Introduction

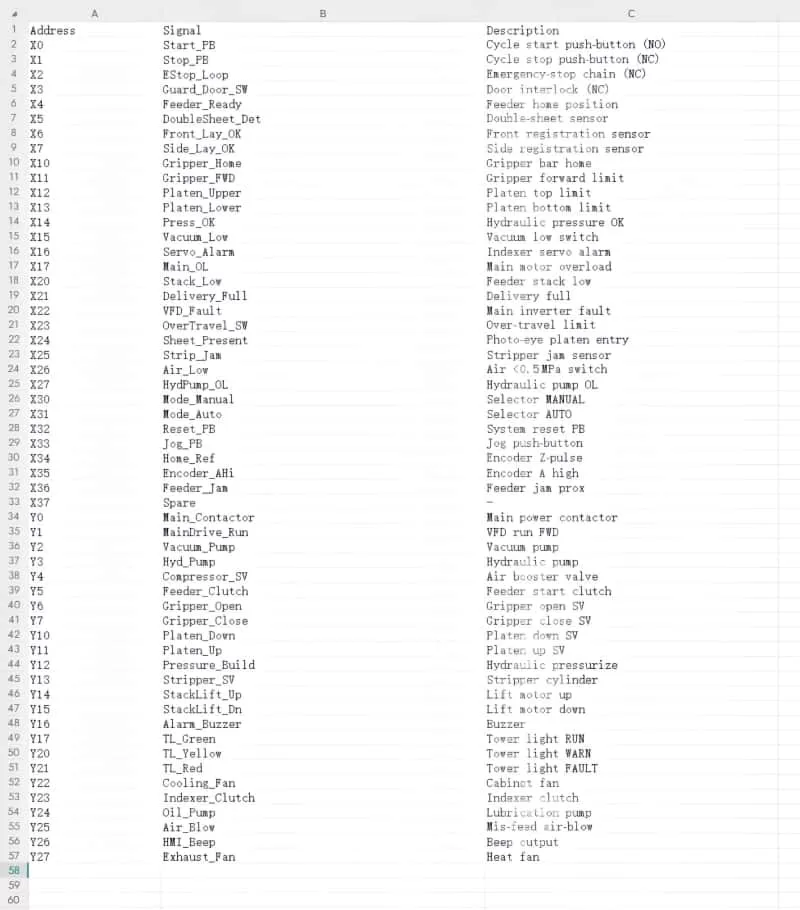

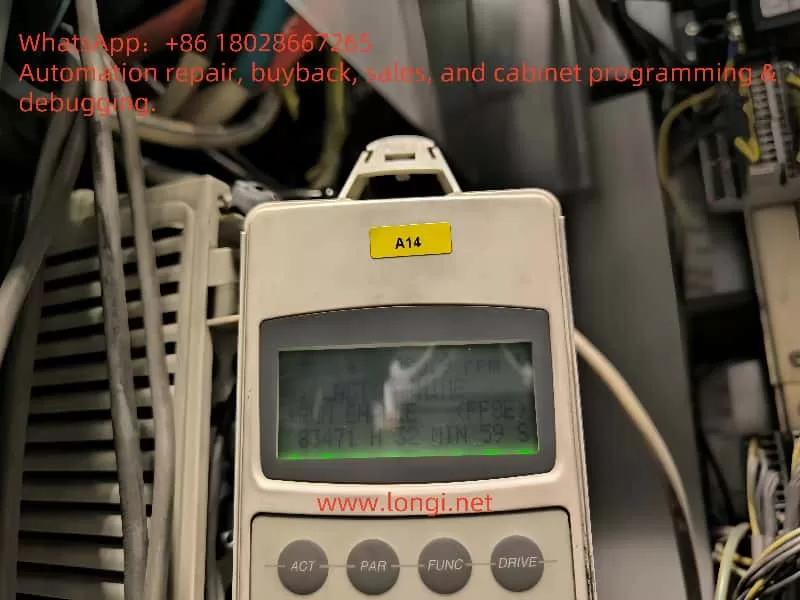

The ABB ACS800 series frequency converter is a robust solution widely used in industrial applications, supporting a power range from 0.75 to 7500 horsepower. However, one common issue users may encounter is the FF8E warning, which signals that the drive has not received the “Run Enable” signal required for operation. This article provides a detailed exploration of the FF8E warning, its causes, diagnostic steps, and solutions, drawing from official documentation and practical insights to guide users effectively.

Understanding the FF8E Warning

The FF8E warning, classified as a “Run Enable” alert in the ACS800 series, indicates that the drive has not detected the necessary signal to start or continue motor operation. This signal serves as a safety and control mechanism, typically provided by an external device such as a PLC, control panel, or through fieldbus communication. When this signal is missing, the drive cannot operate, potentially disrupting production. The root causes of the FF8E warning generally fall into categories like parameter misconfiguration, wiring issues, or, less commonly, hardware faults.

