Introduction

The Innov-X Alpha series handheld X-ray fluorescence (XRF) spectrometer is an advanced portable analytical device widely used in alloy identification, soil analysis, material verification, and other fields. As a non-radioactive source instrument based on an X-ray tube, it combines high-precision detection, portability, and a user-friendly interface, making it an ideal tool for industrial, environmental, and quality control applications. This guide, based on the official manual for the Innov-X Alpha series, aims to provide comprehensive, original instructions to help users master the device’s techniques from principle understanding to practical operation and maintenance.

This guide is structured into five main sections: first, it introduces the instrument’s principles and features; second, it discusses accessories and safety precautions; third, it explains calibration and adjustment methods; fourth, it details operation and analysis procedures; and finally, it explores maintenance, common faults, and troubleshooting strategies. Through this guide, users can efficiently and safely utilize the Innov-X Alpha series spectrometer for analytical work. The following content expands on the core information from the manual and incorporates practical application scenarios to ensure utility and readability.

1. Principles and Features of the Instrument

1.1 Instrument Principles

The Innov-X Alpha series spectrometer operates based on X-ray fluorescence (XRF) spectroscopy, a non-destructive, rapid method for elemental analysis. XRF technology uses X-rays to excite atoms in a sample, generating characteristic fluorescence signals that identify and quantify elemental composition.

Specifically, when high-energy primary X-ray photons emitted by the X-ray tube strike a sample, they eject electrons from inner atomic orbitals (e.g., K or L layers), creating vacancies. To restore atomic stability, electrons from outer orbitals (e.g., L or M layers) transition to the inner vacancies, releasing energy differences as secondary X-ray photons. These secondary X-rays, known as fluorescence X-rays, have energies (E) or wavelengths (λ) that are characteristic of specific elements. By detecting the energy and intensity of these fluorescence X-rays, the spectrometer can determine the elemental species and concentrations in the sample.

For example, iron (Fe, atomic number 26) emits K-layer fluorescence X-rays with an energy of approximately 6.4 keV. Using an energy-dispersive (EDXRF) detector (e.g., a Si-PiN diode detector), the instrument converts these signals into spectra and calculates concentrations through software algorithms. The Alpha series employs EDXRF, which is more suitable for portable applications compared to wavelength-dispersive XRF (WDXRF) due to its smaller size, lower cost, and simpler maintenance, despite slightly lower resolution.

In practice, the X-ray tube (silver or tungsten anode, voltage 10-40 kV, current 5-50 μA) generates primary X-rays, which are optimized by filters before irradiating the sample. The detector captures fluorescence signals, and the software processes the data to provide concentration analyses ranging from parts per million (ppm) to 100%. This principle ensures accurate and real-time analysis suitable for element detection from phosphorus (P, atomic number 15) to uranium (U, atomic number 92).

1.2 Instrument Features

The Innov-X Alpha series spectrometer stands out with its innovative design, combining portability, high performance, and safety. Key features include:

- Non-Radioactive Source Design: Unlike traditional isotope-based XRF instruments, this series uses a miniature X-ray tube, eliminating the need for transportation, storage, and regulatory issues associated with radioactive materials. This makes the instrument safer and easier to use globally.

- High-Precision Detection: It can measure chromium (Cr) content in carbon steel as low as 0.03%, suitable for flow-accelerated corrosion (FAC) assessment. It accurately distinguishes challenging alloys such as 304 vs. 321 stainless steel, P91 vs. 9Cr steel, Grade 7 titanium vs. commercially pure titanium (CP Ti), and 6061/6063 aluminum alloys. The standard package includes 21 elements, with the option to customize an additional 4 or multiple sets of 25 elements.

- Portability and Durability: Weighing only 1.6 kg (including battery), it features a pistol-grip design for one-handed operation. An extended probe head allows access to narrow areas such as pipes, welds, and flanges. It operates in temperatures ranging from -10°C to 50°C, making it suitable for field environments.

- Smart Beam Technology: Optimizes filters and multi-beam filtering to provide industry-leading detection limits for chromium (Cr), vanadium (V), and titanium (Ti). Combined with an HP iPAQ Pocket PC driver, it enables wireless printing, data transmission, and upgrade potential.

- Battery and Power Management: A lithium-ion battery supports up to 8 hours of continuous use under typical cycles, powering both the analyzer and iPAQ simultaneously. Optional multi-battery packs extend usage time.

- Data Processing and Display: A high-resolution color touchscreen with variable brightness adapts to various lighting conditions. It displays concentrations (%) and spectra, supporting peak zooming and identification. With 128 Mb of memory, it can store up to 20,000 test results and spectra, expandable to over 100,000 via a 1 Gb flash card.

