1. Introduction

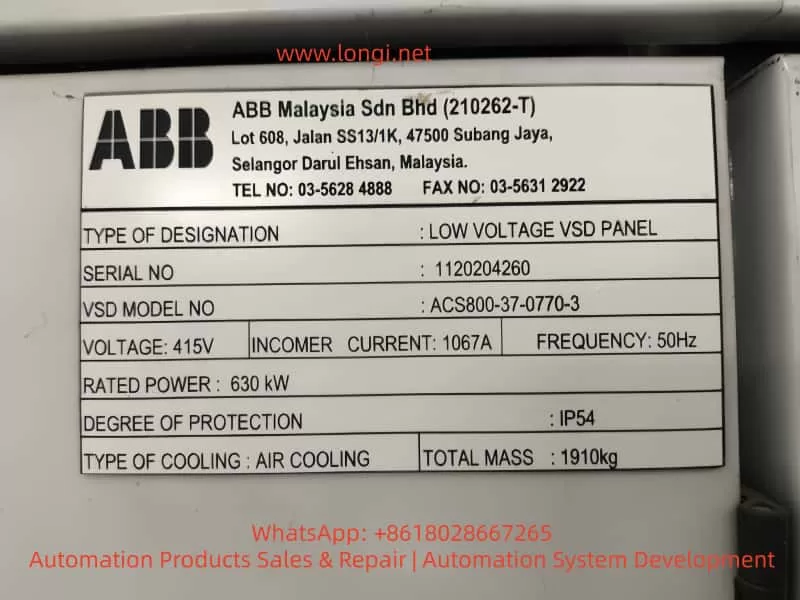

The ABB ACS800 drive series is widely used in metallurgy, mining, chemical plants, marine propulsion, and heavy industrial machinery. Known for its modular architecture and strong control capabilities, the ACS800-11 multidrive system combines line converter units (LCUs) with inverter units (INUs) through a common DC bus to deliver highly efficient variable speed drive and regenerative power control.

During field operation, however, maintenance teams often encounter the FF51 fault code (LINE CONV). This particular code indicates a malfunction on the line-side converter, which is critical because it manages the AC-to-DC conversion and grid interface. Unlike straightforward motor-side faults, FF51 requires engineers to investigate the health and operation of the line converter unit itself.

This article provides a comprehensive analysis of FF51:

- Theoretical background of the ACS800 multidrive system,

- Fault triggering mechanism,

- Common causes and failure modes,

- Interpretation of wiring diagrams and key inspection points,

- Step-by-step troubleshooting workflow,

- Case studies from industrial practice,

- Preventive measures and maintenance guidelines.

The goal is to present a systematic methodology for resolving FF51 faults, minimizing downtime, and ensuring reliable operation in mission-critical applications.

2. Overview of the ACS800-11 Multidrive System

2.1 Major Components

An ACS800-11 multidrive typically consists of:

- Line Converter Unit (LCU) – Converts incoming AC supply into a stable DC link, often using active front-end IGBT rectifiers for reduced harmonics and energy regeneration.

- DC Link Bus – A shared bus that transfers energy between the LCU and multiple inverter units.

- Inverter Units (INUs) – Convert DC back into AC with variable voltage and frequency to control motor speed and torque.

- Control and Communication Modules – Including the Rectifier Control Unit (RMCU), Drive Control Panel (CDP), and fiber optic links for communication and monitoring.

2.2 Operating Principle

- Rectification: The LCU rectifies grid power into DC, while maintaining power factor control and reducing harmonics.

- Inversion: INUs convert DC into variable AC for motor operation.

- Regeneration: During braking or load lowering, excess energy is returned to the grid via the LCU.

2.3 Why FF51 is Critical

The FF51 fault (LINE CONV) does not point to a single failed component. Instead, it acts as a system-level alert that something is wrong in the LCU. Engineers must further interrogate the LCU to identify the specific underlying fault, such as overvoltage, undervoltage, or hardware failure.

