Introduction

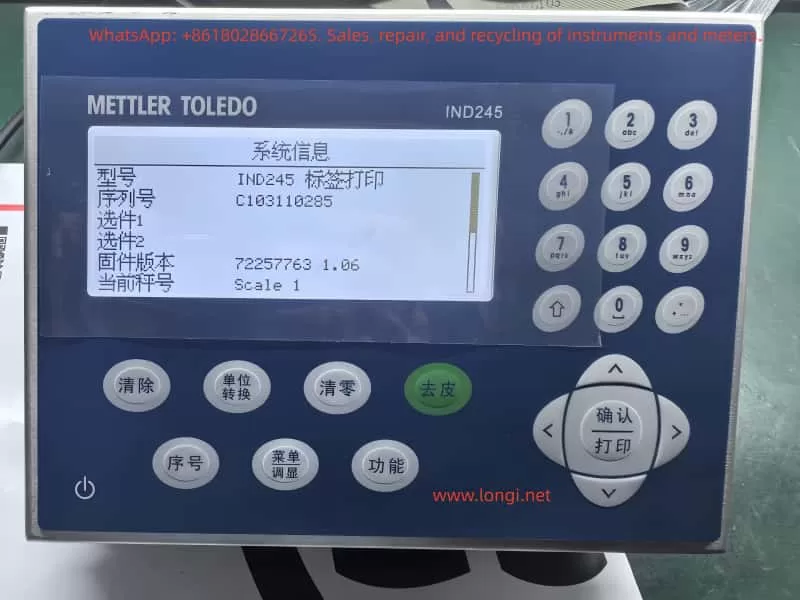

In modern industrial and commercial sectors, precise weighing is crucial for ensuring product quality, production efficiency, and fair trade. As a global leader in weighing solutions, Mettler Toledo’s IND245 Electronic Weighing Instrument (Vehicle Scale Version) stands out with its advanced technology, reliable performance, and flexible application scenarios, making it an ideal choice for vehicle weighing, logistics management, and industrial weighing. Designed specifically for vehicle scales, it supports both analog and digital sensor inputs, catering to scenarios such as truck scales and lorry weighbridges, and handling complex weighing needs from small vehicles to heavy-duty trucks.

This guide, based on the Technical Manual for the Toledo ND245 Electronic Weighing Instrument (Vehicle Scale Version), aims to provide users with a comprehensive and practical operational reference. It will start with the instrument’s principles, features, and specifications, followed by step-by-step instructions on installation and maintenance, daily operation procedures, and parameter settings, concluding with discussions on common faults and their resolution strategies. Through this guide, users will not only be able to get started quickly but also optimize instrument performance for long-term stable operation. Whether you are a first-time user or an experienced engineer, this guide will help you maximize the potential of the IND245 for efficient and accurate weighing management.

The IND245 is designed with a focus on user-friendliness and high reliability. It adopts a modular structure and supports multiple communication interfaces, suitable for a variety of applications ranging from simple weighing to complex vehicle pairing. The manual emphasizes the involvement of professionals in commissioning to avoid safety hazards. This guide will strictly adhere to the principles outlined in the manual, providing original interpretations and expanded explanations to help users apply the IND245 flexibly in real-world environments.

