Introduction

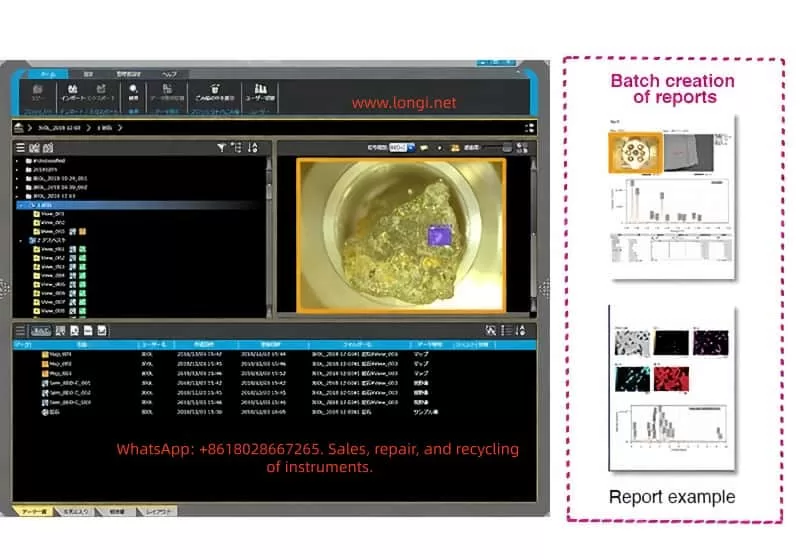

SMILE VIEW Lab is a professional data management and analysis software specially designed by JEOL Ltd. for electron microscope systems. It supports the processing and analysis of data collected from JEOL high-end instruments such as JXA-ISP100, JXA-iHP200F, JSM-F100, and JSM-IT800. It integrates Sample Navigation System (SNS) images, Scanning Electron Microscope (SEM) images, Energy Dispersive X-ray Spectroscopy (EDS) data, and positional information, storing them in project files. This guide aims to provide comprehensive and original technical guidance to help users fully master the software from installation to advanced applications.

Software Overview and Installation

Core Functions

- Data Integration: Links sample images, electron microscope images, and EDS results, supporting graphical representation of positions.

- Analysis Tools: Offers functions such as spectrum editing, one-dimensional comparative spectra, line profiles, and pop-up spectra editing.

- Advanced Visualization: Supports 3D surface topology reconstruction, viewing at any zoom level and angle, and surface roughness standards conforming to ISO/JIS/ASME.

- Report Generation: Features an intuitive layout editor, supports PDF/Word export, and multi-page document creation.

- Compatibility: Seamlessly integrates with specific JEOL models and supports miXcroscopy™ image positioning.

Pre-installation Preparations

- System Requirements: Windows operating system (Windows 10 or higher recommended), at least 8GB RAM, Intel i5 or equivalent processor, dedicated graphics card (supporting OpenGL), and sufficient storage space.

- Software License: Non-exclusive and non-transferable; reverse engineering or copying is prohibited.

Installation Steps

- Download the installation package (.exe file) from the JEOL official website or authorized channels.

- Double-click the installer and select the installation path (default: C:\Program Files\JEOL\SMILE VIEW Lab).

- Accept the license agreement and install dependent components such as .NET Framework.

- After installation, restart the computer and activate the software with administrator privileges.

- If integrating EDS, configure standard data and measurement conditions.

Starting the Software

Starting Methods

- Click the “Data” button through SEM Center.

- Select “Project – Data management” from the File menu.

Starting Process

- Ensure that the JEOL instrument is connected and data has been collected.

- Open SEM Center and navigate to the data management option.

- Click to start, and the software loads the database, displaying the project tab panel.

- During the first start, the software may prompt you to configure user accounts (administrator privileges are required for data sharing).

Precautions

- Avoid operating in environments with high electromagnetic interference and ensure the computer is grounded.

- Software version information can be viewed under the Help tab.

Screen Configuration

Interface Layout

- Project Tab Panel: The core data management area, including the Ribbon menu, address bar, project file list, collected data list, and sample image area.

- Favorite Tab Panel: A collection of shortcuts for quick access to frequently used projects or data.

- Report Tab Panel: The report management area, supporting preview, deletion, and export of report files.

- Layout Tab Panel: The layout editor for customizing report templates.

Ribbon Menu

- Home: Copy projects, import/export data, search, toggle display, and access the recycle bin.

- Setting: Chemical formula calculation, standard data management, EDS settings, report settings, and measurement conditions.

- Admin (Administrator Only): Data sharing and database maintenance.

- Help: Version information.

Mouse and Touch Operations

Supports click selection, right-click menu, drag-and-drop adjustment, and pinch-to-zoom. The interface supports customization, such as changing display formats or sorting data.

Data Management

Operations from the Ribbon

- Copy Project: Select a project and click Copy Project.

- Import Data: Supports importing project/sample unit jlz files.

- Export Data: Export in jlz format, supporting sample units, reports, and layouts.

- Search Data: Search for files in the project list.

- Display Toggle: Classify and display data types.

- Recycle Bin Operations: Temporarily store deleted files and support recovery.

- Data Sharing: Administrators set up sharing among users.

- Version Check: Display the software version.

Project File List Operations

Create new projects, move samples, filter and display formats, and right-click menu operations (rename, send to recycle bin, copy, export, batch analyze spectra, move to other projects).

Sample File Operations

Right-click menu operations (rename, delete, export, batch analysis, move).

Collected Data Operations

Double-click to open the analysis window, and right-click menu operations (open, delete, add to favorites, restore conditions/stage positions, add to report, save as other formats, correspondence program, particle size analysis).

