-

ebm-papst RG148/1200-3633 EC Centrifugal Fan 230V 140W Used Industrial Blower (Made in Germany)

$123.00 Add to cart -

KEB F5 Frequency Inverter 75kW | Model: 23F5A1R-YVC2 | For Haitian Injection Molding Machine

$3,125.00 Add to cart -

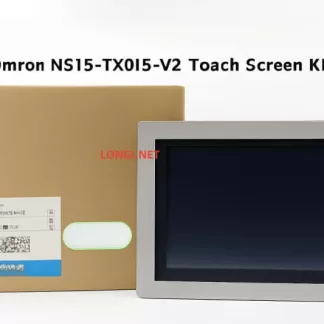

Omron NS15-TX01S-V2 Touch Screen HMI Brand New Stock, Quality Guaranteed

$3,125.00 Add to cart -

Omron NS15-TX01B-V2 Touch Screen HMI Used – Like New Condition

$3,125.00 Add to cart -

Shipping Fee Supplement | Extra Freight Charge | Logistics Payment

$1.00 Add to cart -

ABB ASFC-01C Switch Fuse Controller,Used

$278.00 Add to cart

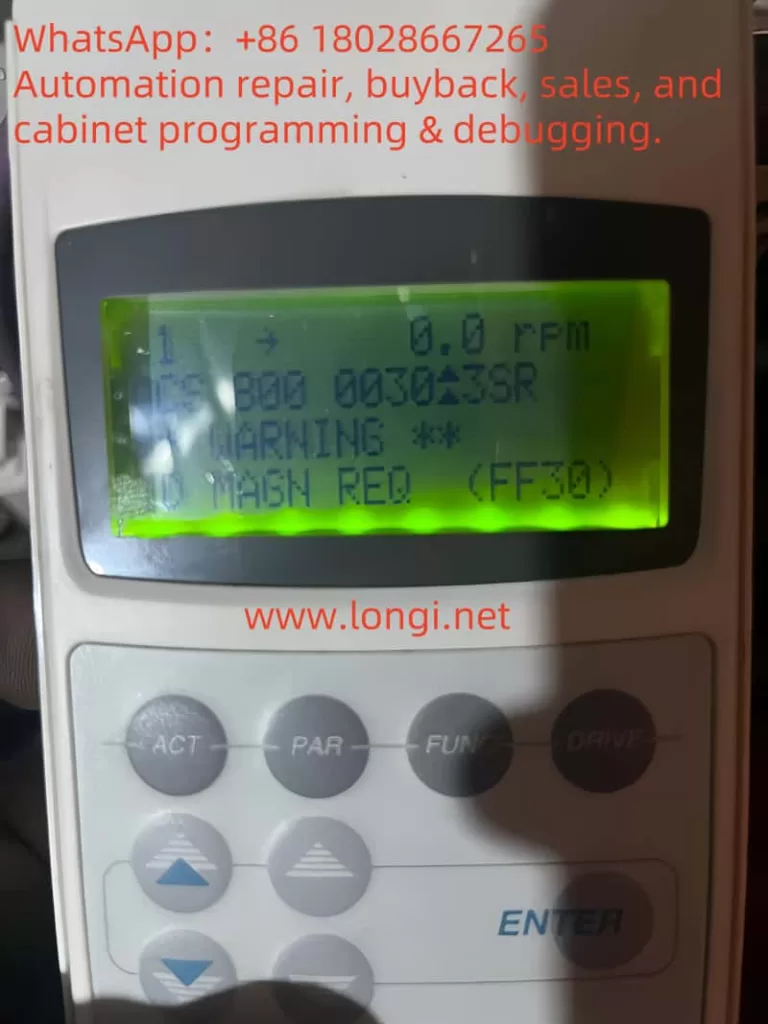

Introduction: Overview of ABB ACS800 Inverters

The ABB ACS800 series of inverters are high-performance industrial devices widely used in manufacturing, mining, water treatment, and other industries. Their core advantage lies in Direct Torque Control (DTC) technology, which enables precise speed and torque control, making them suitable for various complex applications. However, during operation, users may encounter the FF30 warning “ID MAGN REQ,” a common prompt indicating the need for motor identification and magnetization. This article delves into the meaning, causes, and solutions for the FF30 warning, providing detailed operational steps to help users resolve the issue promptly.

Meaning of the FF30 Warning “ID MAGN REQ”

The FF30 warning “ID MAGN REQ” indicates that the inverter needs to identify and magnetize the connected motor. Motor identification is a process where the inverter measures the motor’s electrical characteristics (such as resistance and inductance) to establish an accurate model. This model is crucial for DTC control, ensuring efficient and precise motor operation.

The warning typically appears in the following scenarios:

- Initial Startup: After entering motor data in parameter group 99 (Startup Data), the inverter prompts for identification.

- Motor Switching: When using user macros to switch between different motors, the inverter requires re-identification of the new motor.

According to the manual, the FF30 warning is a normal part of the startup process, prompting the user to select an identification method: ID Magnetisation or ID Run.

