Introduction

In modern industrial automation, variable frequency drives (VFDs) are pivotal for motor control, widely utilized across industries such as manufacturing, energy, and transportation. The INDVS Y300 series VFD stands out for its exceptional performance and reliability, making it a preferred choice for many businesses. However, users may occasionally encounter the ERR14 error, which indicates module overheating. This error can interrupt production and potentially damage equipment if not addressed promptly. This article offers an in-depth exploration of the ERR14 error, covering its technical basis, causes, solutions, and preventive strategies to help users maintain stable and efficient operations.

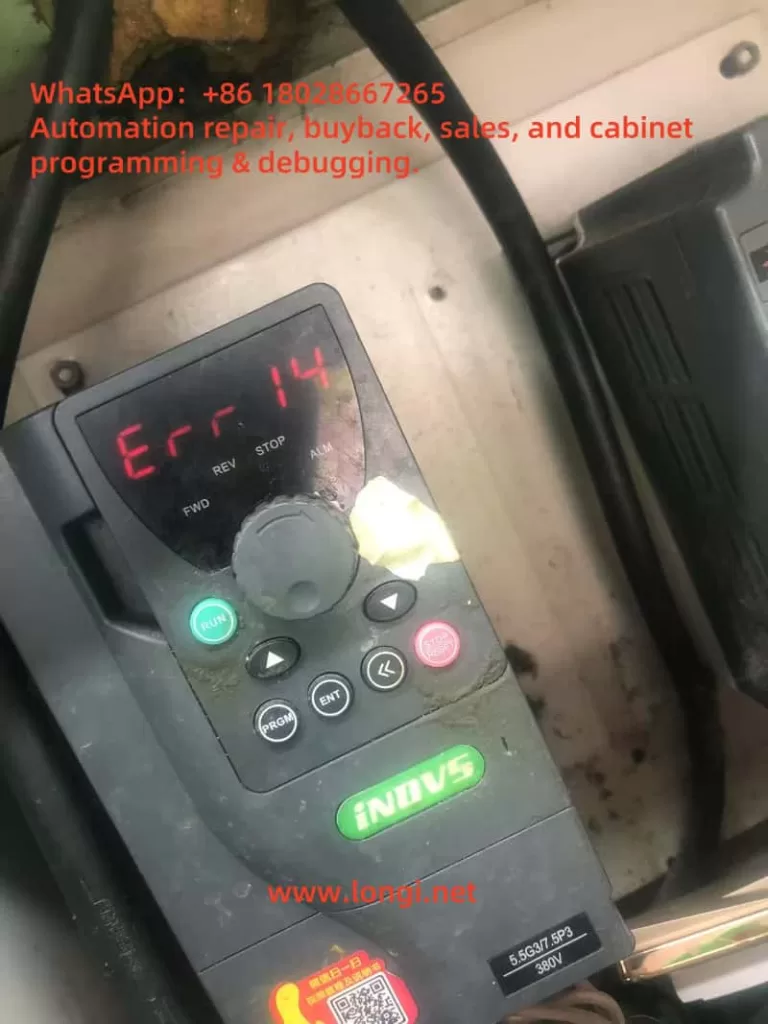

Definition and Impact of ERR14 Error

According to the INDVS Y300 series VFD user manual, the ERR14 error is a safety feature triggered when the power module’s temperature exceeds a predetermined safe limit. The power module, a vital component, converts input power into the specific frequency and voltage needed to drive the motor. Overheating prompts the VFD to shut down automatically, protecting the system from further harm. While this protective mechanism is effective, repeated incidents can lower production efficiency and, in extreme cases, destabilize entire production lines. Addressing the ERR14 error is thus critical for operational continuity.

The consequences of overheating are far-reaching. Sustained high temperatures can accelerate the degradation of the power module, reducing its lifespan. Moreover, the downtime caused by such errors can lead to significant economic losses, especially in continuous-operation settings. Identifying and resolving the underlying issues quickly is therefore a key priority for users.