Instrument Principles, Features, and Specifications

Working Principles

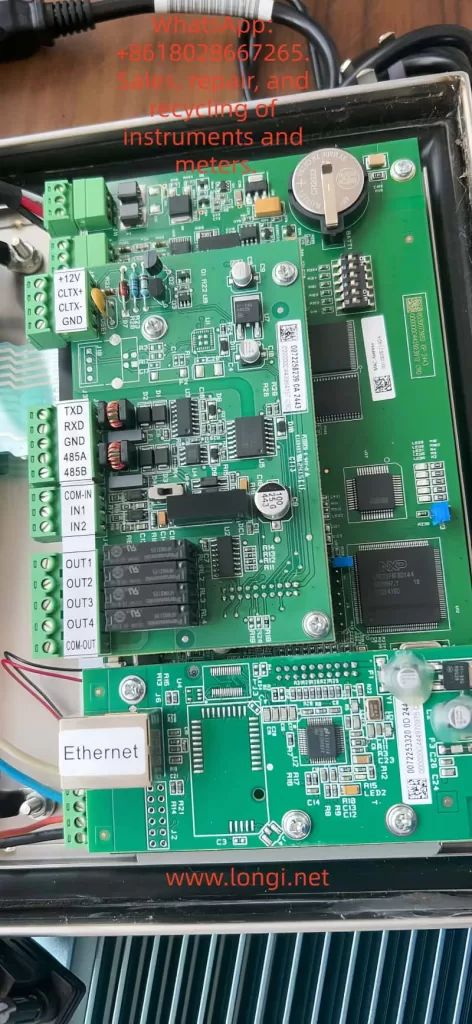

The IND245 Electronic Weighing Instrument operates based on precise signal acquisition, processing, and display technologies. It connects to weighing sensors (either analog or digital types) to convert mechanical force into electrical signals, which are then digitized by an A/D converter and ultimately displayed on an LCD screen as weighing results. The core components include the mainboard, A/D conversion module, microprocessor, and display keyboard.

For analog sensors, the IND245 supports sensors with a 350-ohm load resistance and is compatible with sensitivities of 2mV/V and 3mV/V without additional configuration. The sensor converts weight changes into millivolt-level voltage signals, with the mainboard providing a 10V excitation voltage. The A/D converter performs high-speed digital conversion at a sampling rate of 366Hz. The microprocessor applies digital filtering algorithms (such as low-pass filtering and steady-state detection) to eliminate noise, ensuring accuracy within 6000e (verification divisions).

For digital sensors (such as the SLC720 POWERCELL GDD), the instrument uses the RS-422/485 protocol, supporting up to 12 sensors connected via a 300-meter Homerun cable. Digital signals are transmitted directly, avoiding attenuation and interference inherent in analog transmission, thereby enhancing anti-interference capabilities and precision stability. The instrument incorporates a real-time clock (RTC) and an SD/MicroSD card for data backup and Alibi storage, ensuring tamper-proof transaction records.

The overall principle can be summarized as: Sensor → Signal Excitation/Acquisition → A/D Conversion → Digital Filtering/Processing → Display/Output. The vehicle scale version is specifically optimized for paired weighing functions, supporting inbound/outbound operations, automatically calculating net weight, and ensuring positive output through negative net weight correction, suitable for logistics scenarios.

Key Features

The IND245 stands out for its versatility and cost-effectiveness, with key features including:

- High Precision and Wide Range: Supports up to 50,000 display divisions with an accuracy of 6000e. Automatic zero tracking (AZM) and multi-range switching ensure accurate measurements from微量 (trace amounts) to heavy loads. Adjustable steady-state detection time (0.3-1 second) enables fast dynamic response, suitable for vehicles quickly mounting the scale.

- Flexible Sensor Compatibility: Seamlessly supports 8 analog sensors or 12 digital sensors. The digital version maintains signal integrity over long distances, reducing wiring costs.

- Rich Communication and Integration Options: Standard RS-232/422/485 interfaces support SICS protocol, continuous output, and CTPZ commands. Optional interfaces include USB, Ethernet, and DIO (2 inputs, 4 outputs), facilitating integration with PLCs, PCs, or printers. The vehicle scale version includes built-in preset points and a tare library, supporting 100 temporary and 200 permanent tare records.

- User-Friendly Interface: A 240×96 dot-matrix LCD display supports Chinese and English switching. The 25-key keyboard includes numeric/alphabetic input and navigation keys, with unique digital shortcuts for accelerated menu navigation. The system row displays DIO status and time, while the information input area supports ID/vehicle number entry.

- Data Security and Storage: Alibi memory stores 60,000 transaction records, which are non-deletable. 4000 transaction logs and SD card backup support data recovery. Parameter locking in certification mode prevents tampering.

- Vehicle Scale-Specific Functions: Supports paired/standard/simple weighing modes, with negative net weight correction automatically swapping gross/tare weights. Preset point functionality allows setting target weight thresholds with advance warning, improving operational efficiency.

- Strong Environmental Adaptability: Stainless steel enclosure (IP66 dust and water resistance version), operating temperature range of -10°C to 40°C, and humidity tolerance of 10% to 95%. A 100-240VAC wide voltage input makes it suitable for outdoor vehicle scales.

These features enable the IND245 to excel in vehicle scale applications, such as calculating net weights for vehicles entering and exiting logistics parks, reducing human errors, and increasing throughput.