Other Functions

Restore conditions, restore stage positions, add to report, save formats, correspondence program, particle size analysis.

Checking and Editing Collected Data

Opening Collected Data

Select data and double-click to display the analysis window.

Editing Sample Images

Adjust brightness, contrast, rotation, and mark positions.

Editing Electron Microscope Images

Zoom, measure distances/angles, and enhance images.

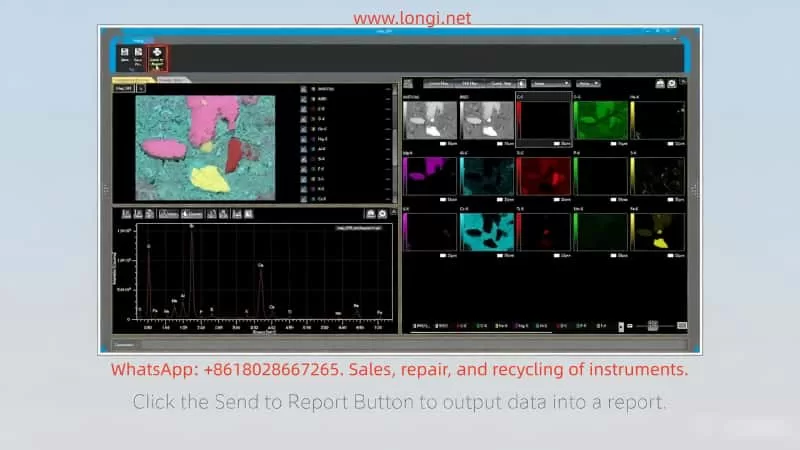

Spectrum Analysis

Edit one-dimensional comparative spectra, adjust baselines, identify peaks, and quantify.

Line Analysis

Edit profiles, smooth curves, and extract data.

Mapping Analysis

Edit pop-up spectra and adjust line profiles.

Correspondence Program (Image Alignment)

Starting Method

Select Correspondence from the data right-click menu.

Operation Steps

- Specify Matching Mode: Automatic positioning or manual.

- Automatic Positioning: Specify the input image, magnification (Mag), region of interest (ROI), set parameters, and run processing.

- Manual Positioning: Manually adjust image overlay.

- miXcroscopy™ Image Positioning: Specific integration mode.

- Fine-tune Partial Images: Move, resize, and rotate.

- Adjust Image Quality: Brightness and contrast.

- Save Results: Export aligned images.

- Scale Space Detection: Use image pyramids to optimize matching.

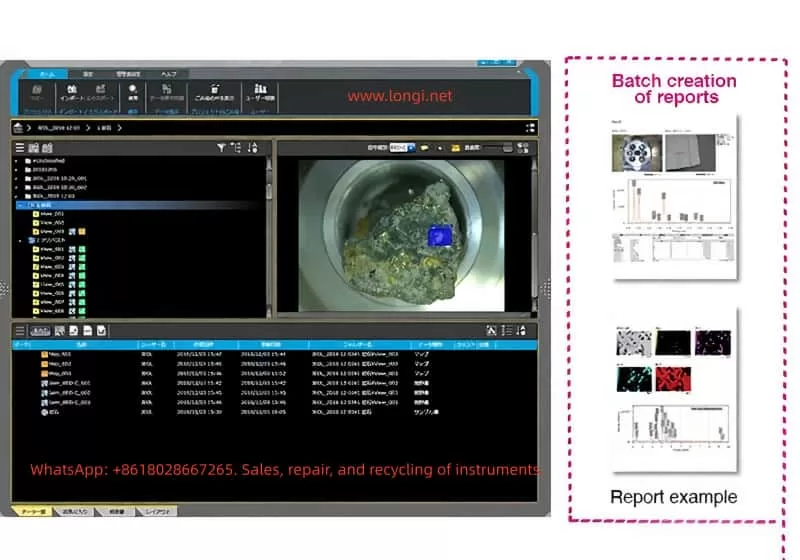

Report Generation

Screen Configuration

The report creation window includes a layout editor, data list, and preview.

Creating a Report

Select a template and create a new layout base.

Editing a Report

Add data, covers, and headers/footers.

Creating a New Layout

Use the layout editor to add items, adjust positions, and save.

Adding Data

Add from the list or analysis screen, supporting comparison.

Adding Covers/Headers/Footers

Customize text and page numbers.

Exporting Reports

Export as electronic data (PDF/Word) or print.

Transferring Data to Other Computers

Exporting Data

Select projects/samples/reports/layouts and generate jlz files.

Importing Data

Select jlz files and import them into new projects, supporting Windows Explorer drag-and-drop.

Precautions

Ensure compatibility and back up data before transfer.

Database Maintenance Tools

Starting/Closing

Start from the Admin tab and confirm closing.

Backup

Select the source/target and perform backup.

Restore

Restore data from backup.

Path Change

Move the data folder and use backup data.

Error Messages

Handle common issues such as invalid paths.

Troubleshooting

Common Problems

- Startup Failure: Check the license and system requirements.

- Data Import Errors: Verify the jlz format.

- Analysis Window Unresponsiveness: Restart the software and check memory.

- Report Export Failure: Confirm permissions and update the software.

Contact Information

If problems persist, contact the JEOL service office.

Software Warranty

The warranty period is 12 months, covering hardware/software failures but excluding improper operation.

Conclusion

SMILE VIEW Lab, as a key component of the JEOL ecosystem, significantly enhances the efficiency and accuracy of electron microscopy analysis. Through this guide, users can master comprehensive skills from basic operations to advanced functions. It is recommended to practice with actual data and regularly update the software to access new features. In the future, with AI integration, this software will further optimize automated analysis and drive scientific research innovation.