Potential Causes of ERR14 Error

Understanding the root causes of the ERR14 error is the first step toward effective resolution. Based on the user manual and practical insights, the following factors are commonly responsible:

1. Excessive Ambient Temperature

The VFD operates optimally within a temperature range of -10°C to 40°C, as specified in the manual. When ambient temperatures exceed this limit—such as during hot seasons or in confined spaces—heat dissipation becomes less efficient, resulting in module overheating.

2. Poor Ventilation

The VFD depends on internal fans and heat sinks to manage heat. Dust and debris buildup can block airflow, impairing the cooling system’s performance. The manual emphasizes regular cleaning to ensure effective ventilation.

3. Overloading

Prolonged operation under heavy loads causes the power module to generate excessive heat. Incorrect parameter settings, such as insufficient current limits, can worsen this problem. The manual links load levels to heat output, urging users to configure settings carefully.

4. Improper Installation

The VFD’s installation site and surrounding space affect heat dissipation. The manual advises maintaining adequate clearance around the unit and avoiding proximity to heat sources or stacked equipment. Non-compliance with these guidelines can lead to heat buildup.

Diagnosis and Solutions for ERR14 Error

When the ERR14 error occurs, immediate action is necessary. Below is a step-by-step guide to diagnose and resolve the issue:

1. Safe Power-Down and Cooling

Upon receiving the overheating alert, disconnect the power supply and let the VFD cool down to a safe temperature. The manual suggests using a soft brush or compressed air to clean the cooling system, cautioning against liquids to avoid damaging components.

2. Inspect the Cooling System

Open the VFD casing to check the fans for proper operation and the heat sinks for dust accumulation. Replace faulty fans and ensure clear airflow paths.

3. Parameter Adjustment

Access the control panel to confirm that current limits and thermal protection settings are appropriate. The manual provides guidance on adjusting these parameters, recommending that users save the original settings beforehand.

4. Motor and Wiring Inspection

Use an insulation tester to detect short circuits or insulation issues in the motor and wiring. Such faults can cause abnormal currents, indirectly contributing to overheating.

Preventive Measures and Long-Term Solutions

Fixing the ERR14 error is only part of the solution; preventing its recurrence is equally vital. Here are some proactive steps:

1. Regular Maintenance

Set up a routine maintenance plan, including monthly cleaning of the cooling system and quarterly reviews of fans and settings. The manual’s suggested intervals can guide this schedule.

2. Environmental Optimization

Install the VFD in a well-ventilated, temperature-regulated area. In hot environments, consider adding external cooling solutions like fans or air conditioning.

3. Operator Training

Provide thorough training on the manual’s operational guidelines, ensuring staff can adjust parameters and perform inspections competently, thus improving equipment oversight.

4. Smart Monitoring

Utilize the Modbus communication protocol outlined in the manual to implement a temperature monitoring system. This allows real-time observation of module conditions and early warnings of potential issues.

Technical Principles and Application Scenario Analysis

To fully grasp the ERR14 error, it helps to examine its technical origins. The power modules in VFDs typically employ Insulated Gate Bipolar Transistors (IGBTs), which produce heat during operation. This heat is proportional to the square of the current and the switching frequency. High loads or overly permissive parameter settings increase heat buildup. If the cooling system cannot dissipate this heat effectively, the temperature exceeds the safety threshold, activating the ERR14 error.

In real-world scenarios—like pump control in petrochemical plants or spindle drives in textile production—VFDs often face sustained high loads. These applications demand robust cooling designs and precise parameter tuning. During selection and setup, users must evaluate operational needs carefully to prevent problems arising from poor planning.

Conclusion

The ERR14 error in the INDVS Y300 series VFD, though a frequent challenge, can be managed systematically. By understanding its causes, applying targeted fixes, and adopting preventive measures, users can minimize overheating risks, ensuring the equipment’s long-term reliability and performance. This article has offered a detailed roadmap—from technical details to actionable steps—to empower users in mastering industrial automation challenges with confidence.