Schneider Electric Altivar ATV71, a classic high-performance inverter, is widely used in the field of industrial automation. However, in practical use, the SSF (Torque or Current Limitation Fault) has become one of the more common faults, especially being easily misread as “S5F” or “55F” on the seven-segment LED display. This article will provide an in-depth analysis of the generation mechanism, triggering conditions, common causes, diagnostic methods, troubleshooting steps, and preventive measures for the SSF fault.

I. Overview of SSF Fault

The SSF fault indicates that the inverter has been in a torque or current limiting state for an extended period, and after exceeding the set timeout time, it triggers a protective shutdown. This is a “soft” protective fault. Unlike instantaneous hard protections such as SCF (Motor Short Circuit) or OCF (Overcurrent), it is based on time judgment and aims to protect the motor and mechanical system from damage caused by long-term high-load operation.

II. Characteristics and Misreading of SSF Fault Code

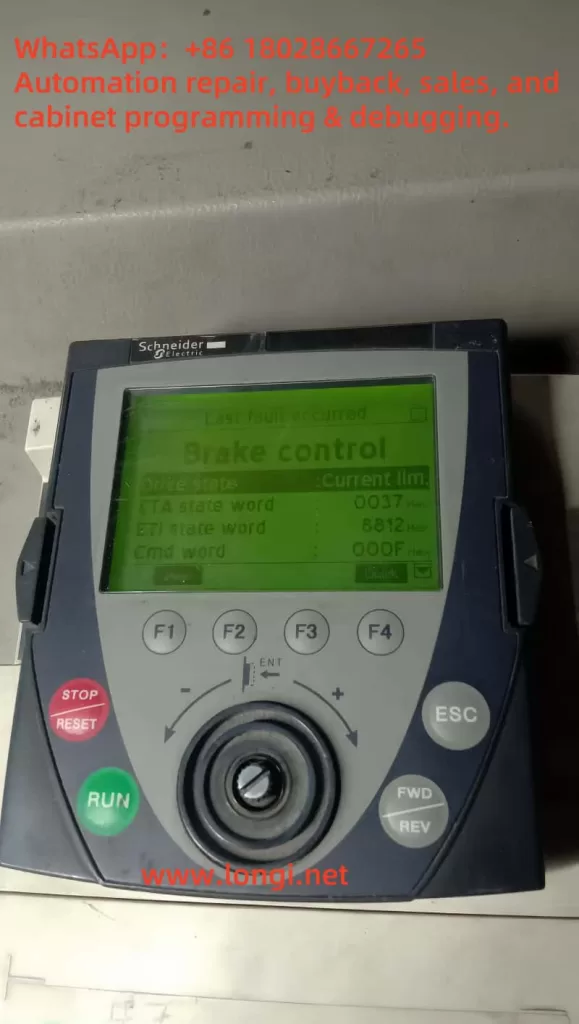

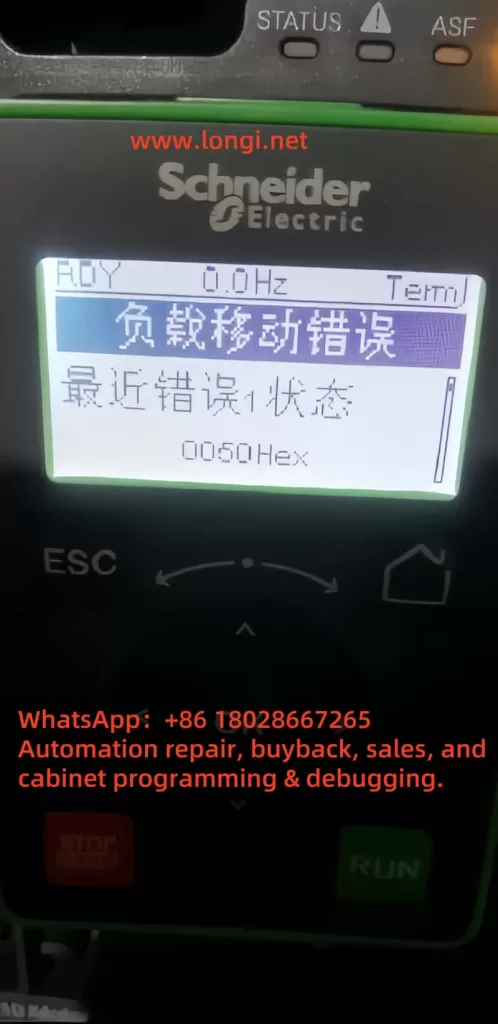

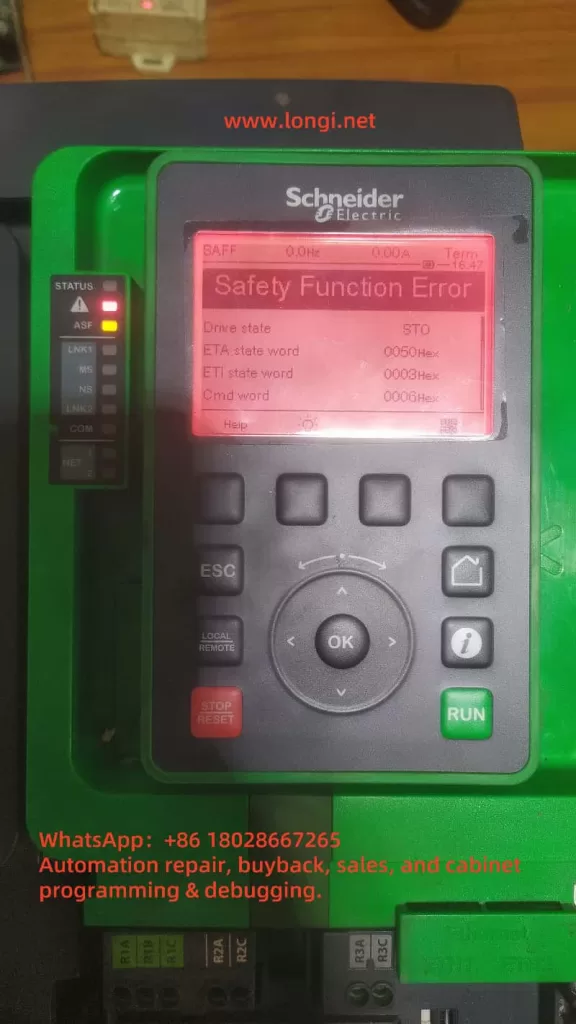

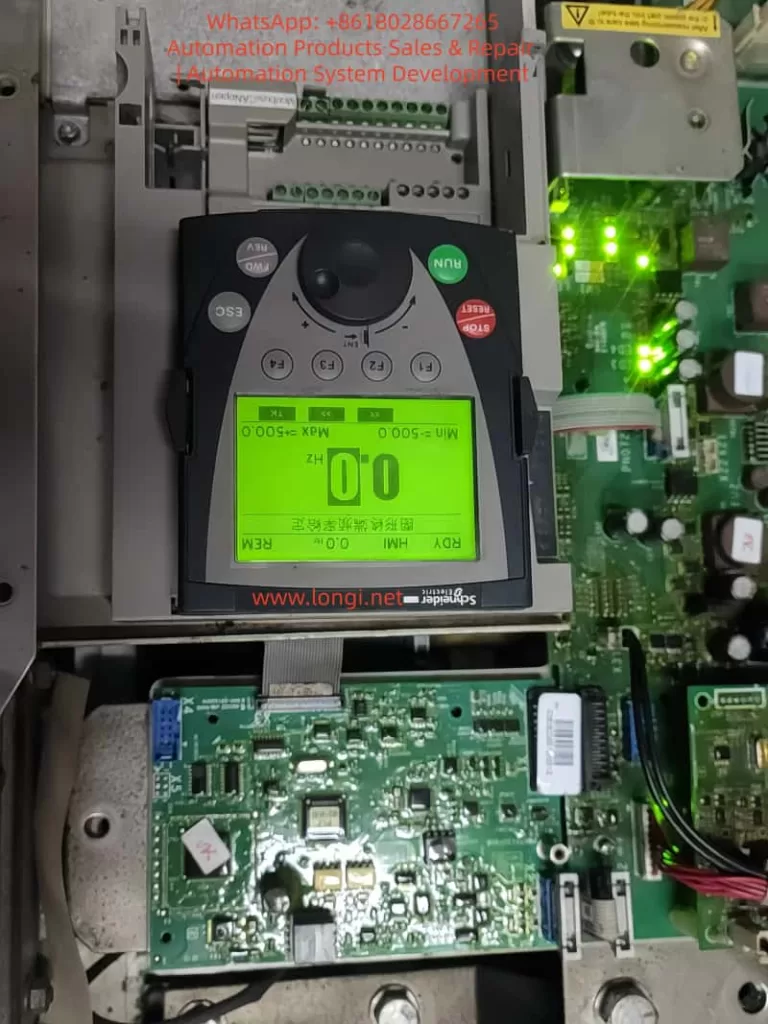

