Chapter 1 Product Overview and Technical Specifications

1.1 Introduction to the Product System

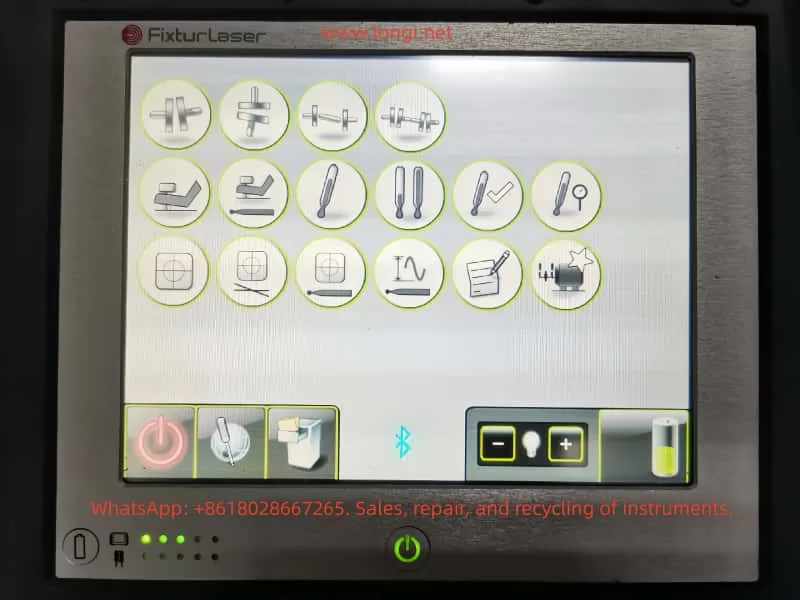

The Fixturlaser NXA series laser alignment instrument is the flagship product of ACOEM AB (formerly ELOS Fixturlaser AB). Since its establishment in 1984, the company has established a complete professional service system in over 70 countries. As an industry-leading solution for shaft alignment, this system is designed based on innovative measurement technology and is widely used in various industrial equipment maintenance fields.

1.2 Core Technical Specifications

Display Unit NXA D Parameters

- Two operating modes: On and Off

- Dust and water resistance rating: IP65

- Processor: 1GHz dual-core main processor

- Memory: 256Mb, Flash storage: 8Gb

- Operating temperature range: -10 to 50℃

- Weight: Approximately 1.2kg (including battery)

Sensor Unit Technical Specifications

- Weight: Approximately 192 grams (including battery)

- Operating temperature: -10 to 50℃

- Protection rating: IP65

Compliance Certifications

- Complies with EMC Directive 2004/108/EC

- Complies with Low Voltage Directive 2006/95/EC

- Complies with RoHS Directive 2011/65/EU

Chapter 2 Analysis of Core System Components

2.1 Functional Characteristics of the Display Unit

- 6.5-inch touchscreen display

- On/off button with status LED

- Battery status check button

- Built-in 256Mb memory and 8Gb flash storage

Sensor Unit Configuration

- M3 and S3 sensors: Anodized aluminum frame design, high-impact ABS plastic casing, TPE rubber overmolding process

2.2 Power Management System

- Built-in high-capacity rechargeable lithium-ion battery pack

- Sustainable usage for approximately 2-3 years under normal operating temperatures

Chapter 3 Safety Operation and Maintenance Procedures

3.1 Laser Safety Operation Standards

- Uses laser diodes with a power output of <1.0mW

- Laser classification: Class 2 safety level

Chapter 4 Core Principles of Laser Alignment Technology

4.1 Theoretical Basis of Alignment Technology

The system utilizes measurement units installed on two shafts. After rotating the shafts to different measurement positions, the system calculates the relative distances between the two shafts in two planes. It is necessary to accurately input the distances between the measurement planes, to the coupling, and to the machine feet.