Causes of the FF8E Warning

Based on ABB documentation and online discussions, the FF8E warning can be attributed to several potential causes:

- Parameter Configuration Issues

- Incorrect Parameter 16.01 (RUN ENABLE) Setting: This parameter defines the source of the run enable signal. If misconfigured, the drive will fail to detect the signal.

- Setting Options:

- YES: Internal enable, no external signal required.

- DI1-DI12: Signal provided via a specified digital input, which must be active.

- COMM.CW: Signal provided via fieldbus communication, requiring active communication.

- Setting Options:

- Signal Not Active: Even with the correct setting, if the digital input is not energized or the communication control word is not sent, the warning will persist.

- Communication Failure: When set to COMM.CW, any interruption in fieldbus communication or failure to send the correct control word can trigger the FF8E warning.

- Incorrect Parameter 16.01 (RUN ENABLE) Setting: This parameter defines the source of the run enable signal. If misconfigured, the drive will fail to detect the signal.

- Wiring Issues

- Poor 24VDC Contact: Unstable 24VDC power supply at pins 8 and 11 of the socket (e.g., due to loose contacts or corrosion) can disrupt the digital input signal.

- Faulty Signal Source Wiring: Loose or damaged wiring for the run enable signal source can prevent the signal from reaching the drive.

- Hardware Issues

- Mainboard or Digital Port Circuit Failure: Though rare, a damaged mainboard or digital port circuit can prevent the drive from detecting the signal. This is typically considered only after ruling out other causes.

- Optional I/O Module Misconfiguration: If using extended I/O modules, improper configuration can lead to signal transmission failures.

Diagnostic and Resolution Steps

To effectively address the FF8E warning, users should follow these systematic steps:

- Verify Parameter 16.01 Settings

- Using the drive’s control panel or a parameter configuration tool, confirm that parameter 16.01 aligns with the intended control method. For instance, if using a digital input, set it to the corresponding DI number; if using fieldbus, set it to COMM.CW.

- Refer to the ACS800 Standard Control Program Firmware Manual (pages 42 and 252) for detailed parameter descriptions.

- Validate the Run Enable Signal

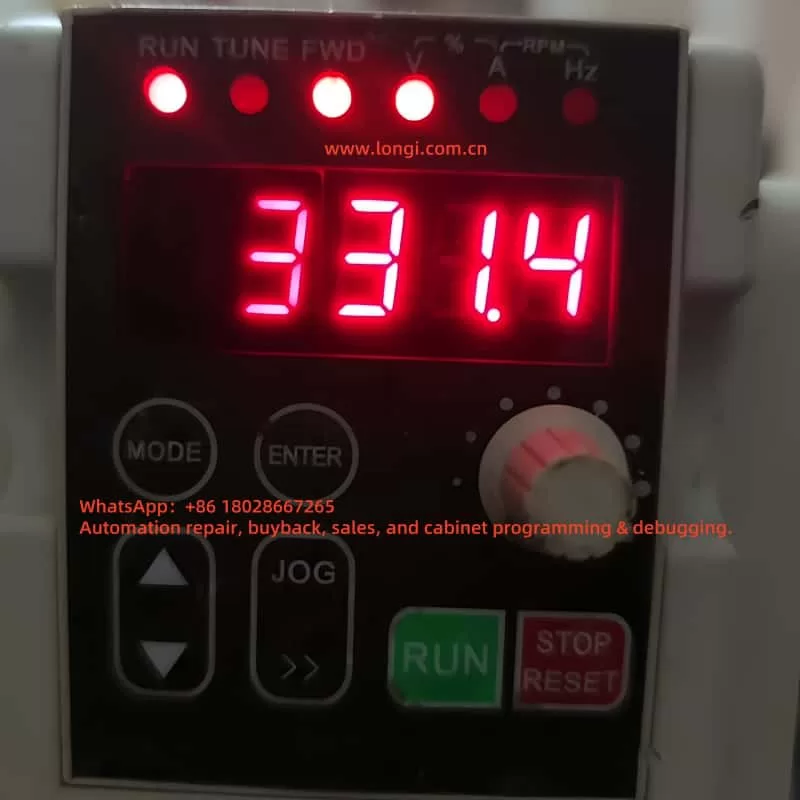

- Digital Input: Check if the specified digital input (e.g., DI1-DI12) is active. This can be verified via the control panel or by measuring the voltage at the input terminal with a multimeter.

- Communication Control: If using COMM.CW, ensure the fieldbus (e.g., Modbus or Profibus) connection is active and the control word (Main Control Word 03.01, bit 3) is correctly sent.