The integrated HMI of the ATV71 uses a seven-segment LED display. The SSF fault code may be misread as “S5F” or “55F” due to display aging, dust coverage, or improper viewing angles. The official manual clearly states that SSF is a torque or current limitation fault, and users can view the actual fault code through the graphic terminal or SoMove software to confirm.

III. Triggering Mechanism of SSF Fault

The control algorithm of the ATV71 continuously monitors the output current and estimates the torque in real time. When the actual current reaches or exceeds the current limit value (CLI), or the estimated torque reaches or exceeds the torque limit value, and the duration exceeds the set timeout time (Sto), the drive will trigger the SSF fault and shut down.

IV. Common Causes of SSF Fault

Mechanical Load Aspect

- Sudden increase in load

- Increased mechanical friction

- Changes in the inertia of the transmission system or process variations

Improper Parameter Configuration

- Excessively short Sto setting

- Current/torque limit values set too low

- Incorrect motor nameplate parameters or excessively short acceleration/deceleration times

Control Mode and Tuning Issues

- Failure of sensorless vector control tuning

- Using V/F control for high-inertia loads or improper PID control parameters

Electrical and Environmental Factors

- Power supply voltage fluctuations

- High ambient temperature

- Excessively long output cables or parallel operation of multiple motors

Potential Hardware Problems

- Aging of IGBT modules

- Drift of current sensors or control board failures

V. Diagnostic Process for SSF Fault

On-site Preliminary Confirmation

- Record the operating state at the time of the fault occurrence, check the fault history, and monitor the current, torque, output frequency, and drive thermal state at the moment of the fault.

Parameter Check and Temporary Adjustment

- Adjust the Sto parameter, check the current and torque limit values, confirm the motor parameters, and perform automatic tuning.

Mechanical System Inspection

- Manually rotate the shaft to check for mechanical jamming, inspect the transmission components, and measure the actual load current.

Electrical Testing

- Check the stability of the input voltage, measure the balance of the motor’s three-phase currents, and consider adding an output reactor.

Advanced Diagnosis

- Use SoMove software to view real-time curves, execute test programs, and contact Schneider service.

VI. Troubleshooting and Solutions for SSF Fault

Parameter Optimization

- Increase the Sto value, raise the CLI, set the torque limit value reasonably, and extend the acceleration/deceleration times.

Mechanical System Improvement

- Lubricate the bearings, adjust the belt tension, clear blockages, and optimize the process load.

Control Strategy Adjustment

- Perform a complete automatic tuning, optimize the PID parameters, and switch to closed-loop control with an encoder.

