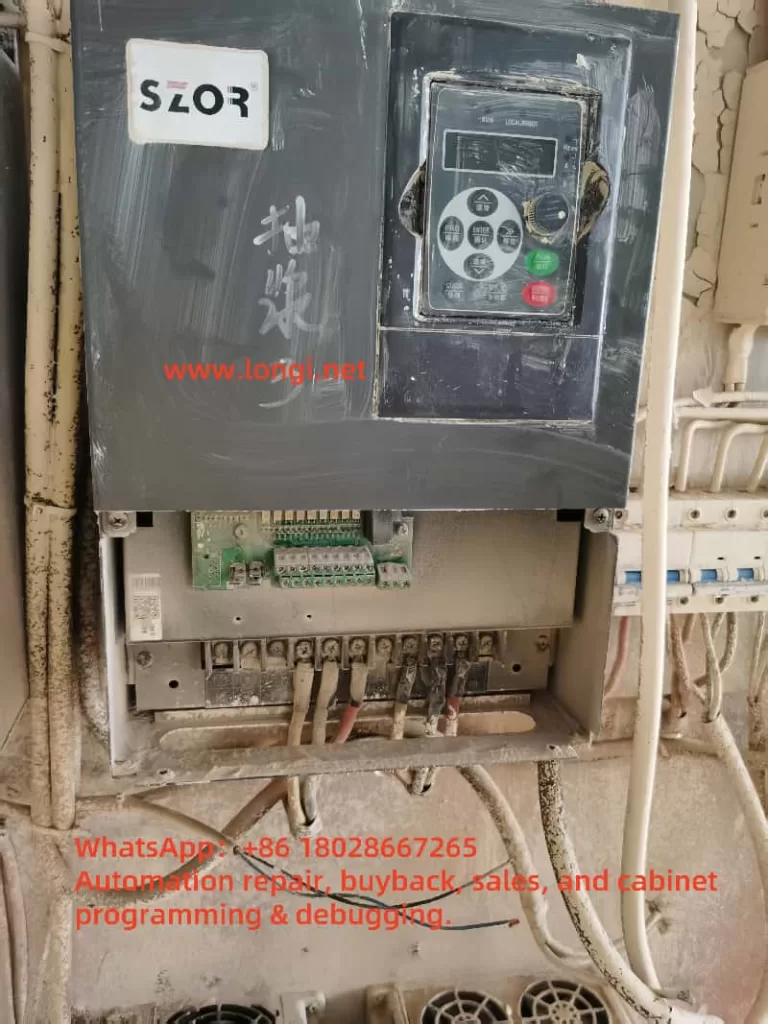

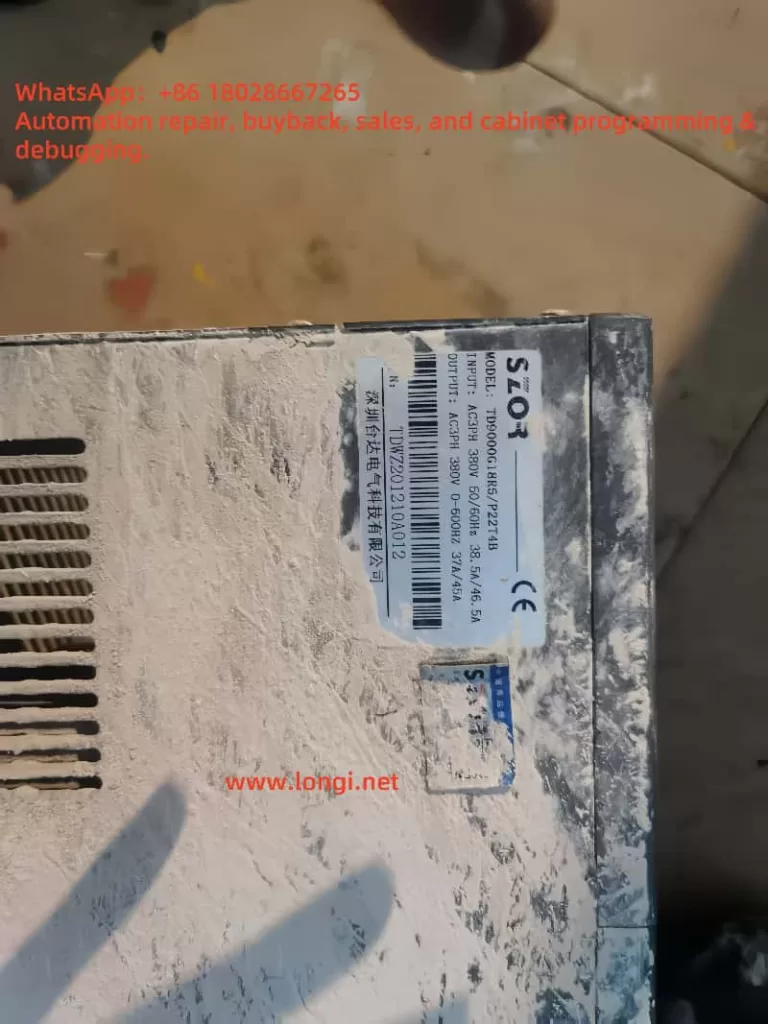

The TD9000 series inverter, developed by SZOR Shenzhen Delta, is a high-performance, highly stable general-purpose drive. It is widely used in applications such as fans, pumps, conveyors, and machine tools. This article introduces the key functions of the TD9000 inverter, including the control panel, password settings, parameter restrictions, parameter initialization, terminal control wiring, potentiometer speed adjustment, and fault diagnostics. It aims to help users operate and maintain the TD9000 series more efficiently and safely.

1. Control Panel Functions

The TD9000 inverter features an LED digital display and keypad panel. Key functions include:

- RUN: Starts the inverter.

- STOP/RESET: Stops operation or resets a fault.

- PROG: Enters or exits the parameter menu.

- DATA/ENTER: Confirms parameter modifications.

- ▲/▼: Scrolls through parameters or adjusts values.

The panel displays parameter codes, output frequency, current, voltage, and other running data. It also supports copy functions to clone parameters from one drive to another, making batch configuration fast and convenient.

2. Password Setup and Parameter Access Restrictions

To prevent unauthorized changes, the TD9000 offers password protection and access-level control.

1. Set Password

- Parameter P00.08:

- Set to

0000: No password protection. - Set to a 4-digit code (e.g.,

1234): Enables password protection.

- Set to

2. Remove Password

- If the password is forgotten, hold down special key combinations (e.g., PROG + STOP) during power-up or access maintenance mode to reset it (should be done by qualified personnel).

3. Parameter Access Restriction

- P00.07: Limits access to basic parameter groups only.

- P00.12 = 1: Activates user-access mode to restrict changes to key parameters.

3. Restoring Factory Settings

To initialize all parameters:

- Set P00.13 = 1 to restore factory defaults. The inverter will reboot automatically. Use with caution, as all settings will be erased.

4. Terminal Forward/Reverse Control & External Potentiometer Speed Adjustment