- Inspect Wiring

- Focus on the 24VDC supply at pins 8 and 11 of the socket, ensuring secure contact with no looseness, corrosion, or contamination.

- Check the wiring of the run enable signal source for continuity, ensuring there are no open circuits or shorts.

- Check Optional I/O Modules

- If the drive uses extended I/O modules, verify the settings in parameter group 98 (OPTION MODULES) to ensure the module is correctly configured and active.

- Hardware Inspection

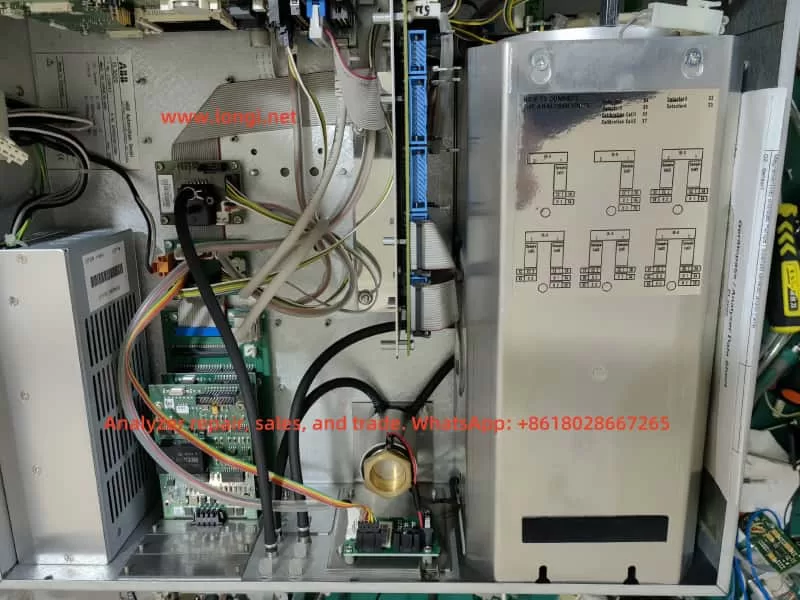

- If the above steps fail, a hardware issue may be present. Open the drive and inspect the mainboard and digital port circuits for visible damage or poor connections.

- Replacing the mainboard should be a last resort, pursued only after confirming a hardware fault, and ideally under guidance from ABB technical support.

- Consult Official Documentation and Support

- Refer to the ACS800 Firmware Manual sections on “Start/Stop Control” and “Fault Tracing” for additional guidance.

- For complex issues, contact ABB technical support for professional assistance.

Deep Dive into Parameter 16.01

Parameter 16.01 (RUN ENABLE) is central to resolving the FF8E warning. Below is a detailed breakdown:

| Parameter Name | Default Setting | Function Description | Setting Options |

|---|---|---|---|

| 16.01 RUN ENABLE | YES | Selects the source of the run enable signal, determining if the drive is allowed to operate | – YES: Internal enable, no external signal needed – DI1-DI12: Controlled via digital input – COMM.CW: Controlled via fieldbus |

- Key Notes:

- When using the Generic Drive protocol, set parameter 16.01 to “YES” to enable control via the fieldbus (Main Control Word 03.01, bit 3).

- The run enable signal must be active for the drive to respond to start commands, such as an ID Run.

Hardware Concerns: Mainboard and Digital Port Circuits

While the FF8E warning is typically caused by configuration or wiring issues, hardware faults—such as a damaged mainboard or digital port circuit—can also prevent signal detection. These issues are less common and should only be considered after exhausting other troubleshooting steps. Replacing the mainboard is a costly and complex solution, requiring professional guidance to avoid further damage or warranty issues.

Preventive Maintenance

To minimize the occurrence of FF8E warnings, consider the following preventive measures:

- Regular Wiring Checks: Ensure all control signal wiring is secure, with no looseness or corrosion.

- Environmental Monitoring: Maintain a clean, dry, and well-ventilated environment for the drive, avoiding dust buildup or overheating.

- Firmware Updates: Regularly check for and install firmware updates from ABB to address potential bugs.

- Parameter Documentation: Keep a record of parameter settings and changes for easier troubleshooting in the future.

Conclusion

The FF8E warning on the ABB ACS800 frequency converter indicates a missing run enable signal, often due to misconfigured parameter 16.01, poor 24VDC contact, or wiring issues. By systematically checking parameters, signals, wiring, and communication, most issues can be resolved. Hardware faults, such as mainboard or digital port circuit failures, are rare and should only be addressed after other possibilities are ruled out. Routine maintenance and proper configuration are key to ensuring the reliable operation of the ACS800 drive.