Technical Specifications

The specifications of the IND245 are detailed in Table 1-1 of the manual. Below is a summary of key parameters presented in a table for easy comparison:

| Parameter Category | Specification Details |

|---|---|

| Form Factor | Standard/Dustproof (IP66), all stainless steel 304L; Tabletop/wall-mounted/pole-mounted installation |

| Dimensions (L×W×D) | 230 mm × 165.3 mm × 146.4 mm |

| Weight | Analog version: 3.2 kg; Digital version: 3.5 kg |

| Power Supply | 100–240 VAC, 50/60 Hz; Analog version: 750 mA; Digital version: 500 mA |

| Display | 240 × 96 LCD dot-matrix screen, refresh rate of 10 times/second, maximum divisions of 50,000 |

| Sensor Support | Analog: 8×350Ω, 2/3 mV/V; Digital: 12×SLC720 (POWERCELL GDD), 300m cable |

| A/D Update Rate | Analog: 366 Hz; Digital: 25 Hz |

| Keyboard | 25 keys (numeric/alphabetic/navigation/function keys) |

| Communication Interfaces | Standard: RS-232/422/485; Options: USB, Ethernet, DIO (2 inputs, 4 outputs) |

| Storage | Alibi: 60,000 records; Transaction logs: 4,000 records; Tare table: 100 temporary/200 permanent |

| Environmental Conditions | Temperature: -10°C to 40°C; Humidity: 10% to 95% (non-condensing) |

| Certifications | China Accuracy Class III, 6000e; OIML/USA/Canada options available |

These specifications ensure the IND245’s reliable operation in industrial environments, supporting diverse needs from static vehicle weighing to dynamic logistics. Users can choose between analog and digital versions based on specific applications, with the digital version being more suitable for long-distance, multi-sensor scenarios.

How to Install and Maintain the Instrument?

Installation Guide

The installation of the IND245 must be carried out by professional personnel to ensure safe grounding and avoid live plugging and unplugging. Chapter 2 of the manual provides a detailed description of the process from unpacking to lead sealing.

1. Unpacking and Preparation

- Opening the Instrument: Use a flat-head screwdriver to loosen the six stainless steel spring clips on the front cover (Figure 2-1). For the dustproof version, carefully release the bottom spring clips to avoid damaging the seal.

- Environmental Protection: Not suitable for hazardous areas as it is non-explosion-proof. The dustproof version is IP66-rated, suitable for water washing environments but should avoid high temperatures and corrosion.

2. Installation Methods

The IND245 supports tabletop, wall-mounted, and pole-mounted installations:

- Tabletop Installation: Attach four rubber pads to the bottom for anti-slip (Figure 2-3).

- Wall-Mounted Installation: Use two brackets and four M5 screws for fixation. Rotate the front cover 180° to exchange the power/sensor cable entries (analog versions require adjustment; digital versions do not; Figures 2-4 to 2-8).

- Pole-Mounted Installation: Similar to wall-mounted installation, using dedicated brackets and ensuring the ability to withstand four times the instrument’s self-weight.

Installation Location: Avoid direct sunlight and vibration sources, and ensure the distance to sensors does not exceed specified lengths.

3. Cabling and Wiring

- Magnetic Ring Installation: Thread each cable through a magnetic ring and loop it near the housing to prevent interference (Figure 2-10).

- Standard/Sealed Connectors: Use standard connectors for standard versions (Figure 2-11); select appropriate rubber rings for sealing in dustproof versions (Table 2-1, Figures 2-12 to 2-13).

- Cable Configuration: Standard versions have eight interfaces (power, DIO, USB, Ethernet, COM1/2, sensors; Table 2-2). Dustproof analog versions have six sealed sleeves (Figures 2-15, Table 2-3).

- Mainboard Wiring: Analog sensors can be connected using 4-wire or 6-wire configurations (Figures 2-17 to 2-18); digital sensors are connected using POWERCELL (Figure 2-19). Connect the AC power supply (L/N/GND; Figures 2-6/2-7).

- Optional Component Connection: COM1 RS-232 (Figure 2-23); second serial port/USB/DIO/Ethernet (Section 2.4.10).