- Multi-Mode Analysis: Supports alloy analysis, rapid ID, pass/fail, soil, and lead paint modes. The soil mode is particularly suitable for on-site screening, complying with EPA Method 6200.

- Upgradeability and Compatibility: Based on the Windows CE operating system, it can be controlled via PC. It supports accessories such as Bluetooth, integrated barcode readers, and wireless LAN.

These features make the Alpha series excellent for positive material identification (PMI), quality assurance, and environmental monitoring. For example, in alloy analysis, it quickly provides grade and chemical composition information, with an R² value of 0.999 for nickel performance verification demonstrating its reliability. Overall, the series balances speed, precision, and longevity, offering lifetime upgrade potential.

2. Accessories and Safety Precautions

2.1 Instrument Accessories

The Innov-X Alpha series spectrometer comes with a range of standard and optional accessories to ensure efficient assembly and use of the device. Standard accessories include:

- Analyzer Body: Integrated with an HP iPAQ Pocket PC, featuring a trigger and sampling window.

- Lithium-Ion Batteries: Two rechargeable batteries, each supporting 4-8 hours of use (depending on load). The batteries feature an intelligent design with LED indicators for charge level.

- Battery Charger: Includes an AC adapter supporting 110V-240V power. Charging time is approximately 2 hours, with status lights indicating progress (green for fully charged).

- iPAQ Charging Cradle: Used to connect the iPAQ to a PC for data transfer and charging.

- Standardization Cap or Weld Mask: A 316 stainless steel standardization cap for instrument calibration. A weld mask (optional) allows shielding of the base material, enabling analysis of welds only.

- Test Stand (Optional): A desktop docking station for testing small or bagged samples. Assembly includes long and short legs, upper and lower stands, and knobs.

Optional accessories include a Bluetooth printer, barcode reader, wireless LAN, and multi-battery packs. These accessories are easy to assemble; for example, replacing a battery involves opening the handle’s bottom door, pulling out the old battery, and inserting the new one; the standardization cap snaps directly onto the nose window.

2.2 Safety Precautions

Safety is a top priority when using an XRF spectrometer, as the device involves ionizing radiation. The manual emphasizes the ALARA principle (As Low As Reasonably Achievable) for radiation exposure and provides detailed guidelines.

- Radiation Safety: The instrument generates X-rays, but under standard operation, radiation levels are <0.1 mrem/hr (except at the exit port). Avoid pointing the instrument at the human body or conducting tests in the air. Use a “dead man’s trigger” (requires continuous pressure) and software trigger locks. The software’s proximity sensor detects sample presence and automatically shuts off the X-rays within 2 seconds if no sample is detected.

- Proper Use: Hold the instrument pointing at the sample, ensuring the window is fully covered. Use a test stand for small samples to avoid handholding. Canadian users require NRC certification.

- Risks of Improper Use: Handholding small samples during testing can expose fingers to 27 R/hr. Under continuous operation, the annual dose is far below the OSHA limit of 50,000 mrem, but avoid any bodily exposure.

- Warning Lights and Labels: A green LED indicates the main power is on; a red probe light stays on during low-power standby and flashes during X-ray emission. The back displays a “Testing” message. The iPAQ has a label warning of radiation.

- Radiation Levels: Under standard conditions, the trigger area has <0.1 mrem/hr; the port area has 28,160 mrem/hr. Radiation dose decreases with the square of the distance.

- General Safety Precautions: Retain product labels and follow operating instructions. Avoid liquid spills, overheating, or damaging the power cord. Handle batteries carefully, avoiding disassembly or exposure to high temperatures.

- Emergency Response: If X-ray lockup is suspected, press the rear switch to turn off the power or remove the battery. Wear a dosimeter badge to monitor exposure (recommended for the first year of use).

- Registration Requirements: Most states require registration within 30 days, providing company information, RSO name, model (Alpha series), and parameters (40 kV, 20 μA). Innov-X provides sample forms.

Adhering to these precautions ensures safe operation. Radiation training includes time-distance-shielding policies and personal monitoring.

3. Calibration and Adjustment of the Instrument

3.1 Calibration Process (Standardization)

Standardization is a core calibration step for the Alpha series, ensuring instrument accuracy. It should be performed after each hardware initialization or every 4 hours, with an automatic process lasting approximately 1 minute.

