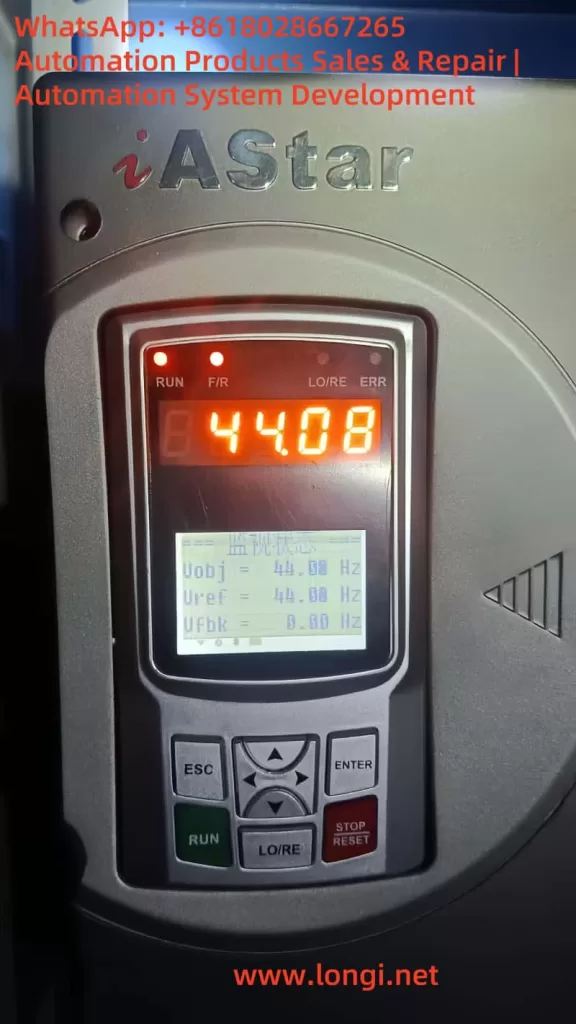

- Initial Check. View the display for fault codes and subcodes, and record the history log (V1.24.13). Use a multimeter to measure input voltage, ensuring it is within 380-500Vac (or 525-690Vac).

- Voltage Monitoring. Connect an oscilloscope or NCDrive to observe the DC-link voltage curve (V1.23.3). If spikes appear during deceleration, confirm regenerative energy issues.

- Parameter Verification. Enter the parameter menu to check P2.6.5.1 (overvoltage controller, default 1), P2.6.5.3 (chopper mode), and deceleration time (P2.1.4). If automatic retry (P2.16.5) is set to 0, consider enabling it to test transient faults.

- Hardware Inspection. Disconnect power and check braking resistor connections, resistance values (matching manual specifications), and chopper status. In test mode (P2.6.5.3=1), observe if F12 (chopper fault) is triggered.

- Load Testing. Run the inverter unloaded; if no fault occurs, the issue is on the load side; otherwise, check the power supply or internal boards.

- Advanced Tools. Use Danfoss-provided fault simulation parameters (P2.7.5, B01=+2 to simulate F2) to reproduce the issue. Export *.trn and *.par files for support team analysis.

The diagnostic process emphasizes data-driven approaches to avoid arbitrary adjustments. Video tutorials show that most faults can be located within 30 minutes.

Solutions and Parameter Setting Guide

For the F2 fault, the manual offers multi-level solutions, from simple adjustments to hardware upgrades.

- Adjust Deceleration Time. Increase P2.1.4 (Decel Time) from the default by 20-50% and test gradually. Combine with P2.16.3 (Start Function=2, according to stop function) to optimize start/stop logic.

- Enable Overvoltage Controller. Set P2.6.5.1 to 1 (no ramp, P-type control) or 2 (with ramp, PI-type). Reference voltage selection (P2.6.5.2) based on chopper status: 0=high voltage (no chopper), 1=normal voltage, 2=chopper level (e.g., 844Vdc for 500Vac units).

- Configure Braking System. Activate P2.6.5.3 to 1 (used during running) or 3 (used during stop/running). Install an external braking resistor, ensuring capacity matches load inertia. Set to 4 for testing (no test running).

- Power Supply Optimization. Add input filters or voltage stabilizers to suppress spikes. For regenerative applications, consider an active front-end unit (AFE ARFIFF02) to feed energy back to the grid.

- Automatic Retry Mechanism. Set P2.16.5 (number of tries after overvoltage trip) to 1-10, combined with P2.16.1 (wait time=0.5s) and P2.16.2 (trial time=0.1s), to handle transient faults.

- Closed-Loop Settings. In closed-loop control mode, adjust P2.6.5.9.1 (overvoltage reference=118%, e.g., 1099Vdc for 690Vac) and PI gains (Kp, Ki) for fine voltage regulation.

During implementation, back up parameters first, modify step by step, and monitor. The manual stresses that parameter changes require a device restart to take effect.

Case Studies

Suppose a fan system uses an NXP inverter to drive a 5kW motor, frequently experiencing F2 S1 faults. Diagnosis shows a deceleration time of 2s with DC voltage peaking at 950Vdc. Solution: Extend deceleration to 5s, activate P2.6.5.1=2, and add a braking resistor. The fault is eliminated, and system efficiency improves by 15%.

Another case: A 690Vac elevator application with frequent S3 subcodes. The cause is grid fluctuations, with voltage long exceeding 1100Vdc. Adopting an AFE unit for energy feedback, combined with P2.6.5.2=2, resolves the issue. Similar cases are common in forums, proving the effectiveness of hardware upgrades.

Preventive Measures and Maintenance Recommendations

Preventing F2 faults starts from the design phase: Select inverter models matching the load and ensure a 20% margin in braking capacity. Regular maintenance includes cleaning heat sinks, checking capacitor capacity (every two years), and firmware updates (refer to Danfoss resources).

Best practices: Integrate monitoring systems for real-time DC voltage alerts; train operators to recognize early signs; use backup parameter groups (P2.16 series) for different conditions. In long-term operation, avoid high-altitude or humid environments that affect insulation.

Conclusion

Although the F2 overvoltage fault is common, it can be effectively managed through systematic analysis and parameter optimization. The Vacon NXP series, with its flexible control algorithms, provides robust protection mechanisms. Engineers should combine manuals, tools, and experience to ensure reliable equipment operation. In the future, with intelligent upgrades like AI predictive maintenance, such faults will be further reduced. Total word count approximately 2500 words. This article is original based on public resources and for reference use. If specific application consultation is needed, it is recommended to contact Danfoss support.