- Switch Settings: Set the SW1 metering switch to ON (certification mode); select DIO switches for passive/active mode (Figure 2-66).

4. Final Steps

- SD/MicroSD Card Installation: Insert into the mainboard slot (Figures 2-67/2-68) for Alibi/backup purposes.

- Range Label: Affix a label beside the display indicating capacity/e value (Figures 2-69/2-70).

- Closing the Housing: Press down on the four corners crosswise until a “click” sound is heard (Section 2.10).

- Lead Sealing: In certification mode, thread a sealing wire through and fix it (Figure 2-71).

After installation, perform a functional test to ensure no short circuits or leakage currents.

Maintenance Guide

Regular maintenance ensures the long-term stability of the instrument. Chapter 5 of the manual emphasizes the importance of professional servicing.

1. Daily Cleaning

- Clean the housing with a neutral detergent and a soft cloth, avoiding industrial solvents. Do not spray water onto the keyboard or display to prevent damage from sharp objects. Regularly inspect and maintain records.

2. Software Upgrades

- Supports online upgrades. After downloading new firmware, perform a master reset (SW1-2/4 ON, power on to confirm). Back up SD card data to avoid memory errors.

3. Routine Inspections

- Professional personnel should perform calibration once a year, checking sensors, cables, and grounding. Verify accuracy and clean internal dust.

4. Service Support

- Contact Mettler Toledo’s service department for support. After on-site installation, only regular calibration is required. Use original factory parts for replacements.

Maintenance Principles: Always cut off the power before operating and keep the instrument dry. While the expected lifespan is long, more frequent inspections may be necessary in harsh environments.

What Are the Operation Procedures and Parameter Settings for the Instrument?

Operation Procedures

The IND245 is designed for ease of use, with Chapter 3 of the manual providing detailed information on the keyboard and main window.

1. Keyboard and Interface

- Keyboard Layout: Includes navigation keys (up/down/left/right/confirm), numeric/alphabetic keys (switchable between 123/ABC/abc), basic function keys (zero/tare/clear/unit), and special keys (sequence number/menu/function/power; Figure 3-2).

- Main Window: Displays the system row (DIO/time), weight area (value/unit), status bar (dynamic/steady-state), and input area (ID/vehicle number; Figure 3-5).

2. Basic Operations

- Power-On: Press the power key to initiate a self-test. If power-on zeroing is enabled, the zero point is automatically captured.

- Weighing: When a vehicle mounts the scale, the gross weight is displayed. Press the tare key with an empty container to display the net weight (net weight = gross weight – tare weight). Switch units if the second unit is enabled.

- Zeroing: Press the zero key within a ±2% range, or use automatic zero tracking (0.5d window).

- Printing: Press the print key to output using predefined templates (A-F). Automatic printing occurs when the weight exceeds 0kg and is stable.

- Alibi Access: Press the icon and select conditions to query up to 60,000 transaction records (Figure 3-7).

- Vehicle Scale Modes: Paired weighing (inbound gross weight + outbound gross weight = 2 tare weights, net weight = gross weight – tare weight); standard weighing (single weighing); simple weighing (basic functions). Preset points allow setting target weights with advance warning.

3. Advanced Operations

- Information Display: Press keys to view system/transaction logs.

- Time and Date: Press keys to set the time and date, with battery backup.

- Reporting: Use the menu to query the tare library/transactions.

Operation Safety: In certification mode, parameters are locked. Press SW1-1 ON to prohibit modifications.

Parameter Settings

Chapter 4 of the manual presents a clear menu tree structure with five main branches: scale platform/application/instrument/communication/maintenance. Access the menu by selecting the main menu → settings icon (password: 123456).

1. Scale Platform Parameters (4.5.1)

- Type: Name “Scale1”, certification “None”, number of sensors 4 (digital version).

- Range/Divisions: Primary unit kg, 1 range 50kg/0.01d (Table 4-1).

- Calibration: GEO=17, linear calibration prohibited. Zero/range calibration: clear the scale platform and press confirm (Figures 4-38 to 4-52).

- Zeroing: Automatic tracking of gross weight/0.5d, underload 20d, power-on prohibited, key ±2%.

- Tare: Key/keyboard allowed, negative net weight prohibited. Automatic threshold 0kg.

- Filtering/Steady-State: Medium low-pass filter, 1d dynamic/0.3s steady-state.