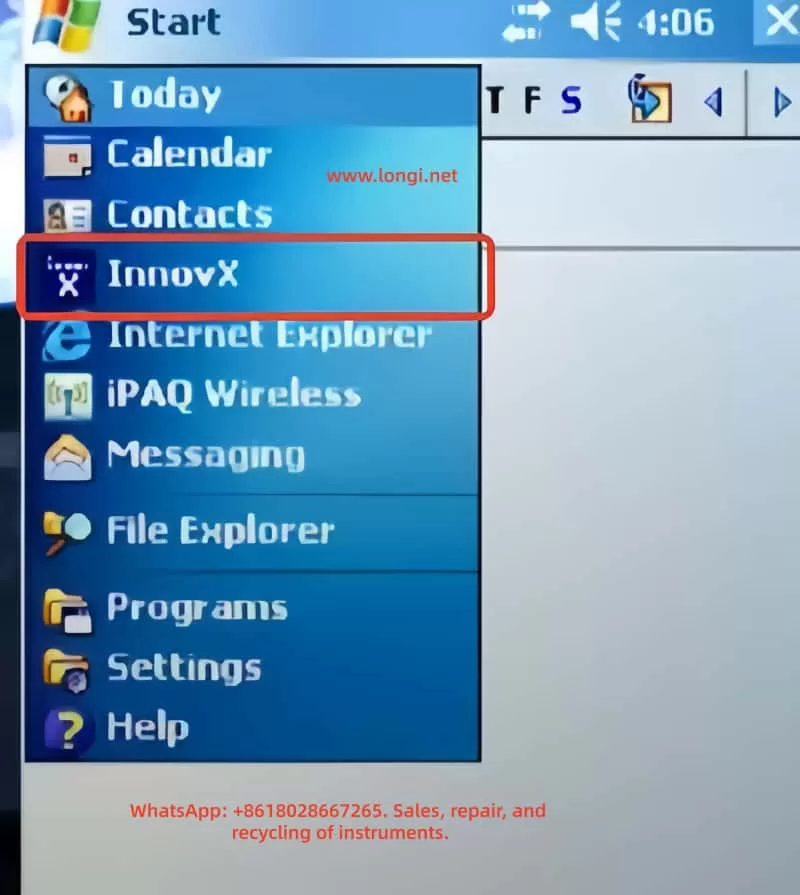

- Preparation: Install a fully charged battery, press the rear ON/OFF button and the iPAQ power button to start. Select the Innov-X software from the start menu and choose a mode (e.g., alloy or soil). The software initializes for 60 seconds.

- Executing Standardization: When the analysis screen displays the message “Standardization Required,” snap the 316 stainless steel standardization cap onto the window (ensuring the solid part covers it). Click the gray box or select File→Standardize to start.

- Process Monitoring: The red light flashes, indicating X-ray tube activation. A progress bar shows the progress.

- Completion: Upon success, the message “Successful Standardization” and resolution are displayed. Click OK. Failure displays errors (e.g., “Wrong Material” or “Error in Resolution”); check the cap position and retry. If it fails continuously, restart the iPAQ and instrument or replace the battery.

- After Battery Replacement: If the battery is replaced within <4 hours for <10 minutes, no re-standardization is needed; otherwise, initialize and standardize.

3.2 Adjusting Parameters

Instrument adjustment is primarily performed through the software interface for different modes.

- Test Time Settings: In soil mode, set minimum/maximum times under Options→Set Testing Times (the minimum is the threshold for result calculation, and the maximum is for automatic stopping). The LEAP mode includes additional settings for light element time.

- Test End Conditions: Under Options→Set Test End Condition, choose manual, maximum time, action level (specified element threshold), or relative standard deviation (RSD, percentage precision).

- Password Protection: Administrator functions (e.g., editing libraries) require a password (default “z”). Modify it under Options→Change Password from the main menu.

- Software Trigger Lock: Click the lock icon to unlock; it automatically locks after 5 minutes of inactivity.

- Custom Export: Under File→Export Readings on the results screen, check Customize Export (requires a password) and select field order.

These adjustments ensure the instrument adapts to specific applications, such as requiring longer test times for soil screening to lower the limit of detection (LOD).

4. Operation and Analysis Using the Instrument

4.1 Operation Procedure

- Startup: Install the battery, start the analyzer and iPAQ. Select a mode, initialize, and standardize.

- Test Preparation: Unlock the trigger, input test information (Edit→Edit Test Info, supporting direct input, dropdown, or tree menus).

