The rolling of tea leaves is a critical process in tea production. Its main goal is to twist the leaves into tight strips, rupture some of the leaf cells to promote the release of tea juice, and enhance the aroma and liquor of the tea. The tea rolling machine, as the key mechanical equipment for this task, has gradually replaced traditional manual rolling and is now widely used in the production of black, green, oolong, and other types of tea.

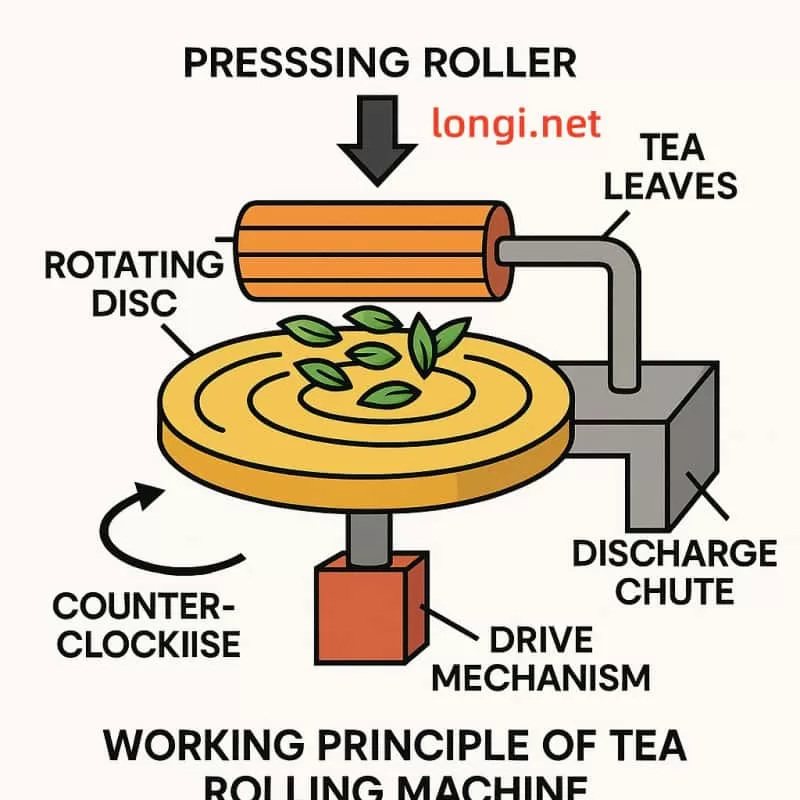

1. Working Principle of the Tea Rolling Machine

The rolling machine operates by applying pressure between a top press cover and a rotating bottom disc, sandwiching the tea leaves. Through the combined motion of pressing and rotation, the leaves are subjected to extrusion, friction, and kneading forces, causing them to bend, twist, and partially rupture. This helps to form the desired strip shape and allows the internal tea juice to be released.

The main forces at work during rolling include:

- Shear Force: Facilitates shaping by shearing the leaves between two surfaces;

- Frictional Force: Generated as the leaves tumble between the disc and the cover, enhancing curl formation;

- Vertical Pressure: Continuously applied by the top cover to control the rolling intensity and leaf breakage rate.

The rolling process typically follows a sequence of “light pressure – medium pressure – heavy pressure – decompression” to ensure optimal shaping and internal quality.

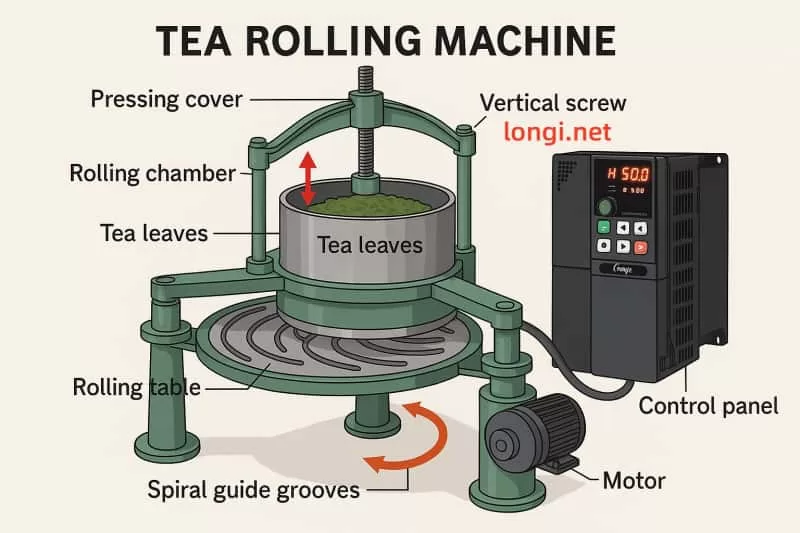

2. Key Structural Components

Tea rolling machines are robustly built and functionally arranged, typically consisting of the following parts:

- Main Frame and Base Support

Made of cast iron or steel, often tripod-style for excellent stability and vibration resistance. - Rolling Disc (Rotating Plate)

Located at the base, made from stainless steel or cast aluminum, featuring spiral guide ribs to move the tea in a circular path. The surface is polished for easy cleaning. - Rolling Drum (Barrel)

A cylindrical chamber fixed above the rotating disc where tea leaves are placed. Smooth and seamless inside for even rolling. - Pressing Cover Mechanism

Positioned above the barrel, adjustable manually or electrically. The inner surface is curved or grooved to apply even downward pressure. A spring mechanism provides buffering. - Motor and Gearbox Drive

Drives the rotating disc via belts or gears. Speed is typically reduced to 30–60 rpm for controlled operation. - Control Panel

May include timers, press height adjustment knobs, power switches, and emergency stops. - Discharge Port

Once rolling is complete, tea is discharged by lifting the cover or opening a side outlet. Some models have scraper mechanisms for efficient leaf removal.

3. Operational Workflow

1. Leaf Loading

Processed (withered or de-enzymed) leaves are evenly spread into the barrel. No pressure is applied at this stage.

2. Initial Pressing

The press cover is gently lowered to just contact the leaves, stabilizing their position and forming the initial shape.

3. Rolling Phase

The motor activates the rotating disc. Under spiral guidance, the leaves tumble while being pressed by the top cover. This produces combined shearing and extrusion forces. Duration is 3–10 minutes depending on the tea type and batch size.

Rolling can be broken down into:

- Light rolling (low pressure, low speed)

- Medium rolling (increased pressure, steady speed)

- Heavy rolling (max pressure, fixed speed)

- Final shaping (reduced pressure, slow speed)

4. Discharging

The motor stops, the press cover is lifted or the outlet opened, and the rolled leaves are released.

5. Cleaning and Reset

Residual tea is cleaned off the disc and barrel to prepare for the next batch.

4. Technical Specifications

| Item | Typical Range | Description |

|---|---|---|

| Motor Power | 1.1–3 kW | Depends on size and capacity |

| Rolling Disc Diameter | 500–1200 mm | Larger size accommodates higher loads |

| Rotation Speed | 30–60 rpm | Adjustable per tea type |

| Pressing Stroke | 100–180 mm | Defines maximum compression depth |

| Rolling Time | 2–15 minutes | Varies by tea type |

| Batch Capacity | 10–100 kg per batch | Based on machine model |

| Pressing Mechanism | Manual / Electric / Pneumatic | Varies in precision and efficiency |

5. Control Logic Overview

Modern machines include integrated control features such as:

- Time Setting: Allows rolling duration to be preset;

- Press Cover Control: Motorized or electric actuator to fine-tune press height and pressure;

- Speed Regulation: When equipped with an inverter, stepless speed control is achievable;

- Emergency Stop: Ensures safe halt during abnormal operation;

- Directional Control: Enables clockwise and counterclockwise rotation alternation for uniform rolling.

These systems promote repeatable, standardized rolling results and reduce operator dependency.

6. Structural Advantages and Craft Adaptability

- Durable, Low-Wear Construction: Cast frame design minimizes vibration and extends service life;

- Adjustable Pressure Cover: Adapts to different moisture levels and leaf volumes;

- Spiral Ribbed Disc: Ensures continuous tumbling and even pressure distribution;

- Easy Maintenance: Smooth surfaces reduce cleaning time and prevent residue build-up;

- Automation-Friendly: Compatible with external control systems or PLC upgrades.

7. Process Optimization Through Variable Speed Control

In modern tea production, varying tea varieties demand different rolling speeds and pressures. Equipping the machine with a variable frequency drive (VFD) allows flexible speed regulation to match these needs.

By adjusting the disc speed based on tea type (e.g., low speed for green tea, medium for black tea), the shaping and juice extraction can be precisely controlled. Multi-stage speed profiles—such as low for initial shaping, medium for heavy rolling, and low again for final adjustment—are easily managed by inverter systems, ensuring quality and efficiency.

A high-performance inverter like the Longi 900 series offers precise speed control, strong torque at low speeds, smooth acceleration, and good compatibility with industrial tea machinery. This enhances the consistency of rolling results while optimizing energy use and equipment protection.

8. Conclusion

The tea rolling machine is central to the quality of processed tea. Its structural design, technical parameters, and control mechanisms must harmonize with tea characteristics to ensure optimal results.

As electrical and automation technology evolves, upgrading rolling machines with intelligent control and variable speed capability is becoming a standard in tea factory modernization. These advances preserve traditional craftsmanship while enhancing efficiency, consistency, and adaptability in production.