The TD9000 supports terminal-based control and analog input via external potentiometers.

1. Forward/Reverse Terminal Wiring

- Terminals:

- S1: Forward run command (default).

- S2: Reverse run command (customizable).

- COM: Common ground.

- Parameter Settings:

- F00.06 = 2 (terminal control mode).

- F10.00 = 1 (S1 = Forward).

- F10.01 = 2 (S2 = Reverse).

Closing the respective terminal switch triggers forward or reverse operation.

2. Potentiometer Speed Control Wiring

- Wiring:

- 10V: Power supply to potentiometer.

- AI1: Signal input from potentiometer center tap.

- GND: Ground.

- Parameters:

- F00.05 = 1 (set AI1 as frequency reference).

- Fine-tuning via F11.00 ~ F11.02.

Adjusting the potentiometer varies the output frequency for smooth speed control.

5. Fault Codes and Troubleshooting

TD9000 has advanced fault diagnostics. Faults are displayed as “ErrXX” codes on the panel.

| Code | Meaning | Causes | Solution |

|---|---|---|---|

| Err01 | Overcurrent | Short circuit, too short accel time | Check wiring, increase accel time |

| Err02 | Overvoltage | Grid surge, braking circuit issues | Install brake resistor, adjust voltage |

| Err04 | Overload | Heavy load, frequent starts/stops | Reduce load, optimize control sequence |

| Err05 | Overheat | Fan failure, high ambient temp | Clean fan, improve ventilation |

| Err08 | Communication error | Poor RS485 wiring or parameter mismatch | Check communication settings and wiring |

| Err09 | Input phase loss | Missing phase, grid imbalance | Check power input and phase integrity |

| Err10 | Output phase loss | Broken cable or terminal loose | Inspect output wiring and motor leads |

Press STOP/RESET or cycle power to clear most transient faults. If faults persist, consult service engineers.

6. Conclusion and Best Practices

The TD9000 inverter series is versatile and user-friendly. Key suggestions for optimal use:

- Backup parameters regularly.

- Assign user-level passwords.

- Ensure proper cooling and dust-free environment.

- Follow all safety and wiring instructions in the manual.

By following this guide, users can effectively configure and troubleshoot the TD9000 inverter series for reliable industrial performance.