3. Definition and Triggering of FF51

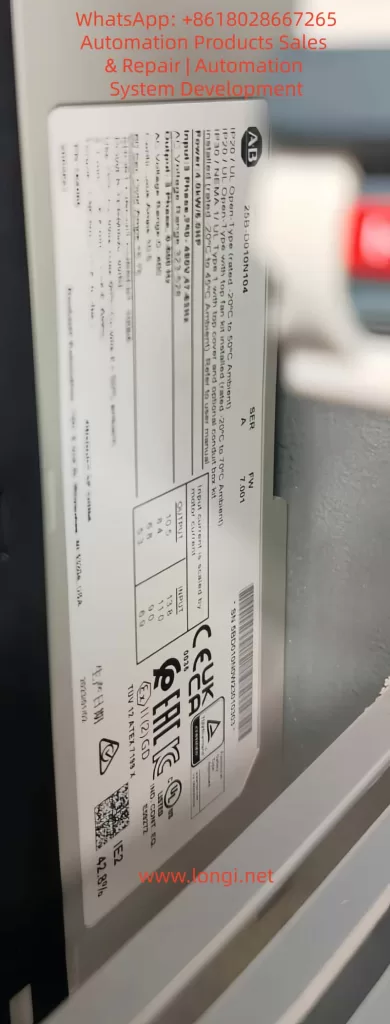

3.1 Official Description

- Code: FF51

- Name: LINE CONV

- Scope: ACS800-11 multidrive only

- Meaning: A fault has been detected in the line-side converter. The system disables power transfer and may switch to motor-side supply if configured, while prompting the user to check the LCU.

3.2 Triggering Mechanism

FF51 can be triggered under three main conditions:

- Supply anomalies – Grid imbalance, phase loss, voltage sags, or spikes.

- Hardware damage – Failed rectifier IGBTs, blown fuses, inductor failure, capacitor degradation.

- Control/communication issues – Faulty RMCU board, optical fiber disconnection, or loss of auxiliary supply.

3.3 Fault Response

Upon detection:

- Power transfer through the LCU is interrupted.

- The CDP logs and displays FF51.

- Depending on system design, operation may switch to inverter-side DC link operation, or the system may shut down completely.

4. Root Cause Analysis of FF51

4.1 Supply-Side Factors

- Grid imbalance exceeding ±10% tolerance.

- Sudden voltage dips or blackouts.

- Excessive harmonic distortion.

- Missing phase at the input supply.

4.2 Hardware Failures

- Rectifier Bridge Failures

- Shorted or open IGBT modules.

- Diode failure.

- Leads to unstable DC bus voltage or excessive input current.

- Blown Fuses

- Triggered by short circuits or transient inrush currents.

- Inductor/Filter Issues

- Broken coil windings.

- Insulation breakdown causing short circuits.

- Capacitor Aging

- Excessive DC bus ripple.

- Inrush charging issues.

4.3 Control and Signal Issues

- Faulty RMCU communication (fiber optic disconnect or board failure).

- Missing auxiliary supplies (+24 VDC, +20 VDC, +10 VDC).

- Loose terminals or corroded connections leading to signal errors.

