I. Phenomenon Review

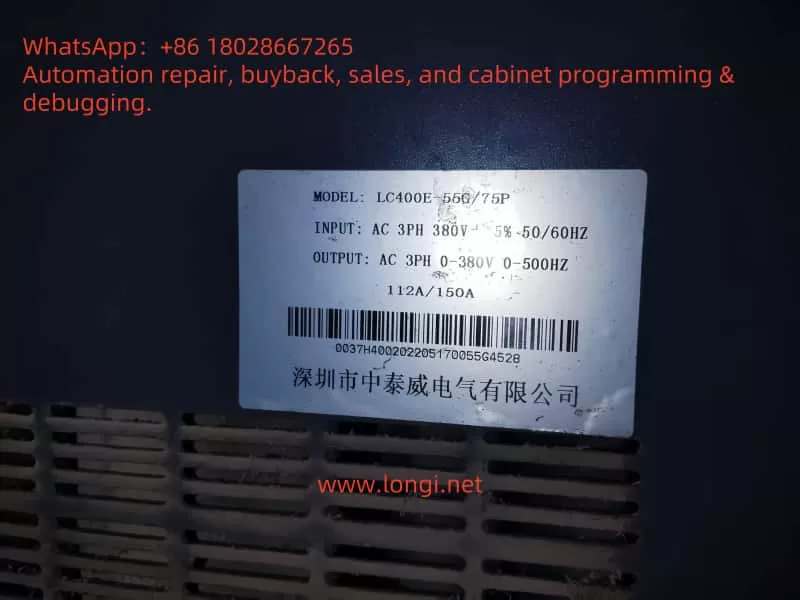

After power-on, the panel alternately displays “‑L‑C‑” and the A29/Err29 code. According to the corresponding entry in the manual:

“Cumulative Power-On Time Reaches Fault Err29 — ① The cumulative power-on time has reached the preset value; ② Use the parameter initialization function to clear the recorded information” (see user screenshot).

This indicates that it is not a hardware failure but rather a software logic lock: when the internally recorded Power-On Time (cumulative power-on hours) exceeds the manufacturer’s preset threshold, the inverter actively enters a protection/shutdown state until the user performs a “parameter initialization” or other unlocking action.

II. Why the “Running Hours Lock” Exists

Driven by Business Models

Some low-cost domestic brands adopt a “runtime limit” strategy, treating inverters as “quasi-leased” equipment:

- The device is shipped with the main machine in the first year, and after 8,000 to 10,000 hours of operation, it locks, requiring the customer to pay the remaining balance or renew the subscription to obtain authorization for reset.

Post-Sales Risk Control

In the “semi-OEM” market, manufacturers find it difficult to control the final application environment. Binding the lifespan limit to the software layer can compress the warranty scope and reduce large claims due to the burnout of high-power components caused by overloading.

Spare Parts Sales and Brand Loyalty

Forces end-users to return to the original manufacturer or authorized repair points for “unlocking + maintenance,” driving sales of spare parts and upgrade packages.

III. Triggering Mechanism Principle of A29/Err29

MCU-Integrated EEPROM/Flash Timer Writing to “Cumulative Power-On Counter”

- During power-on self-check, compare the Counter with the Limit.

- If ≥ Limit → Set Fault Flag → Output relay disconnects, and the panel reports Err29.

- Even after power-off and restart, the counter value remains saved in the EEPROM, so the fault “sticks” unless Parameter Initialize is executed or new firmware is flashed.

⚠️ Unlike ordinary faults (such as phase loss or overcurrent, which are instantaneous alarms), Err29 completely prohibits inverter output before reset, so the motor will not run, and the LED only cycles through error codes.

IV. Troubleshooting and Reset Steps from an Engineer’s Perspective

| Step | Operation Points | Purpose |

|---|---|---|

| 1. Confirm the model’s firmware version | Some versions hide the runtime limit menu; read the EEPROM to check; query the version number via the panel or serial command. | Determine if direct initialization is supported. |

| 2. Back up all parameters | Use the keyboard to copy or serial software to export the parameter table. | Prevent the loss of process recipes after initialization. |

| 3. Execute “Parameter Initialization” | Menu path: System Settings → Parameter Management → Initialize (refer to the manual for specific key sequences). After execution, the counter is automatically erased, and factory defaults are restored. | Clear the cumulative power-on time and resolve Err29. |

| 4. Rewrite the backed-up parameters | Check item by item according to the backup table or use a PC debugging tool to write back in batches. | Restore the original logic and process limits. |

| 5. Test run & observe the counter | Run for a short time to confirm no recurrence of A29; if the counter value still rises rapidly, check the motherboard’s RTC/timing interrupt for abnormalities. | Rule out hardware timing circuit faults. |

V. Bypassing and Deep Modifications (Advanced Topics, for Reference Only)

Under legal and compliant premises, the following practices are common in authorized service centers or when users have terminated the after-sales agreement with the manufacturer:

Modify the Counter Threshold

- Directly increase the Limit in engineering mode (e.g., to 99,999 h).

- Drawback: In some older firmware versions, the threshold is hardcoded, and the menu is hidden.

Rewriting the EEPROM

- Use ISP or offline programmer to read the EEPROM image, manually modify the counter bytes, and then write back.

- Requires disassembly and possession of electronic soldering and programming tools.

Flashing Time-Unlimited Firmware

- Official “overseas” or “engineering test” firmware often removes the runtime limit; after replacing the entire MCU Flash, the limit is completely removed.

- Risk: Flashing failure may brick the device; may involve copyright issues.

VI. Impact on Enterprise Operations and Maintenance

| Impact Point | Description | Coping Strategy |

|---|---|---|

| Production Downtime Loss | Accidental triggering of Err29 can lead to a complete line shutdown. | Include “running hours warning” monitoring in the PM plan to arrange maintenance windows in advance. |

| Maintenance Costs | If unauthorized, need to pay for unlocking or replace the entire unit. | Sign a long-term maintenance package with the manufacturer or train in-house technicians to master initialization skills. |

| Spare Parts Warehousing | Frequent lockouts increase the demand for backup units. | Equip key processes with hot backup drives to reduce the impact of lockouts on production capacity. |

VII. Legal and Ethical Discussion

Software Lock vs. Contract Law: If the sales contract does not explicitly state the “runtime limit lock,” the manufacturer’s setting of software obstacles may violate the “right to know” clause of the Consumer Rights and Interests Protection Law.

Right-to-Repair: Internationally, more and more countries emphasize users’ right to repair their purchased equipment independently, opposing excessive software restrictions. Designs like “Err29” may face compliance reviews in European and American markets.

Balanced Viewpoint: Manufacturers use software locks to prevent equipment from continuing to operate in harsh environments beyond their designed lifespan, potentially causing safety accidents; however, they should disclose this protection logic transparently in advance and provide officially authorized ways to remove it.

VIII. Conclusion and Recommendations

A29/Err29 is not an electrical fault but a “running hours lock.” It can be cleared through “parameter initialization,” but attention must be paid to backing up/restoring process parameters.

It is recommended that enterprises establish a running time ledger and conduct planned maintenance or apply for an official extension of the service package when approaching the threshold to avoid line shutdowns.

For organizations with mature electronic technology teams, evaluating the flashing of time-unlimited firmware or replacing the brand may reduce long-term maintenance costs.

From an industry standard perspective, manufacturers should clearly state this protection logic in the sales contract and manual to maintain supply chain integrity.