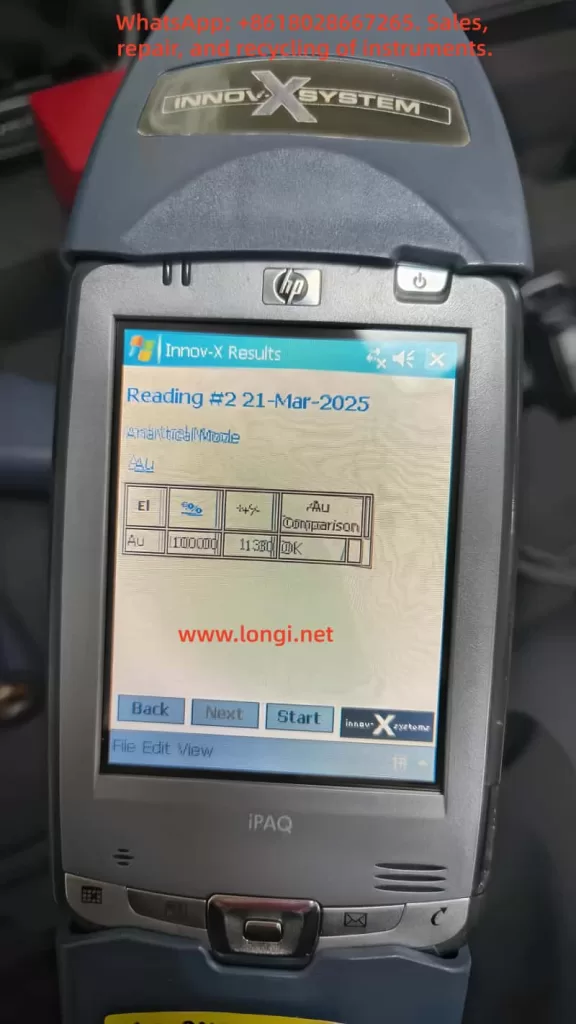

- Conducting a Test: Point at the sample, press the trigger or Start. The red light flashes, and “Testing” is displayed. Results update in real-time (ppm + error in soil mode).

- Ending a Test: Stop manually or automatically (based on conditions). The results screen displays concentration, spectrum, and information.

4.2 Alloy Analysis Mode

- Analysis Screen: Displays mode, Start/Stop, info button, lock, and battery.

- Results Screen: Shows element %, error. Select View→Spectrum to view the spectrum and zoom peaks.

- Rapid ID: Matches fingerprints in the library to identify alloy grades.

4.3 Soil Analysis Mode

- Sample Preparation: For on-site testing, clear grass and stones, ensuring the window is flush with the ground. Use a stand for bagged samples, avoiding handholding.

- Testing: After startup, “Test in progress” is displayed. Intermediate results are shown after the minimum time. Scroll to view elements (detected first, LOD later).

- LEAP Mode: Activate light element analysis (Ti, Ba, Cr) under Options→LEAP Settings. Sequential testing performs standard first, then LEAP.

- Option Adjustments: Set times and end conditions to optimize precision.

4.4 Data Processing

- Exporting: Under File→Export Results on the results screen, select date/mode and save as a csv file.

- Erasing: Under File→Erase Readings, select date/mode to delete.

Operation is straightforward, but adhere to safety precautions and ensure the sample covers the window.

5. Maintenance, Common Faults, and Troubleshooting

5.1 Maintenance

- Daily Cleaning: Wipe the window to avoid dust. Check the Kapton window for integrity; if damaged, replace it (remove the front panel and install a new film).

- Battery Management: Charge for 2 hours; check the LED before use (>50%). Avoid high temperatures and disassembly.

- Storage: Turn off and store in a locked box in a controlled area. Regularly back up data.

- Software Updates: Connect to a PC via ActiveSync and download the latest version.

- Environmental Control: Operate at 0-40°C, 10-90% RH, avoiding condensation. Altitude <2000m.

- Calibration Verification: Daily verification using check standards (NIST SRM) with concentrations within ±20%.

- Warranty: 1 year (or 2 years for specific models), covering defects. Free repair/replacement for non-human damage.

5.2 Common Faults and Solutions

- Software Fails to Start: Check the flash card and iPAQ seating; reset the iPAQ.

- iPAQ Locks Up: Perform a soft reset (press the bottom hole).

- Standardization Fails: Check cap position and retry; replace the battery and restart.

- Results Not Displayed: Check the iPAQ date; erase old data before exporting.

- Serial Communication Error: Reseat the iPAQ, reset it, and restart the instrument.

- Trigger Fails: Check the lock and reset; contact support.

- Kapton Window Damaged: Replace it to prevent foreign objects from entering the detector.

- Calculation Error “No Result”: Ensure the sample is soil type, not metal-dense.

- Results Delay: Erase memory.

- Low Battery: Replace with a fully charged battery.

If faults persist, contact Innov-X support (781-938-5005) and provide the serial number and error message. Warranty service is free for covered issues.

Conclusion

The Innov-X Alpha series spectrometer is a reliable analytical tool. Through this guide, users can comprehensively master its use. With a total word count of approximately 5,600, it is recommended to combine this guide with practical operation exercises. For updates, refer to the official manual.