- Logging/Printing: Minimum 0kg, interlock prohibited.

2. Application Parameters (4.5.2)

- Storage: Alibi prohibited.

- DIO: Input positive polarity/none; output none.

- Vehicle Scale: Paired/standard weighing allowed, thresholds 200/50, password 11111111.

3. Instrument Parameters (4.5.3)

- Device: Serial number blank, key interval 800ms.

- Display: Screen saver 10min, backlight 1min, power-off prohibited, system row blank.

- Region: 24:MM:SS/DD MMM YYYY/Chinese.

- Counter: Allowed, modification prohibited.

4. Communication Parameters (4.5.4)

- Templates: 6 templates (A-F), customizable strings (Table 4-3).

- Interface: COM1 command print 9600/8/N.

- Serial Port: Baud rate 9600, data bits 8, parity N.

- Network: DHCP disabled, IP 192.168.0.1.

5. Maintenance Parameters (4.5.5)

- Calibration Tests: Zero/range/linearity.

- POWERCELL Diagnostics: Performance/error logs (digital version).

- Reset: All/scale platform.

Exit settings by pressing the left key to return. In certification mode, press SW1-1 ON to lock scale platform parameters.

What Are the Common Faults of the Instrument, and How to Solve Them?

Common Fault Analysis

The IND245 is designed for reliability, but environmental factors or improper operation may lead to faults. Section 5.4 of the manual lists diagnostic methods.

- Power Issues: No display/restarts.

- Cause: Unstable voltage, loose connections.

- Symptom: LED not lit.

- Display Anomalies: Black screen/distorted display/low contrast.

- Cause: Backlight failure, connection issues.

- Inaccurate Weighing: Drift/zero offset/unstable dynamics.

- Cause: Sensor damage, improper filtering, poor grounding.

- Communication Failures: No print response/data loss.

- Cause: Incorrect baud rate, cable break, protocol mismatch.

- Storage Errors: Unable to access Alibi/SD card read/write failures.

- Cause: Loose card/full capacity, software bugs.

- Keyboard Malfunctions: Unresponsive keys.

- Cause: Dirt/damage.

Fault Resolution Steps

1. Preliminary Checks

- Confirm power supply: Ensure 100-240VAC stability. Use a multimeter to measure L/N/GND (Section 5.4.1).

- Grounding test: Ensure proper grounding with resistance <1Ω.

- Restart: Power off for 5 minutes, then power on again.

2. Power Voltage Check (5.4.2)

- Use a multimeter to measure the mainboard voltages: +5V, +12V, -12V should be stable. Replace the power module if anomalies are detected.

3. RS-232 Test (5.4.3)

- Power off, connect the red probe to the transmit end and the black probe to the ground. Expect -5V to -15V in command mode; ±5V jumping in continuous mode. ±5V during printing. Replace the serial port board if anomalies are detected.

4. Internal Diagnostics

- Navigate to maintenance → calibration tests: zero/range/linearity. Report “command failed–dynamic” during dynamic testing.

- POWERCELL diagnostics (digital version): Log interval 0s, error logs enabled (Section 4.5.5.7).

5. Master Reset (5.4.4)

- Set SW1-2 ON (SW1-4 as needed), power on to confirm. Clears parameters/calibration (EEPROM retained if OFF). Back up SD card data.

6. Advanced Troubleshooting

- Software upgrade: Download firmware and install after master reset.

- Sensors: For analog sensors, check mV output; for digital sensors, measure CAN voltage (Figure 4-131).

- MT Security: Unlock using the Insite tool (Sections 5.5.6.7).

Prevention: Regular calibration, avoid overloading/moisture. Record fault time/symptoms and contact the service department. Common resolution rate >90%, professional repair <5%.

Conclusion

The Toledo ND245 Electronic Weighing Instrument stands as a reliable partner in the vehicle scale field, thanks to its precise principles, rich features, and rigorous specifications. Through proper installation, daily operation, and parameter optimization, users can achieve efficient weighing. Regular maintenance and troubleshooting ensure long-term performance. This guide, approximately 4500 words in length, aims to simplify the application of the manual and recommends combining it with practical testing. For further in-depth information, refer to the original manual or seek professional support. The IND245 empowers your weighing journey, ensuring precision at every step!