Hardware Supplementation

- Add an output reactor, enhance cooling or operate at a reduced rating, and add a braking unit/resistor.

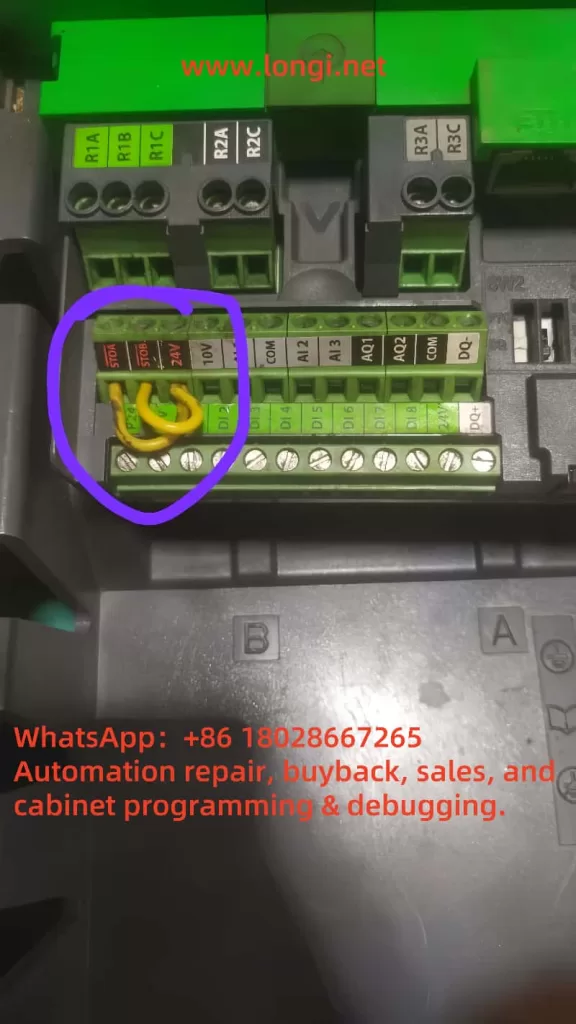

Reset Methods

- Press the panel STOP/RESET key, reset through an assigned digital input, or enable the automatic restart function.

VII. Typical Case Studies

Conveyor Belt Application

- Problem: During startup, a sudden increase in coal volume caused the current to瞬间 (momentarily) reach 160% and remain for 2 seconds, with the original Sto set at 100 ms.

- Solution: Change the Sto to “Cont” and optimize the material loading process.

Constant-pressure Water Supply in a Pump Station

- Problem: One pump’s impeller was entangled with debris, causing uneven load.

- Solution: Clean the impeller, redistribute the load, and increase the Sto value.

Crane Hoisting

- Problem: During the deceleration phase, regenerative energy triggered the torque limit.

- Solution: Set the reverse torque limit reasonably and add a braking resistor.

Fan Application

- Problem: In a high-temperature workshop during summer, the drive automatically derated.

- Solution: Strengthen the ventilation of the cabinet and install an air conditioner.

VIII. Preventive Measures for SSF Fault

Parameter Rationalization

- Adjust the Sto value before the commissioning of a new project and reserve current/torque margins.

Regular Maintenance

- Regularly inspect the mechanical transmission system, clean the drive’s radiator, perform motor insulation tests, and execute automatic tuning.

Monitoring and Early Warning

- Continuously monitor the current/torque curves and provide early warnings when approaching the limit state.

Training and Documentation

- Establish standard operating procedures and save parameter modification records.

IX. Conclusion

Although the SSF fault is common, it can be quickly resolved through systematic analysis and targeted measures. Proper handling of the SSF not only eliminates the fault but also improves system stability and efficiency. It is recommended to use the official programming manual as the standard in actual maintenance, conduct in-depth diagnosis with the help of SoMove software, and promptly contact Schneider Electric technical support for professional solutions.