Importance of Motor Identification

Motor identification plays a vital role in inverter operation with the following key functions:

| Function | Description |

|---|---|

| Precise Control | Ensures the inverter adjusts control parameters based on the motor’s actual characteristics, achieving accurate speed and torque control. |

| Efficient Operation | Optimizes motor efficiency, reducing energy consumption. |

| Motor Protection | Sets appropriate protection limits to prevent overcurrent, overheating, and other faults, extending motor life. |

| Support for Special Applications | Enables stable performance in applications requiring zero-speed operation or high torque without speed feedback. |

Motor identification is crucial for ensuring system performance and reliability, especially in ACS800 inverters using DTC control.

Possible Causes of the FF30 Warning

The FF30 warning may be triggered by the following reasons:

- Incomplete Motor Identification: ID Magnetisation or ID Run not performed after initial startup or motor switching.

- Incorrect Motor Parameters: Motor data in parameter group 99 (such as rated voltage, current, frequency) does not match the motor nameplate.

- Wiring Issues: Loose or damaged connections between the motor and the inverter.

- User Macro Switching: Re-identification required after switching user macros in multi-motor applications.

Detailed Steps to Resolve the FF30 Warning

Below are the two primary methods for resolving the FF30 warning: ID Magnetisation and ID Run, along with handling multi-motor scenarios using user macros.

Method 1: ID Magnetisation (Motor Magnetization Identification)

Overview: ID Magnetisation is the process of magnetizing the motor at zero speed, lasting 20–60 seconds, suitable for most applications. It is automatically performed during the inverter’s initial startup.

Operational Steps:

- Check Motor Parameters:

- 99.04: Motor rated voltage

- 99.07: Motor rated current

- 99.06: Motor rated frequency

- 99.08: Motor rated power

- If parameters are incorrect, adjust and save.

- Switch to Local Control Mode:

- Press the LOC/REM key on the control panel until the display shows “L” (Local Control Mode).

- Initiate Magnetization Identification:

- Press the Start key; the inverter begins magnetizing the motor.

- The process lasts 20–60 seconds, during which the display may show relevant warnings.

- Confirm Completion:

- After identification, the display shows “ID DONE,” and the FF30 warning disappears.

Method 2: ID Run (Motor Running Identification)

Overview: ID Run is a more advanced identification method suitable for applications requiring high-precision control, such as zero-speed operation or high torque without speed feedback. ID Run comes in two types:

- STANDARD ID Run: Requires the drive mechanism to be disconnected from the motor, allowing the motor to run freely.

- REDUCED ID Run: Suitable for scenarios where the drive mechanism cannot be disconnected, with slightly lower accuracy.

Operational Steps:

- Check Prerequisites:

- Refer to the ABB ACS800 firmware manual to ensure that ID Run parameter requirements (such as motor stoppage, load conditions) are met.

- Set Parameter 99.10:

- STANDARD: For scenarios where the load can be disconnected.

- REDUCED: For scenarios where the load cannot be disconnected.

- Switch to Local Control Mode:

- Press the LOC/REM key to display “L”.

- Initiate ID Run:

- Press the Start key; the inverter begins running identification.

- The display may show warnings such as “MOTOR STARTS” or “ID RUN”.

- Confirm Completion:

- After identification, the display shows “ID DONE,” and the FF30 warning disappears.

Method 3: Handling Multi-Motor Applications with User Macros

In multi-motor applications, user macros can store parameters for different motors, simplifying the switching process.

Operational Steps:

- Save Motor Parameters:

- After completing identification for one motor, set parameter 99.02 to “USER 1 SAVE” or “USER 2 SAVE” to save the parameters.

- The saving process takes 20–60 seconds.

- Switch Motors:

- Perform identification (ID Magnetisation or ID Run) for the new motor.

- Save the new motor parameters to another user macro slot.

- Load Parameters:

- Load the corresponding motor parameters by setting 99.02 to “USER 1 LOAD” or “USER 2 LOAD”.

- Loading may trigger the FF30 warning again, requiring re-identification.

Troubleshooting and Precautions

If the FF30 warning persists, try the following troubleshooting steps:

| Issue | Troubleshooting Method |

|---|---|

| Incorrect Motor Parameters | Recheck parameter group 99 to ensure it matches the motor nameplate. |

| Wiring Issues | Inspect the cable between the motor and the inverter to ensure connections are secure and undamaged. |

| Transient Fault | Turn off the inverter power, wait a few minutes, and restart. |

| Firmware Issues | Check for available firmware updates on the ABB official website. |

| Complex Application Scenarios | Contact ABB technical support, providing the inverter model, firmware version, and application details. |

Precautions:

- Always follow electrical safety norms; disconnect power before checking wiring.

- Ensure the motor and load are in a safe state when performing ID Run.

- Confirm parameter settings are correct before saving user macros to avoid overwriting important data.

Conclusion

The FF30 warning “ID MAGN REQ” is a common prompt during the normal startup or motor switching process of ABB ACS800 inverters. By performing ID Magnetisation or ID Run, users can quickly resolve the warning, ensuring optimal performance of the inverter and motor. Motor identification not only eliminates the warning but also optimizes control precision, efficiency, and equipment protection. In multi-motor applications, user macros provide a convenient switching solution. If the issue persists, referring to the official manual or contacting ABB support is advisable.

By correctly understanding and addressing the FF30 warning, users can fully leverage the potential of the ACS800 inverter, providing stable and efficient power support for industrial applications.