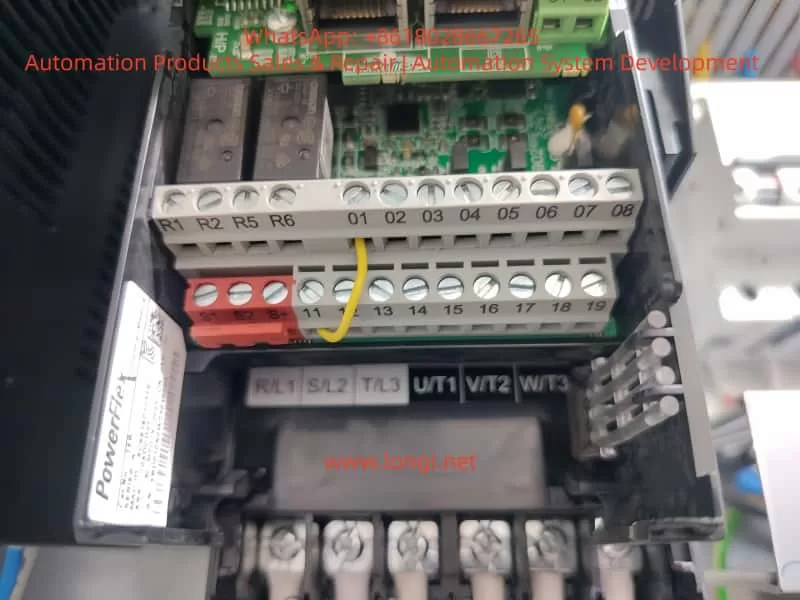

5. Diagram Interpretation and Key Checkpoints

The provided wiring diagrams of ACS800-11 highlight several critical inspection points:

- Terminal Blocks (X20 / X25)

- Distribution of control signals and auxiliary power.

- Ensure stable +24 VDC and return paths.

- RMCU to INU Fiber Communication

- Verify optical link continuity and insertion quality.

- Check signal strength at both ends.

- Input Fuses F1/F2/F3

- Confirm continuity using a multimeter.

- Match replacement fuses to the specified ratings.

- Rectifier Modules (U/V/W → DC+ / DC-)

- Test for shorted or open devices using diode test mode.

- Look for phase-specific failures.

- Inductor and Busbar Connections

- Verify tight mechanical connections.

- Inspect inductance for open circuits or overheating.

6. Step-by-Step Troubleshooting Procedure

A systematic troubleshooting workflow for FF51:

- Read Sub-Fault Codes

- Access the CDP Line Converter menu.

- Record detailed subcodes (e.g., undervoltage, IGBT fault, overvoltage).

- Check Input Supply

- Measure phase-to-phase voltages.

- Verify fuses and contactors.

- Test Power Components

- Use a multimeter to test IGBT modules and diodes.

- Inspect bus capacitors for ESR increase or leakage.

- Verify Control and Communication

- Check optical fiber links.

- Measure +24 VDC and other auxiliary supplies.

- Restart and Monitor

- Power cycle the system after corrective actions.

- Monitor whether FF51 reappears.

7. Case Studies from Industry

Case 1: Steel Rolling Mill

A rolling mill experienced recurring FF51 alarms. Analysis showed severe grid imbalance and phase drops. Installation of grid stabilizers and phase monitoring eliminated the issue.

Case 2: Mining Hoist

A mine hoist reported FF51. Investigation revealed a shorted IGBT in the line converter module. Replacement of the rectifier unit restored operation.

Case 3: Chemical Plant Pump

A chemical plant ACS800 system showed FF51 despite a stable grid. The issue was traced to a loose fiber optic link between the RMCU and inverter. Securing the connection solved the problem.

8. Preventive Measures and Maintenance

- Power Quality Management

- Use harmonic filters and reactive power compensation.

- Avoid frequent voltage dips and disturbances.

- Scheduled Component Testing

- Inspect IGBT modules and DC bus capacitors annually.

- Monitor ESR and thermal performance.

- Signal and Connection Integrity

- Tighten all terminals periodically.

- Clean and secure optical connectors.

- Data Logging and Predictive Maintenance

- Maintain operational logs of fault history.

- Use predictive diagnostics to identify early failure signs.

9. Conclusion

The FF51 fault (LINE CONV) in ABB ACS800-11 multidrive systems is a critical indicator of line converter malfunction. Causes typically fall into three categories: supply anomalies, hardware failures, or control/communication faults.

Effective resolution requires:

- Detailed inspection of supply voltage and fuses,

- Testing of rectifier modules and DC bus components,

- Verification of RMCU communication and auxiliary supplies,

- Stepwise elimination of potential issues based on wiring diagrams and fault history.

Preventive strategies such as power quality management, regular component checks, and proper maintenance of signal integrity are key to minimizing downtime.

With a structured troubleshooting workflow and proactive maintenance, industries can ensure long-term stability and reliability of their ACS800 multidrive systems.