4.2 System Measurement Advantages

Accuracy Advantages

- 6-axis MEMS inertial motion sensors provide precise data acquisition

- Automatic drift compensation ensures measurement stability

- On-site calibration capability guarantees measurement reliability

Chapter 5 Detailed Practical Operation Procedures

5.1 Preparation Requirements

Pre-Alignment Checklist

- Determine required tolerance specifications

- Check for dynamic movement offsets

- Assess system installation environment limitations

- Confirm shaft rotation feasibility

- Prepare compliant shim materials

5.2 Sensor Installation Specifications

Specific Installation Steps

- The sensor marked “M” is installed on the movable machine, while the sensor marked “S” is installed on the fixed machine.

- Assemble the sensors on their V-block fixtures, precisely placing the fixtures on both sides of the coupling.

- Hold the V-block fixtures upright and correctly install them on the shaft of the measurement object.

- Lift the open end of the chain, tighten the chain to eliminate slack.

- Securely tighten the chain using tension screws, and use dedicated tension tools if necessary.

Installation Accuracy Control Points

- Adjust the sensor height by sliding it on the column until a clear laser line is obtained.

- Lock the final position using the clamping devices on the backs of both units.

Chapter 6 Measurement Methods and Technology Selection

6.1 Rapid Mode Method

Technical Characteristics

- Calculates alignment status by recording three points

- Requires a minimum rotation angle of 60°

- The system automatically records each measurement point

6.2 Three-Point Measurement Method

- Performs alignment calculations by manually acquiring three points

- All measurement points must be manually collected

6.3 Clock Method Technique

- Acquires three measurement points through 180° rotation

- Computes accurate mechanical position information

- Suitable for comparison and analysis with traditional methods

Chapter 7 Data Processing and Quality Management

7.1 Measurement Result Evaluation

- Angle and offset values jointly determine alignment quality

- Compare actual values with preset tolerance standards for analysis

- Evaluation results directly determine whether further corrections are needed

Chapter 8 Analysis of Professional Application Technologies

8.1 Softcheck Soft Foot Detection

- Uses the built-in Softcheck program system for detection

- Provides precise measurements and displays results for each foot (in millimeters or mils)

8.2 OL2R Application Technology

Measurement Condition Requirements

- Must be performed under both operating and cold conditions

- The system automatically calculates and evaluates process variables

8.3 Target Value Presetting Technology

Preset Condition Analysis

- Most equipment generates heat changes during operation

- Ideally, the driven and driving equipment are affected to the same extent

- Enables target value presetting under cold conditions

Chapter 9 Professional Maintenance Requirements

9.1 Cleaning Operation Procedures

- The system surface should be wiped with a damp cotton cloth or swab

- Laser diode apertures and detector surfaces must be kept clean

- Do not use any type of paper towel material

- Strictly prohibit the use of acetone-based organic solvents

9.2 Power Management Maintenance

Battery Service Life

- Under normal usage conditions, the battery life is typically valid for approximately 2-3 years

9.3 Battery Charging Specifications

- Full charging time is approximately 8 hours

- When not in use for an extended period, charge to 50-75% capacity

- It is recommended to perform maintenance charging every 3-4 months

Chapter 10 Fault Diagnosis and Repair Procedures

10.1 System Anomaly Detection

- Check battery level

- Confirm good charging status

- Ensure Bluetooth device connection is normal

Chapter 11 Quality Assurance System

11.1 Repeatability Testing

- Must be performed before each measurement

- Establish correct sampling time parameter settings

- Effectively avoid the influence of external environmental factors

Chapter 12 Technological Development Trends

12.1 Intelligent Development Directions

- Integration of Internet of Things (IoT) technology

- Remote monitoring and diagnostic capabilities

- Application of digital twin technology

12.2 Precision Development Directions

- Continuous improvement in measurement accuracy

- Optimization and improvement of operational procedures

- Expansion and enhancement of system functions

Through an in-depth technical analysis of the Fixturlaser NXA series products, operators can fully grasp the core technological points of the equipment, thereby fully leveraging its significant value in the field of industrial equipment maintenance. This enables a notable increase in equipment operational efficiency and reasonable control over maintenance costs.